GM Steel plans $450m steel mill at Toowoomba, to produce 350k tonnes of rebar annually from southeast Qld scrap metal

Nearly 1000 jobs could be supported by a $450m plan to build Queensland’s first steel mill in three decades in a regional city. Here’s why its founders say the project stacks up:

Development

Don't miss out on the headlines from Development. Followed categories will be added to My News.

Toowoomba could host Queensland’s first new steel mill in three decades as part of a $450m project that could support nearly 1000 jobs during construction and operation.

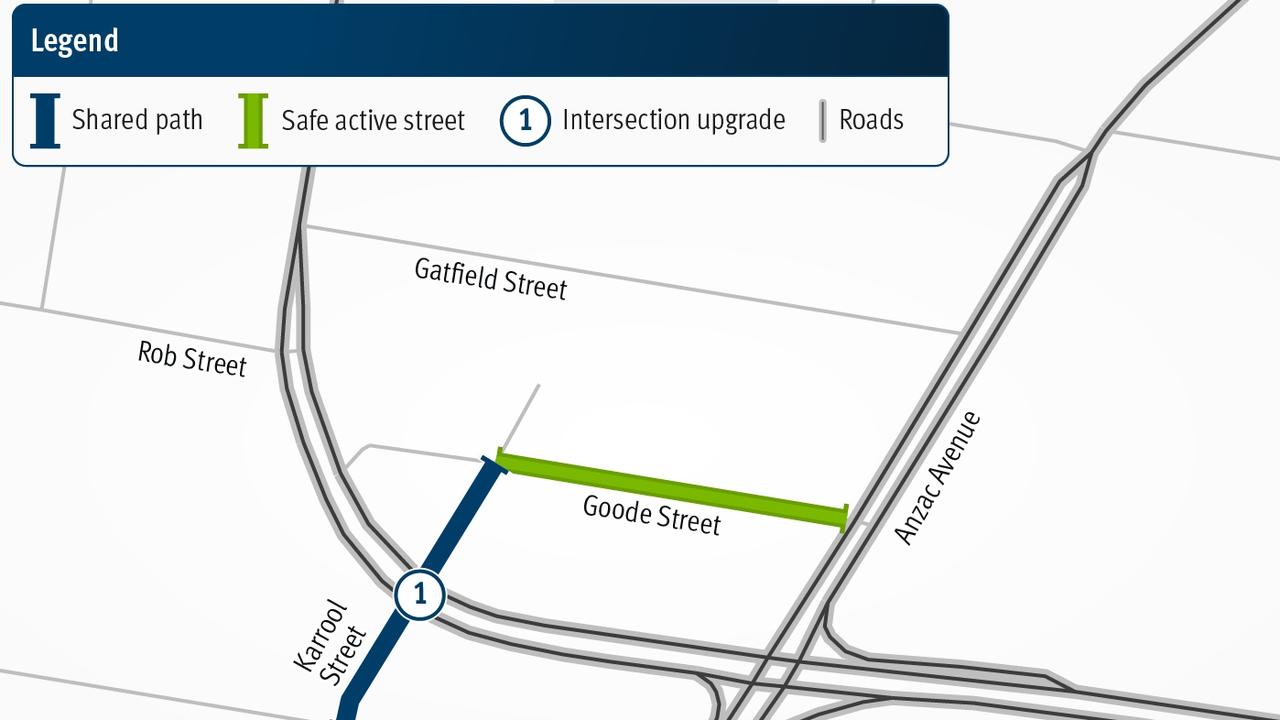

Brisbane firm GM Steel is preparing to lodge plans with the Toowoomba Regional Council for a new 20-hectare “green” steel manufacturing facility on a huge parcel of land on Toowoomba Cecil Plains Road, next to the Toowoomba Bypass, at Wellcamp in the city’s west.

The project, which uses technology by Italian construction manufacturer Danieli that reduces carbon emissions by 85 per cent compared with older methods, would turn scrap metal sourced from southeast Queensland and turn it into 350,000 tonnes of steel rebar every year.

Rebar is a tension device added to concrete to strengthen it as part of building projects, making it a key material in the construction sector.

The firm has already held pre-lodgement meetings with the council’s planning department to help secure a clear path for a development approval (DA), with a view of starting construction in 2026 and a launch by 2027.

GM Steel’s Alan Morgan said the 24/7 mill would support nearly 400 jobs during construction, 500 during operation and be able to heavily service the state government’s planned building boom over the coming decade.

“It’s enough to supply more than 50 per cent of Queensland’s steel requirements each year, just in time to supply unprecedented demand for steel products associated with the state’s Big Build,” he said.

“Using Danieli’s Electric Arc Furnace digital technology to produce steel reduces carbon-emissions by 85 per cent compared with conventional methods such as coal-fired blast furnaces base.”

It comes at a time when Queensland is both exporting 80 per cent of its scrap metal overseas and importing it back as rebar from southeast Asia.

The steel industry is also facing significant pressures following news of financial woes facing British industrialist Sanjeev Gupta’s company InfraBuild.

Planned tariffs on steel by the United States under President Donald Trump also present complications and opportunities.

Mr Morgan, who founded the company in 2023 with Luke Godden after both men enjoyed long careers in the steel and metal industries, said Queensland had an opportunity to produce its own construction materials using locally-sourced scrap metal with technology used by 25 other mills across the world.

“Local construction companies need local steel supplies to ensure security of supply, reduce reliance on imports, and make the industry more cost-effective,” he said.

“Although there is still a lot of work to do, we are confident of reaching a final investment decision in 2025, with the 18-month construction period to commence in 2026.

“This will deliver environmentally-responsible steel products here in southeast Queensland using local labour, local feedstock and global ingenuity to support the state and its growing construction industry for more than 30 years.”

GM Steel has signed a partnership deal with Wagner Corporation, which owns the land as part of its wider Wellcamp Business Park.

“This cost-effective solution that GM Steel provides is a great opportunity for Australia to boost its locally supplied demand for steel,” a Wagner Corp spokesman said.

“Wagner Corporation’s Wellcamp Business Park allows for convenient access to transport the steel in and out of the city and will ensure that GM Steel has the infrastructure needed to create a new viable industry in regional Queensland.”

Wagner Corporation director Denis Wagner was contacted for comment.

While securing finance for a project of this size will be a major hurdle for GM Steel, Mr Morgan said he believed the precedence for the technology and potential contributions from higher levels of government would help sway investors to sign on.

“Once we obtain a DA, the core elements of this project are bankable with proven technology (25 reference project globally), available feedstock, customer demand for the product, governments’ desire for sustainable manufacturing in regional Queensland and availability of key inputs like energy and water,” he said.

“We have been in discussion with the state government, which are commercial in confidence, but they are very supportive.

“The federal government has recently announced a $1 billion Green Iron Fund for exactly these types of projects as well.”

GM Steel might face competition, with WA private firm Westview Group looking to build its own steel mill worth $750m in Brisbane by 2027.