Tesla boss Elon Musk wants Tesla to be the ‘best at manufacturing’

Elon Musk has announced an ambitious plan that he said will ultimately determine the success of the battery and electric vehicle maker.

Hitech

Don't miss out on the headlines from Hitech. Followed categories will be added to My News.

Tesla boss Elon Musk wants the electric vehicle and battery maker to be “the best at manufacturing of any company on Earth” in a bid to bring down electric vehicle costs and accelerate the transition to sustainable energy.

Elon Musk said that will be the company’s goal and how its eventual success is measured.

“By how many years did we accelerate sustainable energy? That’s the true metric of success,” Mr Musk said, adding: “It matters if sustainable energy happens faster or slower.”

“We’re going to run out of these fossil fuels,” Tesla senior vice president of powertrain and energy engineering Drew Baglino said. “Let’s just move to the future and not run this experiment any longer.”

RELATED: Musk dared to put ‘chip in his own brain’

RELATED: Elon thanks worker who foiled ‘serious attack’

Mr Musk said the three focuses of sustainable energy will be around generation, storage, and electric vehicles (EVs).

“We intend to play a significant role in all three.”

He said the transition will require producing more affordable EVs and energy storage as well as building new factories faster while simultaneously spending less on them.

Mr Musk made the comments at Tesla’s “Battery Day”, a long-awaited announcement of new battery technology that followed the companies annual shareholder meeting, which investors viewed from screens inside their Tesla.

RELATED: Tesla planning faster version of Model S

RELATED: ‘Game changer’ for electric cars

The first change he announced is Tesla’s new goal to reach terawatt hour (TWh) scale battery production, noting that “100 per cent electric transportation requires 100 times growth”.

“A terawatt is a thousand times more than a gigawatt, so we used to talk in terms of gigawatts, in the future we’ll be talking about terawatt hours,” Mr Musk said.

But there’s a problem.

“Today’s battery (factories) can’t scale fast enough’ they’re just too small,” Mr Musk said.

He noted Tesla’s so-called “Gigafactory” in Nevada produces around 150GWh per year.

“That’s only 0.15TWh,” Mr Musk noted.

“And it costs too much,” he added.

RELATED: Mystery of Elon Musk’s $2.1 billion bonus

Mr Baglino said that scaling as fast as Tesla “can and should” required a “dramatic rethink of the cell manufacturing system”.

He said Tesla’s vehicles and factories are designed from the ground up to “make the best cars in the world”, before revealing the company would now do the same for batteries, to a chorus of approving horns from the assembled crowd of Teslas.

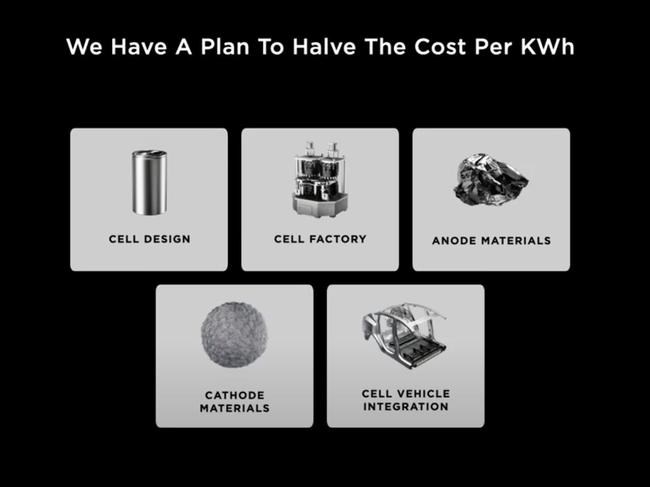

He said Tesla’s plan was to “halve the cost per KWh” of battery production.

This could likely bring Tesla’s production below the $US100/KWh threshold at which point experts believe electric vehicles become more economical than internal combustion vehicles.

Mr Musk said the plan the company has cooked up “thought through almost every element of the battery”.

Doing that has led to the design of a new type of battery cell, which is more powerful and efficient, and which “nobody has done before,” according to Mr Musk.

That design comes in the form of the new “4680” Tesla cell (the numbers refer to the size of the cylindrical battery cell: 46mm in diameter and 80mm tall).

Mr Baglino said the 4680 cell offers “five times the energy with six times the power, and enables a 16 per cent range increase, just on the form factor alone”.

“This is not just a concept or rendering. We are starting to ramp up manufacturing of these cells,” Mr Baglino promised.

Prior to the event Mr Musk said it would probably take until 2022 before the batteries reached widescale production.

The pair also outlined plans for new factories to make these better batteries, which would use a dry process to coat electrodes onto film rather than the traditional wet process, leading to a factory that’s 10 times smaller.

Mr Musk said the dry coating process was “insanely difficult” to scale up but “it’s close to working”.

“There’s a clear path to success but a tonne of work between here and there,” Mr Musk said.

The aim of the new factories is to provide “high-speed continuous motion assembly”.

Mr Baglino said the changes would result in a seven-fold increase in output.

“You would be astounded at how bad most factories are,” Mr Musk said.

He added that only two or three per cent of a factory’s area size does “useful work”, including Tesla’s at Fremont.

“Basically Tesla is planning to be the best at manufacturing of any company on Earth,” Mr Musk said ambitiously.

“This is the thing that’s actually most important in the long run, from a company standpoint and from achieving sustainability as fast as possible.”

Tesla plans to continue working with existing battery cell suppliers like LG, Panasonic and CATL, but also wants to produce 3TWh per year at its own factories by 2030.

Mr Baglino also announced Tesla would move to use silicon instead of graphite.

Silicon holds more lithium but also expands as it is charged, leading to degradation over time in its engineered form.

Tesla is proposing using raw silicon and designing to account for the expansion.

But before you race out to buy a silicon mine, the company also announced it will be looking for a lot of nickel.

The plan is to maximise the amount of nickel and remove cobalt from the batteries, which promises a 15 per cent reduction in production costs.

Mr Musk said he spoke to CEOs of the biggest mining companies and asked them to “please make more nickel”.

The company has also developed a new metal alloy that means the entire rear section of a car can be made as one piece, which costs 40 per cent less and uses 79 fewer parts per car.

Tesla’s planned vertically integrated manufacturing approach promises to bring a 54 per cent range increase for its cars, a 56 per cent reduction in the cost per kilowatt hour, and 69 per cent reduction per gigawatt hour.

“I think it’s pretty nice that investment per GWh reduction is 69 per cent,” Mr Musk joked as Tesla horns honked in the background.

“It will take us probably a year to 18 months to start realising these advantages, and probably to fully realise … three years or thereabouts.

“If we could do this instantly we would; it just really bodes well for the future.”

“What tends to happen as companies get bigger is things tend to slow down. Well actually they’re going to speed up,” Mr Musk said.

“And they’ll have to speed up if we’re going to accelerate the transition to sustainable energy,” Mr Baglino added.

Tesla’s long-term goal is to make around 20 million electric vehicles per year in order to replace “at least one per cent” of the Earth’s total vehicle fleet.

Originally published as Tesla boss Elon Musk wants Tesla to be the ‘best at manufacturing’