Meat the hi-tech, cost-friendly new food culture

Would you eat meat grown in a laboratory? You will soon have the opportunity, from top-end quail foie gras to mass-market lamb mince.

Australians will be eating laboratory-grown meat within months, as local manufacturers report huge demand, both from high-end restaurants and supermarkets, and regulators declare the first product safe.

Food Standards Australia and New Zealand is in the final stages of approving the first cell-cultured meat produced in Australia, but has already found the product – quail meat – is safe.

Sydney-based Vow Group – backed by investors’ $50m – is selling its lab-grown, quail foie gras and parfait-style products to wealthy Singapore diners.

Vow plans to market similar products here – via top eateries and gourmet supermarkets – as soon as FSANZ gives the final green light, expected before July.

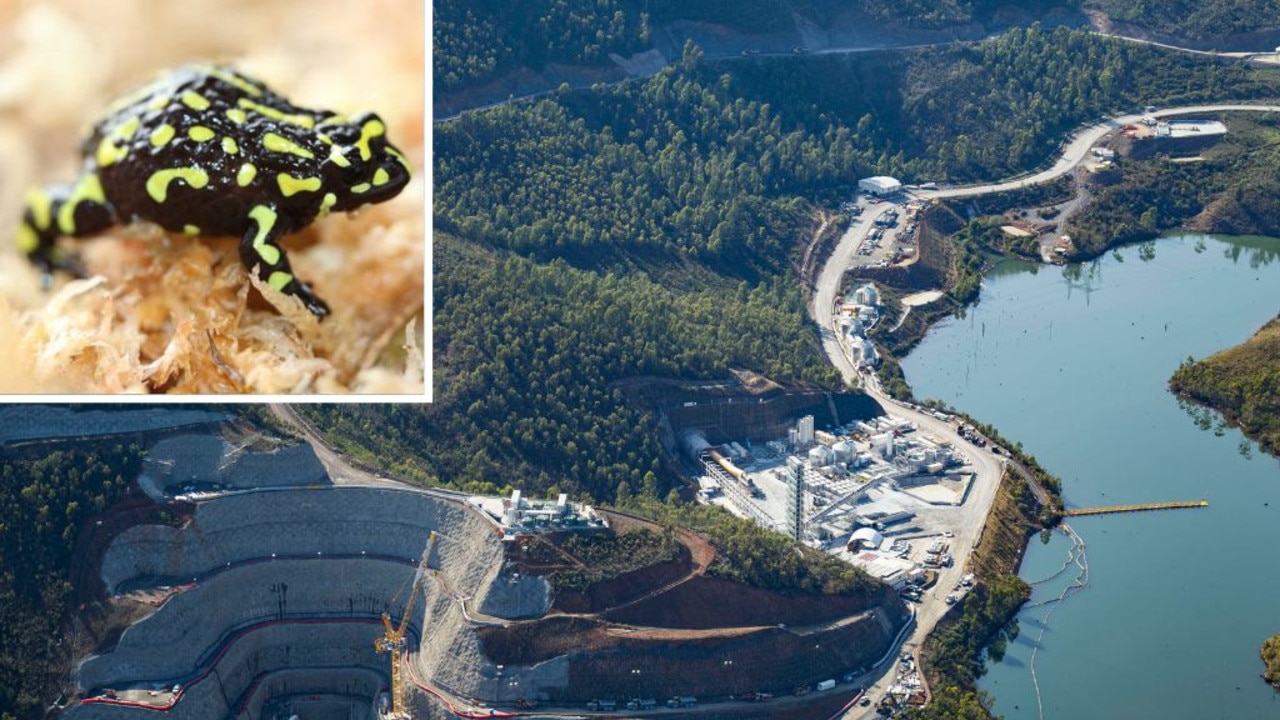

Melbourne-based Magic Valley will be next, planning for its lab-made lamb mince to be in supermarkets in 2026, at prices below those of farm-grown meat.

With the world struggling to meet demand for protein, both pioneering firms believe cell-cultured meat has a huge potential.

“This will become one of our major sources of animal protein in the coming decades,” said George Peppou, who founded Vow six years ago after working in food and agriculture innovation.

“I don’t believe it’s going to displace what we already eat. I think in 20 to 30 years you’ll walk into a supermarket and there’ll be a bunch of options made from cell culture.”

The two Australian firms believe a new generation of consumers is open to new tastes and foods, while retailers are clamouring for a product free from environmental or animal welfare baggage.

“Australia does have a bit of a conservative food culture but there is a dining scene here which is a bit more exploratory and experimental – some of our best restaurants are known for it,” said Mr Peppou, who hired cell scientists and lured engineers from SpaceX.

“We’ve found in Australia a high willingness to try, especially from younger folks.”

Vow, which made global headlines by creating woolly mammoth meatballs from ancient DNA, plans to continue to target the luxury market, before moving into “premium everyday” and eventually to mass markets.

Magic Valley is instead targeting the mass market from day one, with an initial focus on lamb and pork mince, although both firms see potential for seafood, as well.

“We’d be looking to provide mincemeat to a wholesale manufacturer who would then create a value-added product,” Magic Valley chief executive Paul Bevan said. “For example, lamb meatballs or rissoles or pork dumplings or wantons.

“We’re going for mass market distribution and the effectiveness of our technology means there’s a price point we can get down to.”

Magic Valley’s target price for its lamb mince is $6 a kilo, compared to $18 or more for the premium farm-reared product.

Mr Bevan said there was “overwhelming” interest from wholesalers and food processors. “A lot of retailers want to start selling now, driven by their internal ESG (environmental, social, governance) metrics they are looking to hit,” Mr Bevan says.

Supporters of cell-cultured meat argue it has significant environmental advantages, not requiring the grazing or slaughter of animals, the clearing and irrigation of land, or chemical use – and no methane production.

Regulatory delays were blamed for Vow recently having to cut staff, but the process should become quicker and easier, with FSANZ developing standards to be applied to future applications for product approval.

“There’s definitely a benefit in being second to market,” Mr Bevan said, adding it was hoped the cost of seeking approval for each product would come down.

“It might cost $200,000 for an application in Australia, whereas in other countries such as Singapore or the US it’s a couple of thousand dollars,” he said.

While it was possible to craft fillets and steaks, these would take longer to bring to market. “It’s easier to replicate the texture of a mincemeat product than it is of a steak or a drumstick or a fillet,” Mr Bevan said.

“That technology is there. We can do that. But in terms of doing it at scale, we’re not there yet.”

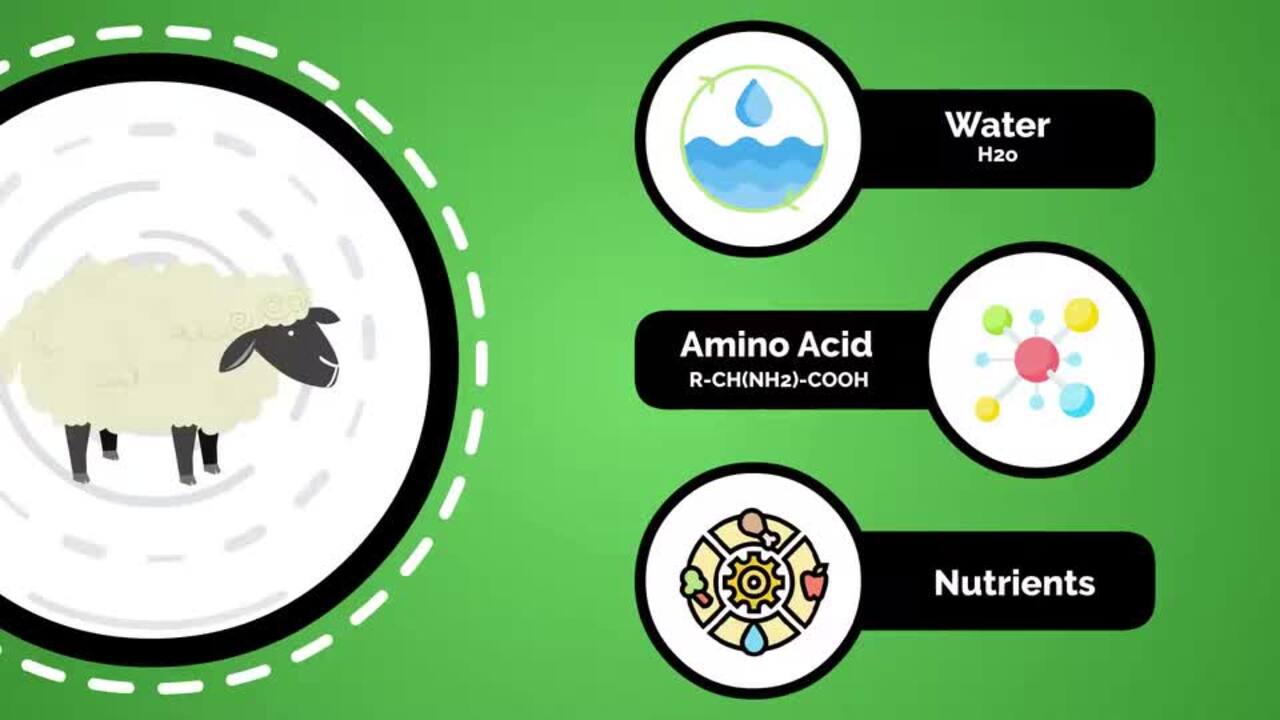

The process of making cell-cultured meat begins with cells taken from an animal. These are expanded and turned into stem cells that can be used – time and again – to create any type of meat cell, such as muscle or fat.

To produce significant quantities of meat, these cells are grown and multiplied in large fermentation tanks known as bioreactors, in a mixture of water, amino acids and other nutrients.

The cell-cultured meat can be harvested in seven days to a few weeks, depending on the meat.

Not everyone is a fan. GE Free NZ told FSANZ not enough was known about the use of growth factors and antibiotics in growing the meat cells.

However, FSANZ’s assessment found there were no antibiotic residues in the end product and no safety concerns, including related to growth factors.

Farm and meat industry groups focused submissions to FSANZ on ensuring lab-made products are labelled as such and clearly distinguishable from farm-raised meat.

FSANZ has backed the use of “cell-cultured” or “cell-cultivated” on all labels. The regulator on Friday said it would make final recommendations to relevant ministers by mid-year.

To join the conversation, please log in. Don't have an account? Register

Join the conversation, you are commenting as Logout