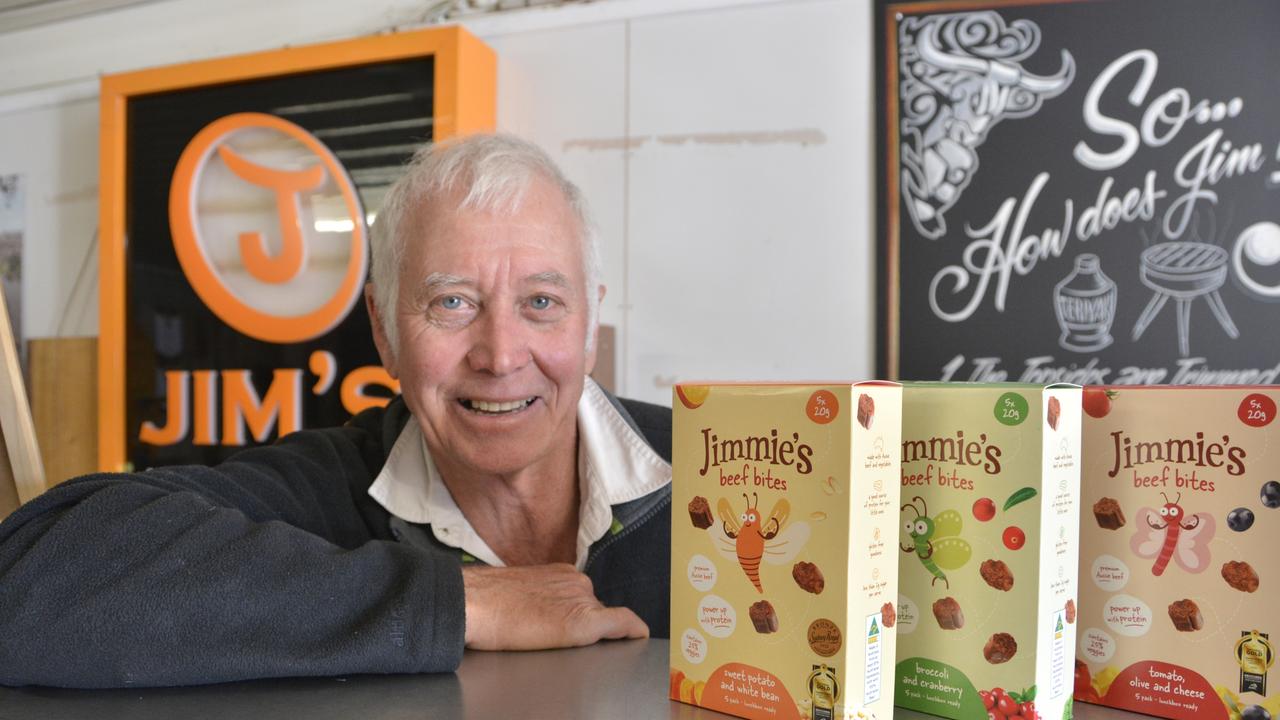

Jim’s Jerky rises from the ashes with new kid lunch box snack

Two months ago, a fire destroyed the equipment Jim’s Jerky relied on to produce its famous products. Now this iconic business is back in production, and keen to give parents a healthy alternative for hungry kids.

Police & Courts

Don't miss out on the headlines from Police & Courts. Followed categories will be added to My News.

Iconic Toowoomba food maker Jim’s Jerky has released a range of snack packs aimed at school lunch boxes.

The fittingly titled Jimmie’s Beef Bites are made of 25 per cent vegetables and 75 per cent Australian beef.

Founder and CEO Jim Tanner said he wanted to make a high-protein snack that did not need refrigeration or contain large amounts of sugar and salt.

“The origins of jerky is that it is beef with the water extracted so everything left over is concentrated,” he said.

“You get a whole lot more protein because you have taken away 60 per cent of the weight which is just water.

“We set out to make a high protein meat and vegetable that tastes good so the kids would actually want to eat them.”

The meat bites come in a range of flavours, including tomato, olive and cheese, or cranberry and broccoli.

They are naturally dried and contain less than gram each of sugar and salt per serve.

“In terms of salt, it is less than white bread and less than tomato sauce,” Jim’s daughter Emily Pullen said.

The release comes just two months after a fire that started from an electrical fault in a motor ignited a gas bottle and poured smoke and soot into the manufacturing floor.

Worryingly it destroyed the business’ three commercial dryers, shutting down production.

“I should have timed the fire much better,” Mr Tanner said.

“I don’t know when the right time for the fire was, but it certainly wasn’t ideal.

“Fortunately we had some Jimmie’s stock made, but we ran short on jerky.”

Being a former farmer, Mr Tanner refused to throw away his first commercial dryer which had been gathering dust until the day after the fire.

“I got it out and introduced myself to it again and said, ‘We have got some work to do,’” he said.

“We spent some money on it and got it up to the standard of the dryers we lost.”

The business is still in the process of having new dryers built and Mr Tanner hoped to be back in full production within six weeks.

He thanked the community and his customers for their support and understanding, including those that dropped off flowers in the aftermath.

“The response was lovely, it was overwhelming,” Mr Tanner said.