3D printing human organs? It suddenly doesn’t seem so far off

She lived with pain for 30 years, a bad back whittling away the pleasures of sleep, socialising, sport and sex. The ‘cure’ will amaze you.

Amanda Gorvin began to think her life had become unbearable in the early hours of a November morning last year when she found herself crawling agonisingly down the hall from her bedroom to the darkened kitchen of her home on the NSW Central Coast.

It was 2am, and Gorvin had been woken once again by a lancing bolt of pain from the deformed lower-back vertebra that had caused her more than 30 years of grief and sleepless nights. Stiffening her body against those excruciating jolts, she had lowered herself to the bedroom floor and dragged herself slowly into the kitchen, crying out as she hauled herself up to the bench, only to find she could not get to her phone.

Gorvin struggles today to describe that pain, which she’d spent her entire adult life trying to mask with anti-inflammatories, cortisone injections and physiotherapy. “It’s not like nerve pain, more like bones rubbing. You don’t move because it’s so excruciating. Everything tenses up; it’s as if your body is screaming at you to freeze.” At the kitchen bench, she downed a handful of ibuprofen pills, heedless of the dose, then stood for an hour in the dark, listening to the sounds of the night and waiting for the drugs to kick in so she could hobble back to bed. Several days later her father drove her to Prince of Wales Hospital in Sydney, where she delivered an ultimatum of sorts to her surgeon, Dr Marc Coughlan.

Seven years earlier, Coughlan had told her that surgery on her back was too risky to attempt. A spinal surgeon can often fix a faulty vertebra by wedging a titanium implant into the damaged section, along with bone-graft tissue that slowly grows around the implant and fuses the joint. But Gorvin’s dodgy lower vertebra was such a weird shape that no standard implant would fit properly; instead of being flat-topped it sloped unevenly down towards her groin, which caused the cushioning disc on top of it to slip and the butterfly-shaped joints behind to strain under the extra load. As the gap between the joints closed on the nerves passing through them, waves of pain shot into Gorvin’s back, buttocks and legs.

That pain seemed to have radiated into every corner of Gorvin’s life as the years had passed, whittling away the pleasures of sleep, socialising, sport and sex. She had gained 30kg in five years and rarely slept more than three to four hours a night; she avoided going out at night and her intimate relationships had foundered. Just pulling on her undies in the morning was a Herculean effort; anti-inflammatories got her through the day in her job as an events manager, and in the evening she collapsed in a heap. “I had always been such a positive person, so gung-ho, and I got to a point where I just felt defeated. The constant lethargy and exhaustion just debilitate your mind; more than anything you are just drained. By the time I got to see Marc, I was at my lowest point. I said to him, ‘Marc, I can’t do this anymore’. Then he said, ‘I’ve got this new thing’.”

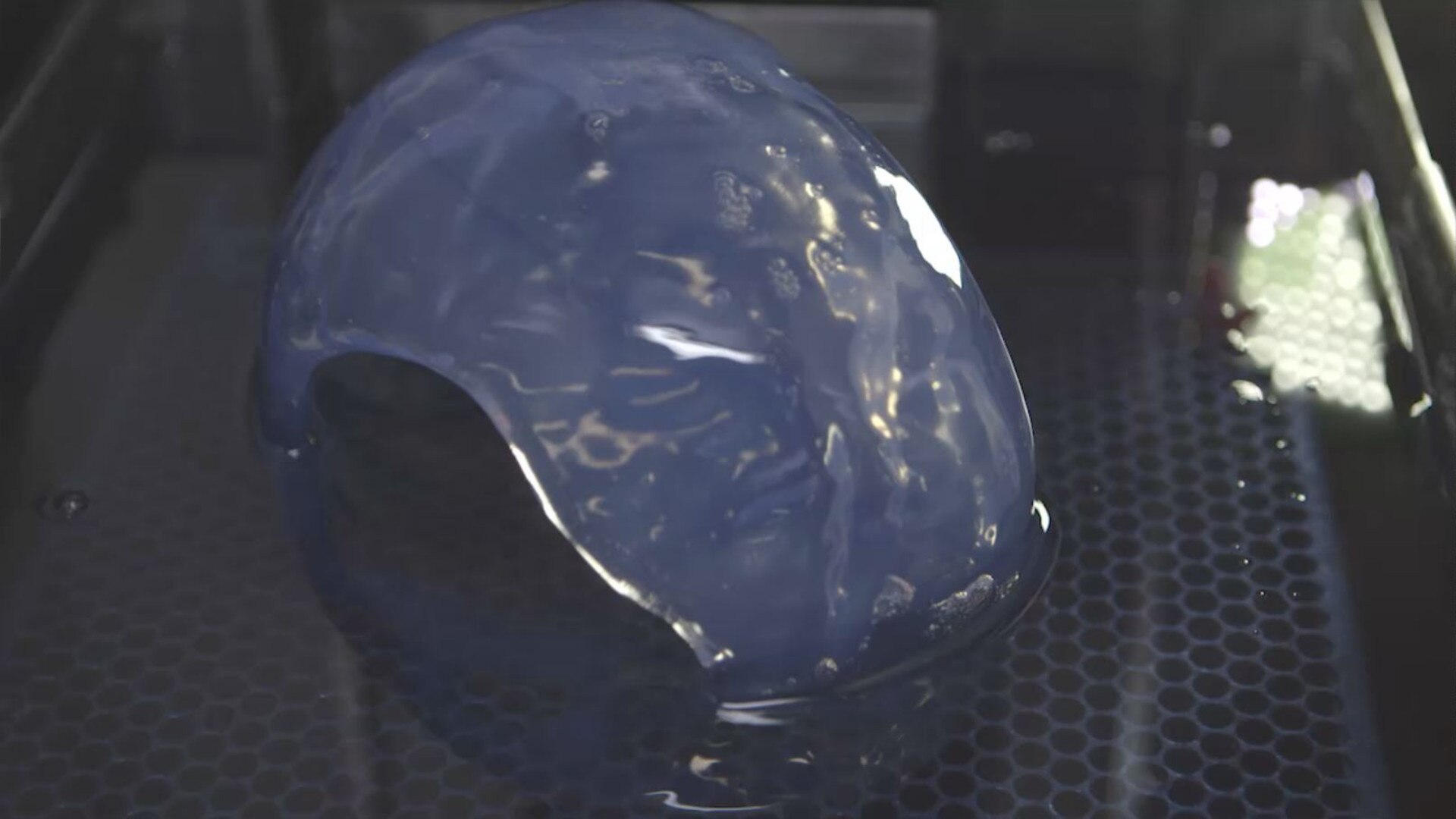

For a couple of years Coughlan had been repairing fractured skulls with plastic implants made by a Melbourne company which used 3D printers to mould the implants to the exact contours of a patient’s skull. More recently the same company, Anatomics, had started designing metal implants using a 3D printer that fires lasers into layers of powdered titanium. If Anatomics could custom-build an implant to fit snugly into Gorvin’s damaged vertebra, Coughlan explained, it might straighten her spine and alleviate her pain. The technology was so new that few surgeons in the world had attempted the procedure, and therein lay the rub: Coughlan would be the first Australian surgeon to attempt it, and Amanda Gorvin the first patient in the country to agree to it.

“Marc was honest about the risks,” she recalls. “He took me through the process; he suggested I could get a second or third opinion. But at that stage, I was ready for anything. Breakfast for me was two to three Nurofen. I said, ‘Sign me up’.”

Marc was honest about the risks. He took me through the process; he suggested I could get a second or third opinion. But at that stage, I was ready for anything.”Over several months, Coughlan and another surgeon, Chet Sutterlin, worked with Anatomics and a team of scientists and engineers at Melbourne’s RMIT University to design the implant, which in its final form resembled a misshapen donut of latticed titanium 4cm wide. One Friday in April, Gorvin was wheeled unconscious into the operating theatre at Prince of Wales Hospital, lying on her back in preparation for the procedure. Coughlan took a scalpel and cut a 10cm incision horizontally across her abdomen, and another one 12cm vertically; then he and his team parted her abdominal muscles and pushed aside her innards with forceps and clamps. Deep in there he could see the misshapen vertebra, along with something else that gave him momentary pause: it was the aorta – the body’s main artery – which passes down the front of the spine, directly in his path.

“It was only when we got to theatre that I thought, ‘Gosh, maybe we should have undersized the implant – I hope we can get it past the aorta’,” he recalls. “But we were kind of committed at that point.”

In March 2011, surgeon Anthony Atala stood onstage at a TED Conference in California and wowed a crowd of several thousand by seemingly printing a human kidney right before their eyes. Atala described how doctors can now perform CT scans on every layer of an organ such as the kidney and thus design and build a replacement organ, “printing” its cellular structure. With a flourish, he revealed a 3D printer behind him, which he said had been quietly printing a kidney even as he spoke.

The 3D printed kidney is by no means a far-fetched concept.”“It takes about seven hours to print a kidney,” said Atala, “… and we’re actually going to show you one of these kidneys that we printed a little bit earlier today.” As the surgeon donned a pair of surgical gloves, his assistant stepped forward with a petri dish and plopped into his hand a pink, gelatinous, sausage-like object. “Here it is,” said Atala. “You can actually see that kidney as it was printed earlier today.” Cue standing ovation.

In fact, Atala’s presentation was more Barnum & Bailey than Christiaan Barnard – the “kidney” in his hand was actually a facsimile, and TED was forced to correct the large number of reports that erroneously stated the organ was real. The incident has come to symbolise much of the overheated hype around 3D printing, a technology so limitless in potential that it has inspired fever-dreams from medicine to manufacturing. From China, a video emerged last year of engineers building a house using a giant 3D printer that extrudes concrete like a monstrous cake-decorator. From Spain comes Foodini, a kitchen appliance that 3D-prints food in decorative patterns. From New York comes “the world’s first ready-to-wear, completely 3D-printed” nylon bikini ($350 plus postage). Texas has given us a plastic 3D-printed pistol called the Liberator, which Australian police have test-fired and deemed to be potentially lethal – albeit not just to its target.

All these objects were created using the same basic technique of laying down a thin layer of material – plastic, concrete or food in the examples above – then solidifying it, so that successive layers can be added until the accumulation of hundreds or thousands of layers creates a three-dimensional object. Since the early 1980s, when ink-jet printers were first retooled to squirt a thin jet of plastic, 3D printing has evolved into a science of bewildering complexity. The simplest printers extrude thin strings of polymer; the most complex use lasers to transform powdered metal or liquid resin into sophisticated three-dimensional shapes. The printers themselves can be as small as a microwave oven or as big as a garage; they can print any number of materials from nylon and polymer to steel, concrete, titanium, chocolate and (yes) human cells.

Australian venture capitalist Steve Sammartino has predicted that 3D printing will outstrip the internet in its revolutionary impact, ushering in an era of “desktop manufacturing” which has massive implications for many industries. Stores such as Officeworks already print small objects to order and sell 3D printers for the home. Kiwi entrepreneur Bruce Jackson, whose firm 3D Printing Systems operates on both sides of the Tasman, tells the story of how he repaired a 10-year-old dishwasher by printing a small plastic part at home, thus saving himself hundreds of dollars (and irritating his wife, who was looking forward to a new dishwasher).

But even Jackson acknowledges that this revolution is still in its formative stages: 3D printers for home use are fairly crude machines which emit noxious fumes, and the design software that runs them takes time to master. “If you’re a hobbyist building model railways it’s fantastic,” he says. “But the hard thing for us is finding applications for the average consumer.”

The hard thing for us is finding applications for the average consumer.”For now, sophisticated and large-scale 3D printers are largely in the hands of big companies and science organisations, which have been using them for a couple of decades to manufacture objects such as plastic prototypes. As the technology has advanced into metals, it has been increasingly used to make finished components, not just models. Last year scientists at Monash University built the world’s first jet engine made entirely from 3D-printed parts, each one created in the CSIRO’s $1.3 million electron-beam printer. The printer works by directing a beam of intense heat at a thin bed of powdered titanium, melting the powder in the beam’s path; when another layer of powder is laid down, the process is repeated, and then repeated over and over, until the object – be it a piston, a turbine or a wing-nut – is completed. The powder in which it is buried is then sucked away by a vacuum.

This layer-by-layer construction means 3D printers can create intricate structures that would be impossible – or impossibly expensive – using conventional manufacturing. Spinal implants are a perfect example, because they are often made from finely filigreed titanium milled into a miniature latticework pattern that resembles the cross-hatched scaffolding of a bridge. Tiny and light, they must also be strong enough to support extreme load-bearing and porous enough for bone to grow through them. Not only can a 3D printer create complex versions of these mini-lattice structures, it can shape them in metal to fit the exact topography of a patient’s bones. The same CSIRO printer that produced the jet engine also printed a titanium heel for a 71-year-old Melbourne man, Len Chandler, who had been facing amputation of his right leg due to cancer. The heel, believed to be the first implant of its kind in the world, was designed in only two weeks by Anatomics, the Melbourne firm that would later make Amanda Gorvin’s spinal implant.

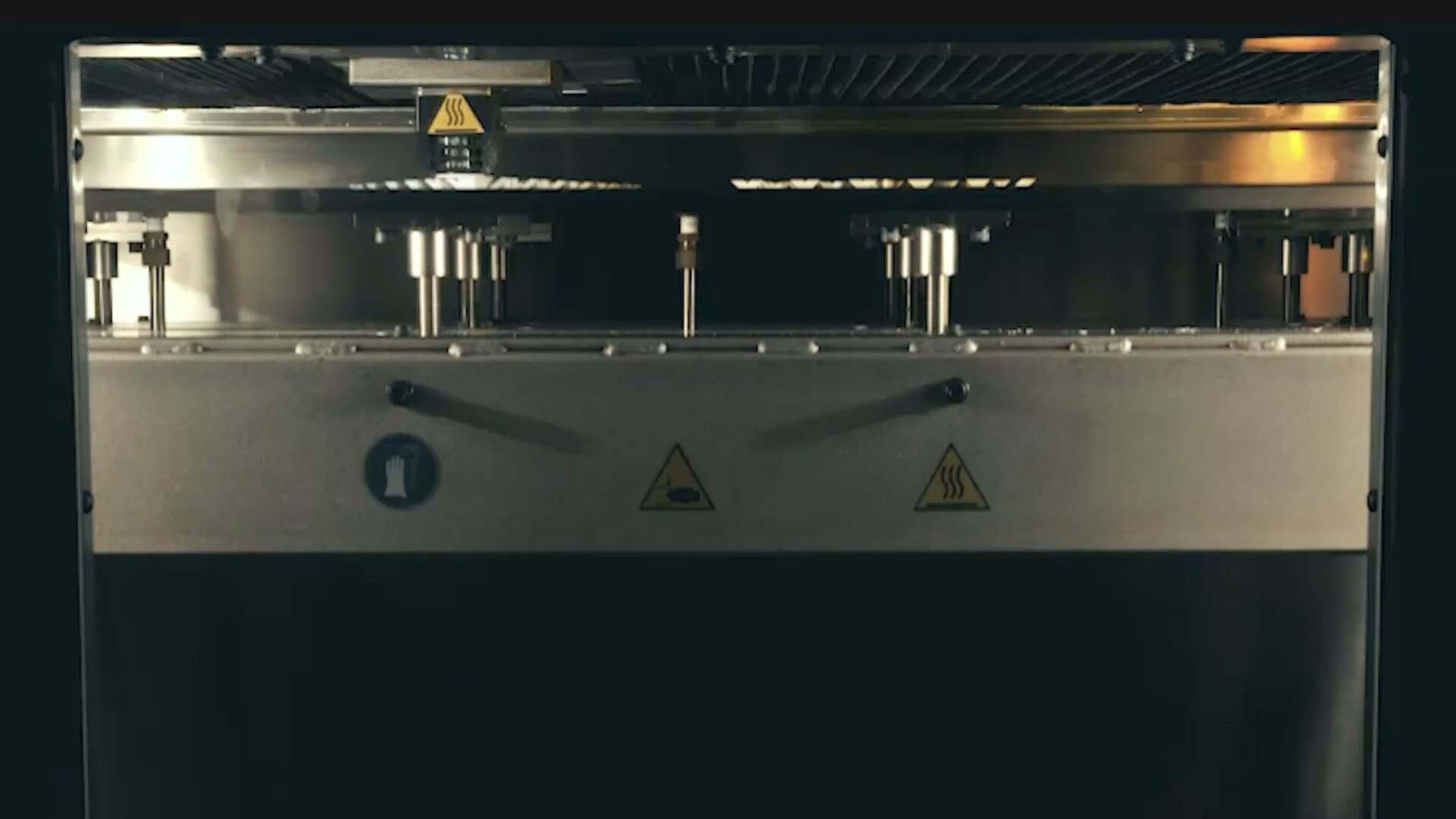

Anatomics was founded by Queensland neurosurgeon Paul D’Urso in 1998 and today operates out of the ground floor of an office building in St Kilda. Step beyond the company’s unprepossessing lobby and you find yourself in an office/laboratory where medicine’s technological future is already taking shape. Here computer servers operate 24 hours a day receiving orders for human body implants from surgeons around the world. Radiographers, biomedical technicians, orthotists and cranio-facial technicians sit at computer terminals scrutinising three-dimensional CT images of fractured skulls, cracked eye-sockets and weak chins that require aesthetic improvement. A row of 3D printers methodically spits out polymer models of human body parts and prosthetics, while inside an airlocked laboratory, technicians craft surgical implants from a patented polymer the company has brand-named PoreStar.

A growing proportion of Anatomics’ business is cosmetic surgery implants, a particularly booming market in Asia. “Here’s someone who wants a bigger chin,” remarks chief executive Andrew Batty as he peers at a computer image of a human jaw being worked on by one of his staff. “With the new design technology that’s available, and porous polymers like PoreStar, it really is possible these days for people to correct facial asymmetries and redesign their own face.”

Shaven-headed and fit-looking, Batty has a science degree, a masters in business and a good ear for laconic one-liners. “With 3D printing,” he says, “we can turn around implants in five to 15 days, particularly for cosmetic surgery or routine holes in the head.” But he is cautious about the hype around 3D printing in medicine as more companies line up to cash in on the boom for customised body parts. Anatomics works closely with the CSIRO and RMIT University, and has earned accreditation with the International Organisation for Standardization (ISO) as a maker of medical devices, but in Australia any company can manufacture a “custom” medical device for one patient only without seeking approval from the Therapeutic Goods Administration. Such devices must meet minimum standards, but the TGA will ask for proof only if they undertake an audit. It’s a provision designed to allow for minor variations to medical devices, but one that will surely need stringent policing as 3D printing becomes cheaper and more widespread.

With 3D printing we can turn around implants in five to 15 days, particularly for cosmetic surgery or routine holes in the head.”“It’s going to revolutionise manufacturing but there’s going to be a lot of mistakes made,” remarks Chet Sutterlin, a veteran US spinal surgeon who came to Australia in 2011 to take up a training job and ended up staying here. Still, he believes Australia’s relatively benign regulatory environment means we are uniquely placed to capitalise on the boom in “patient-specific implants”, as they’re more technically called. Not long after arriving here he established an organisation to research custom-implants and gather data on their effectiveness. That was how he came across Amanda Gorvin and her diabolical spine.

“I had been asking surgeons if they had a case that would be amenable to a 3D-printed solution, something unique that couldn’t be treated with an off-the-shelf implant,” says Sutterlin. “Marc Coughlan said he had a patient that he really wasn’t sure how to treat. When he showed me the CT scans I said, ‘OK, we’re ready to do it’.”

The human spine is a devilishly complicated sequence of bones and joints; the misalignment of one vertebra can set off a cascade of problems up and down the line. Coughlan had been reluctant to operate on Gorvin for precisely that reason. “Putting a conventional titanium implant in Amanda’s spine would have been like putting a rectangle into a triangular space,” he says. “And if you removed the entire vertebra, you’d have to replace it with a massive strut which can cause a domino-effect of alignment problems up the spine.”

Although surgeons in China and France had reportedly used 3D-printed implants in recent spinal operations, no peer-reviewed literature on those operations existed. So Coughlan and Sutterlin sketched their vision of a spinal implant and went to Anatomics, which in turn enlisted RMIT University’s Advanced Manufacturing Centre, which was not only equipped with a titanium 3D printer but also boasted a team of scientists who were expert at transforming finely filigreed titanium into “mathematically complex topologies”. Over several months the design for Gorvin’s spinal implant was refined by being cast and re-cast in 3D-printed plastic and metal until it appeared perfect.

Gorvin recalls the morning of the operation clearly. “I was frightened out of my mind. The thought of going under the knife was something I had always put off: one slip and you’re in a wheelchair for the rest of your life. Those were thoughts that had gone through my head.”

Coughlan, who’d trained at the same Cape Town hospital where Christiaan Barnard performed the first human heart transplant in 1967, had a few hidden anxieties of his own. He had felt compelled to help Gorvin after seeing her emotional distress, and he was sure this implant offered her best shot at recovery, but he was also stepping into the unknown. “If someone comes to you with a terminal illness, it’s easy to justify trying something new,” he says. “When you’re dealing with a perfectly healthy young woman who happens to be in terrible pain, it can be harder to explain if you make a hole in her aorta.”

The beautiful thing when we put the implant in was that it felt like a key going into a lock; I could actually feel it click into place.”So it was that on the morning of April 3, Coughlan watched his vascular surgeon take a soft-tissue retractor and push Gorvin’s aorta as far to one side as he could, exposing the gnarly spinal bone that had made her life so difficult. The custom implant lay on a nearby tray, along with an off-the-shelf model the surgeon had ordered as a fall-back, a compromise he dearly hoped to avoid. With a scalpel he painstakingly cut away the pulpy disc above the faulty vertebra and then cleaned the area around it. Then he picked up the implant in a pair of blunt forceps, inserted it gingerly into the wedge-shaped gap it was designed to fill, and pushed down. “The beautiful thing when we put the implant in,” he recalls, “was that it felt like a key going into a lock; I could actually feel it click into place. It was so intrinsically stable, it was like a dream for a spinal surgeon.”

Gorvin made her first attempt at standing 72 hours later in her ward, with physiotherapists and nurses holding her as she rolled off her bed, onto her feet, and straight into a bottomless ocean of pain. “It was crazily painful; it felt like your ribs and your spine about two-thirds of the way down were collapsing in on themselves. I’m standing up straight for the first time in nearly 40 years and it was like the nerves and the muscles and spine were all hypersensitive from trying to cope with bearing the weight.” Gorvin had actually undergone two operations – one to insert the implant and brace it in place, another on the back of her spine to fit a supporting brace there. She was on so many painkillers she began seeing unicorns. But by Day 4 she had walked to the door on a frame, and by Day 10 she was getting around in her clothes.

On April 15 she walked out of hospital, very slowly, and was driven home.

Inside the laboratories of the Intelligent Polymer Research Institute at Wollongong University, surrounded by machines like the 3D-Bioplotter and Nano-Yarn Spinner, Professor Gordon Wallace and his team are inching towards medicine’s holy grail: manufacturing human flesh and bone on a 3D printer. That might seem redolent of Frankenstein and the Terminator films were it not for the bespectacled prof’s melodious Irish accent and leprechaun-like chin-tuft, which somehow lend a tone of merriment to the scientific futurism he presides over.

Three years ago, Wallace and his team worked out a way to infuse human stem cells into liquid and pass it through a printer nozzle without the cells losing their viability or structure. Next year they hope to begin “printing” sections of nerve and cartilage cells and transplanting them into animals to test their viability. The 3D-printed kidney is, it turns out, by no means a far-fetched concept.

Ultimately I can see a range of printers being involved: a cartilage printer, a muscle printer, a nerve printer…”“The complete artificial organ I’m sure will be done,” Wallace says, adding that custom-made human tissue is likely to become intrinsic to medicine. “Ultimately I can see a range of printers being involved: a cartilage printer, a muscle printer, a nerve printer…” Researchers here are already developing a hand-held “bio-pen” that squirts cells into a targeted area of the body like an inkjet, an accessory Wallace jokingly imagines surgeons ordering in gold-plated monogrammed editions. The metal components of the bio-pen are themselves built and refined using 3D printing. (“Yes, we’re using 3D printers to make 3D printers,” quips one researcher. “It gets a bit meta.”)

The Intelligent Polymer Research Institute is one of dozens of labs around the world exploring the extraordinary possibilities unlocked by this technology. Burns researchers are already experimenting with printing skin cells directly onto injuries, while the French cosmetics giant L’Oreal is planning to manufacture skin for use in testing its perfumes. Even if the first 3D printed organ is years away, Wallace notes, the technology is already making it possible to carry out three-dimensional biological experiments on stem cells, nerve cells, bones and cartilage. What’s unclear is how it will be regulated.

“This is a really big breakthrough, not just a step forward; it potentially changes how you deal with fundamental issues in medicine,” Wallace says. “Is the surgeon going to have a printer in the surgery? Is that regulated? Does that mean it’s just part of the surgical procedure – it’s not treated as a drug? A lot of this just can’t be captured by today’s regulatory framework.”

Just how rapidly things are moving was shown in June when a Melbourne company, 3D Medical, announced it had developed Australia’s first 3D-printed titanium jaw implant designed to realign the face of a 32-year-old Melbourne man, Richard Stratton. 3D Medical’s chairman, Dr Nigel Finch, says the company will produce another 25 of the implants by June next year. But Finch is not a medical doctor – he has a PhD in business law – and 3D Medical does not yet have ISO accreditation to make medical devices.

The jaw implant – which is designed to replace the temporomandibular joint (TMJ) – was invented by a Melbourne maxillofacial surgeon, Dr George Dimitroulis, and developed with scientists at the University of Melbourne and the company Signature Orthopaedics. Dimitroulis has formed a company, TMJ Solutions, to sell it commercially, and hired 3D Medical as the manufacturer. But the first implant was actually printed in New Zealand because 3D Medical’s titanium printer is not yet calibrated. According to Finch, 3D Medical helped design the implant, and also played a role in “gaining necessary approvals with hospitals, clinicians, healthcare suppliers and the health insurer”.

Jaw implants are notoriously prone to malfunction; the US Food and Drug Administration has reported that substantial numbers of patients report extreme pain from TMJ implants, and it allows only two companies to make them. But Dimitroulis says his first operation was a success and he is hoping his company can become “the third player” in the market. “Hopefully with a bit more cash from investors we may have a fledgling new Australian medical device company,” he says. Meanwhile he is already working on a new 3D-printed surgical implant which he says he will announce soon. “So watch this space!” he says cheerfully.

On her most recent visit to Marc Coughlan’s consulting rooms at Prince of Wales Hospital, Amanda Gorvin walked in wearing high heels for the first time the surgeon could remember. The heels had come back on a month earlier, as Gorvin regained confidence in balancing her newly straightened spine atop 5cm stilettos. More recently she had started a morning regime of one-hour walks, and had stopped taking painkillers for the residual nerve pain that sometimes flared in her legs but now seemed to be subsiding.

It’s nothing short of miraculous. This has absolutely changed my life.”“I was back at work four weeks after the operation, back in the gym after six weeks,” she says. “I was breathing better, my mind was clearer, I felt lighter. It’s incredible how much influence the spine has on the rest of the body. I remember that pre-surgical pain and now I haven’t got one per cent of it. It’s nothing short of miraculous.” As she speaks, Gorvin becomes emotional and reaches for a tissue. “This has absolutely changed my life,” she says.

For Coughlan, it’s an outcome beyond his expectations and a pointer to where medicine is headed. “The last time I saw Amanda before surgery, she was pretty stressed and quite desperate. As a doctor, you try to factor in the physical and the emotional coping mechanisms of your patient. Maybe this is the way medicine can go, customised more to the patient’s needs.”

Gorvin has a few projects on her to-do list, including shedding some of the kilos she acquired in recent years due to lack of physical activity. For now she’s experiencing the sheer joy of normal life. Recently she took on a weekend events-managing job at a surf club. After setting up 180 chairs and fitting each of them with a seat cover, she climbed a ladder to hang fairy lights and a disco ball. She spent the night supervising the kitchen and bar staff, and when the work had finished, she joined the revellers on the dancefloor. In her high heels.

Videos supplied by Anatomics