Wool growers’ Leroy Mac knit brand defies bushfire tragedy

Lexton Merino producers Rebecca and Rod McErvale talk to Farm magazine about the havoc wreaked on their farm by a blaze last December and the amazing customer support they received.

AS A fourth generation Lexton wool grower, Rod McErvale knew the routine well. Raise the sheep, shear the sheep and send their wool off to be sold.

His was part of a successful family operation and, despite severe bumps in the wool industry road, he might have continued that way.

Then this farmer found a wife, city girl Rebecca.

That was 12 years ago and now with two children, Maddison, 6, and Isla, 4, Rod and Rebecca’s business has dramatically expanded, transforming about a third of its fleece wool into an exciting range of 100 per cent Australian Merino woollen baby blankets, beanies, scarfs and men’s jumpers.

Under the brand Leroy Mac Designs, it has bucked the trend, value-adding to its own wool rather than handing rights overseas.

It’s a fascinating “bringing it all back home” story that has gained the couple a raft of rural marketing and business awards, including Rebecca’s nomination in The Weekly Times Shine Awards.

Click here to read the most recent digital edition of Farm magazine.

Yet the path has not been easy, with numerous hurdles in establishing a production stream and then last December a disastrous bushfire that ripped through their main farm at Lexton, destroying about 28km of fencing and sheep yards and taking the lives of 300 sheep.

Many might have given up, but not these two. Buoyed by post-bushfire support of locals and an upsurge in online sales, they have vowed to push on.

Driving them is the belief their products are among the few truly Australian Merino wool items made from fleece actually grown by the farming business selling them.

“People often buy what they are told is pure Australian Merino wool,” says Rebecca, the marketing brains of the operation.

“But where was the wool sourced? How was it grown?”

Rebecca says it’s near impossible without scientific testing to know a wool garment’s true make-up. Their point of difference is they guarantee, through DNA testing before and after manufacturing, their products are of pure Merino that came from sheep on their land.

“We have full traceability to take a purchaser back to the actual paddock where that wool came from,” they say.

WHERE IT BEGAN

Rebecca, the instigator of Leroy Mac Designs, hit on the idea about 11 years ago.

“When my nephew, the first grandchild of the family, was born we were looking for a pure Merino Australian blanket to buy for him but there was nothing about,” she says.

“They were all blended or made in China, and I said to Rodney ‘why aren’t we doing this? We have got the sheep’.

For a long time they searched unsuccessfully for a local spinner to process their greasy wool into yarn and eventually started producing baby blankets from wool yarn bought from a NSW textile company.

When Rod caught up with an old high school friend who worked as a wool grower for another firm, the solution appeared. The friend had contacts and within a month their first batch, a mere 300kg of greasy wool, was on its way to Italy for processing.

Importantly, the processing company provided DNA testing to guarantee the yarn that came back had been produced solely from the McErvales’ Lexton Merino wool.

They have had three lots of wool processed into yarn in Italy but, because that company changed hands, they have moved to another option.

This time around they are having their greasy wool made into “super wash tops”, making it softer and more easily spun and dyed and allowing it to be machine washed, through Italian company The Schneider Group.

“This will then come back to us here and then Wangaratta Spinning Mills will spin and dye our yarn as we need it to the colours we require,” Rod says.

“The costings are working out a little bit dearer than in the past, but we have so much more control and options available to us.”

Tim Marwedel, the manager of Schneider Australia, and Colin Walker, the owner of Bendigo Woollen Mills and Wangaratta Spinners, have been really helpful.

LOSSES AND COSTS

Sadly last year’s bushfire was a major blow to the business, largely because of sheep losses and the fact they had minimal wool.

“We used to work on a third, a third and a third,” Rod explains. “A third in yarn, a third to get it knitted and we make a third profit, but it ain’t happening now.” As it is, they must make hefty payments well before they see a cent coming back into the business, and they admit their traditional wool sales are subsidising the processing venture.

He sees the solution as a streamlining of systems, reducing processing costs through better production efficiencies.

“It’s all about volume,” he says. “The more we get done, the more money we’ve got to find, but the cost per kilo is cheaper.”

Rod says if they can boost their wool for processing to 10 tonnes a time they could achieve a similar price to local yarn.

“Rather than getting it processed every year, it would be good if we could get to the stage where it is processed every five years,” he says.

Rod and Rebecca’s biggest sales driver is encouraging likely customers to “feel the difference”.

“When we’re at a market and people see the farmer there, a real-deal farmer, and then they see the two products, they’re won over,” Rebecca says. “I say feel this, this is what we used to sell, which is ‘pure Australian Merino’ – and ‘this is our wool from our sheep, and we can tell you what paddock that has been grown in’. People just love hearing the story.”

Rod is proud of an increase in corporate sales, such as a recent one to a local wind farm company. “The yarn for these,” he says proffering a woollen work jumper with the name Stockyard Hill Wind Farm embroidered on it, “came from sheep that ran in the paddock where the wind turbines are now. That’s the way they wanted it.”

While the fire brought their business to its knees, both have been delighted at a recent jump in the sales of woollen products. “We’ve never had sales like we have this year,” marvels Rebecca. “Much of it is online and word of mouth. People have gone ‘whoa, how can we help you?’”

Previously 40 per cent of their sales were made face-to-face at the Talbot Farmers’ Market and at craft and sheep shows, but since COVID, nearly all sales are online.

While Leroy Mac Designs is all about looking forward, these farmers proudly acknowledge the business’ pioneering roots.

Started by Scottish forebear John McErvale on 20 acres in gold rush days, it soon expanded with his four sons taking up parcels of land around him.

“My grandfather was one of those brothers and then my father and his brother took over, and now it’s me,” says Rod who shares the legacy with his brother.

Rod believes his great-grandfather had been a vet brought out from Scotland to tend the flock on a major local landholding. Today a local McErvales Road is testament to the family’s rural Victorian beginnings.

FIRE TRAUMA

Today Rod McErvale is still haunted by the sound of gunfire. It brings back painful memories of so many burnt sheep being put down.

“I’ve never seen him like it,” recalls Rebecca of her husband after the fire on the night of December 20 last year that razed much of their main property at Lexton.

“He couldn’t sleep, it was horrendous.”

Recalls Rod, a member of the local Raglan CFA brigade: “I’ve been in lots of bigger fires but when it’s on your own place at night it’s different. Afterwards the insurance assessor said, ‘Why didn’t you have helicopters, where were the aircraft?’ I said, ‘Mate, they don’t fly in the dark’.

”We pulled it up and then a couple of hours later we couldn’t hold it. The captain reckoned he was doing 80km/h down the road and he couldn’t keep up with it.”

After losing 300 sheep and about 28km of fencing on his property and the neighbouring one owned by his father, Rod believes they would not have been able to continue operating but for the help of BlazeAid volunteers who spent five weeks clearing up burnt fencing.

“BlazeAid is an amazing organisation, absolutely amazing,” he says.

The volunteers all went away with free Leroy Mac beanies, thanks to the knitters donating their time and yarn provided by Rod and Rebecca. Typically too, when the nearby Talbot Farmers’ Market donated the proceeds of a raffle to them, they passed the $1000 to BlazeAid.

“They had just done so much for us,” reasons Rod.

FARM FILE: Leroy Mac Designs

Rebecca and Rod McErvale run sheep on multiple properties across the Lexton-Beaufort area, with two-thirds of their wool being sold in the traditional manner and the remainder processed into yarn to produce a range of pure Merino garments. They shear about 6000 sheep, with a quarter being lambs. Last year they shore about 28,000kg of wool. Their wool products include baby blankets ($210), beanies ($35), scarfs ($45-$50) and jumpers ($180). They also sell yarn to home knitters.

Where: Lexton, Pyrenees

More info: leroymac.com.au

MORE

FIONA AVEYARD FOCUSES ON TULLAMORE OUTBACK LAMB BRAND

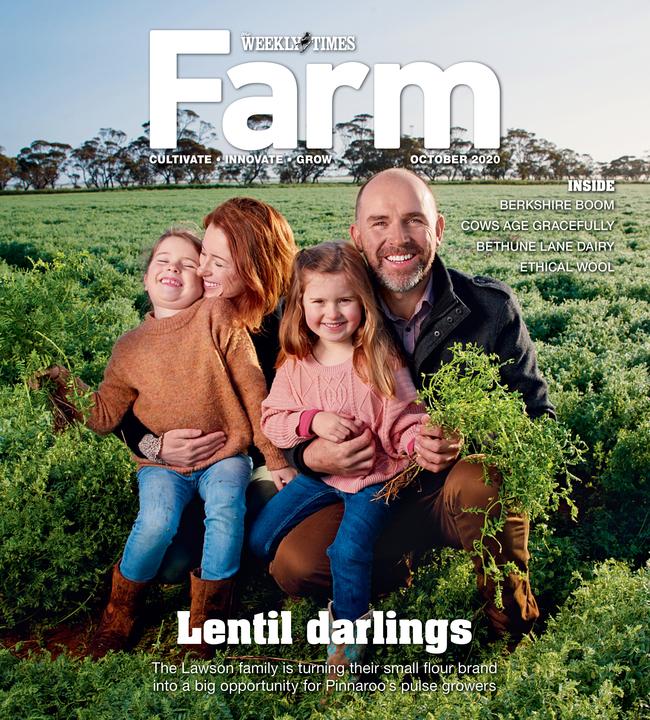

LAWSON FAMILY LAUNCHES THE PINNAROO FARMER RED LENTIL FLOUR

COLOSTRUM CAPSULES GIVE SOUTH GIPPSLAND DAIRY A HEALTHY BOOST