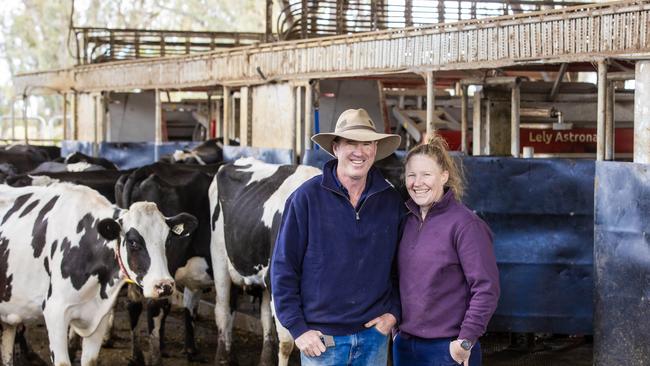

Robotic milking: Myall dairy farmers Tim and Sara McNeil go for growth

Installing a robotic dairy nearly three years ago has proved a winner for Tim and Sara McNeil – but it’s not totally hands off. See the video.

Swapping to robotic milking has meant anything but hands-off for one northern Victorian dairy operation.

And with an unabashed love of cows, Tim and Sara McNeil offer a fascinating blend of hi-tech innovation and hands-on animal husbandry.

Almost three years after transitioning their herd from a 44-unit rotary dairy to robotic milking, the couple has no regrets. They’ve boosted milk solids production per cow, increased milking frequency and improved feed efficiency — all while reducing labour requirements.

The decision to adopt robotic milking wasn’t taken lightly. After 30 years, their rotary dairy needed replacing, and Tim admits they had been considering robots “for a fair while”.

“We needed to go bigger for our milking and there was also the constant issue of finding farm labour,” Sara said.

“All dairy farmers know the tie of milkings twice a day and the robotic milking clearly takes that tie away to a certain extent.”

Eight Lely A5 robotic units — operating as four pairs — were installed in 2022, and the numbers tell the story.

Two years into the transition, the McNeils are now milking 520 cows, up from 455. Those cows are averaging 2.26kg of milk solids per day or 706kg per year, under the robotic system. That’s an increase from 2.03kg per day, or 635kg per year, when using the rotary dairy.

Feed costs have remained steady, at 86c per kilogram of milk solids, while milking frequency has increased to an average of 2.6 to three times a day compared to twice daily with a rotary.

And all this has been achieved with a leaner team — three staff members instead of five.

While the annual production figures and data on the robot dashboard are impressive, there’s also a story behind the transition and the lessons learned in managing the herd during the change.

It all started with the adjustment period needed for the cows to adapt to a new way of being milked.

Sara said the first robotic milking took place in August 2022, and it took about four months for the herd to settle into the new system. That adjustment was partly influenced by the McNeils’ decision to keep cows well fed in the paddocks throughout the transition.

“We had high expectations and we wanted the cows to be fed as much as possible to make as much milk as possible, but what it meant is that the cows weren’t coming back to the dairy,” she said.

“Initially, production actually fell before coming back up in about a month.”

One key lesson the McNeils learned early on was the importance of feeding in the bail to encourage cows to return for milking — rewarding them for their visits to the dairy.

Today, each cow wears an electronic collar and is allocated a set amount of feed in the bail, based on her milk production. A maximum allowance is 12kg of a wheat and protein mix per day. Importantly, this is capped to prevent overfeeding, regardless of how often a cow presents for milking in a 24-hour period.

After milking, cows pass through a gate to access fresh feed. These gates are programmed so that fresh feed is available every six hours.

That prompted another major change on the farm: fencing.

“When we had the rotary and big herd sizes, we pulled out most of the fences and now we are putting them back in,” Sara said.

To support the robotic system, the McNeils have been creating more paddocks, often by simply stringing up a single hot wire.

The cows have taken well to the system — perhaps too well at times.

“We have cows that will come in early to see if they can get access to the new paddock of feed — we recorded once that a cow tried the gate 11 times to see if it was time to get the new feed,” she said.

The annual pastures include Shaftal clover and rye-grass, and the cows graze these for as long as possible — from around March through to October or November. Over summer, they’re moved onto three different feed pads where they’re offered a total mixed ration of pasture silage, orange pulp and cottonseed, fed via a silage wagon.

Despite the increased production, Tim said the cows weren’t fed any differently.

“They are just able to eat more with the 2.6-2.8 milkings a day,” he said.

In fact, the herd is now averaging 2.8 to three milkings per day. But with more frequent milking comes a logistical challenge: milk volume and collection.

“We are looking forward to vat monitoring which Fonterra is trialling, because even with a 20,000-litre vat, we may need the milk truck to come more than once in 24 hours,” Sara said.

“At the moment, there can be too much milk or not enough when the tankers come – if they come 6pm one day and 11pm the next day, that’s when we can run into issues.”

While robotic milking has brought greater flexibility and efficiency, Tim and Sara are quick to point out it hasn’t removed the stress from dairying — it’s simply brought a new set of challenges.

The dashboard that monitors the robotic milking system is both a tool and a stress test. If something goes wrong, a sea of red lights and alarms appears, prompting an immediate log-in to diagnose the issue.

Tim still spends plenty of time in the dairy, ensuring the machines are kept clean — not just for hygiene, but also to protect the sensitive electronics that run the system.

Power outages can pose a major problem, but the McNeils have solved that by running the robotics off-grid, with a backup generator ready to kick in if needed.

The couple describes the move to robotics as a complete lifestyle change — one that isn’t for everyone.

“There is still a lot of work, for while there are no humans involved in the actual milking, we are monitoring and feeding and watching our key performance indicators on the dashboard,” Sara said.

“But we are not tied to the milking twice a day which has offered us quality of life because of that flexibility.

“We’ve also noticed that the cows are less stressed and we have lessened our exposure to injuries with staff that may have happened during milking.”

There’s no turning back now. The old rotary dairy has been pulled down, and the shed will be repurposed to provide shade for cows waiting to be milked.

“We joke that the queues to be milked are sometimes like the queues for the ladies toilets at the MCG,” Sara said.

“But we are convinced it was the right thing to do — the old rotary is now scrap metal so that really says it all.”