Fortescue axes leaders as Iron Bridge project blows out

Fortescue Metals has rung the changes in its senior leadership team as it struggles to get costs at its Iron Bridge magnetite operation back on track.

Fortescue Metals has rung the changes in its senior leadership team as the company struggles to get costs at its Iron Bridge magnetite operation back on track amid cost blowouts that could top $US650m ($840m).

It is understood director of projects Don Hyma has parted ways with Fortescue after only two years with the company, along with the Iron Bridge project manager, as Fortescue rejigs its management of the massive project.

The Australian revealed in January that Iron Bridge was facing cost blowouts that could top 25 per cent of its original $US2.6bn budget, and Fortescue’s board is set to consider new estimates of the total cost and time frame for the mine and processing plant ahead of its half-year financial results, due on Thursday.

It is understood Mr Hyma left Fortescue last week, along with key members of the project’s team, with the company likely to announce a restructure of the Iron Bridge leadership early this week.

Fortescue is also mulling financing options for the project, having previously said any borrowings would be secured against the project itself, without recourse to Fortescue’s balance sheet.

Fortescue chief executive Elizabeth Gaines confirmed last month that costs and scheduling for Iron Bridge were “undergoing a detailed review” as the company finalised engineering work, with the strength of the Australian dollar adding to rising operational costs in Western Australia. Competition for skilled workers amid border lockdowns was also making it more difficult to source construction workers from interstate.

Similar pressures forced a $US100m blowout in the budget of Fortescue’s new Eliwana mine, which shipped its first ore in December, as Fortescue raced to get the $US1.375bn project into production on its original schedule.

Iron Bridge includes an ore processing facility capable of producing 22 million tonnes of concentrate a year, an airstrip and accommodation camp, a 135km pipeline to Port Hedland to pump magnetite slurry to the port and return water to the mine, as well as another 195km pipeline to source water from borefields in the Canning Basin.

Fortescue originally planned to ship the first ore from Iron Bridge by mid-2022, with the mine designed to deliver 22 million tonnes when it is fully ramped up.

The mine is a key element of Fortescue’s plan to move its iron ore up the value chain by producing higher grade ore and moving its average shipment grade above 60 per cent iron.

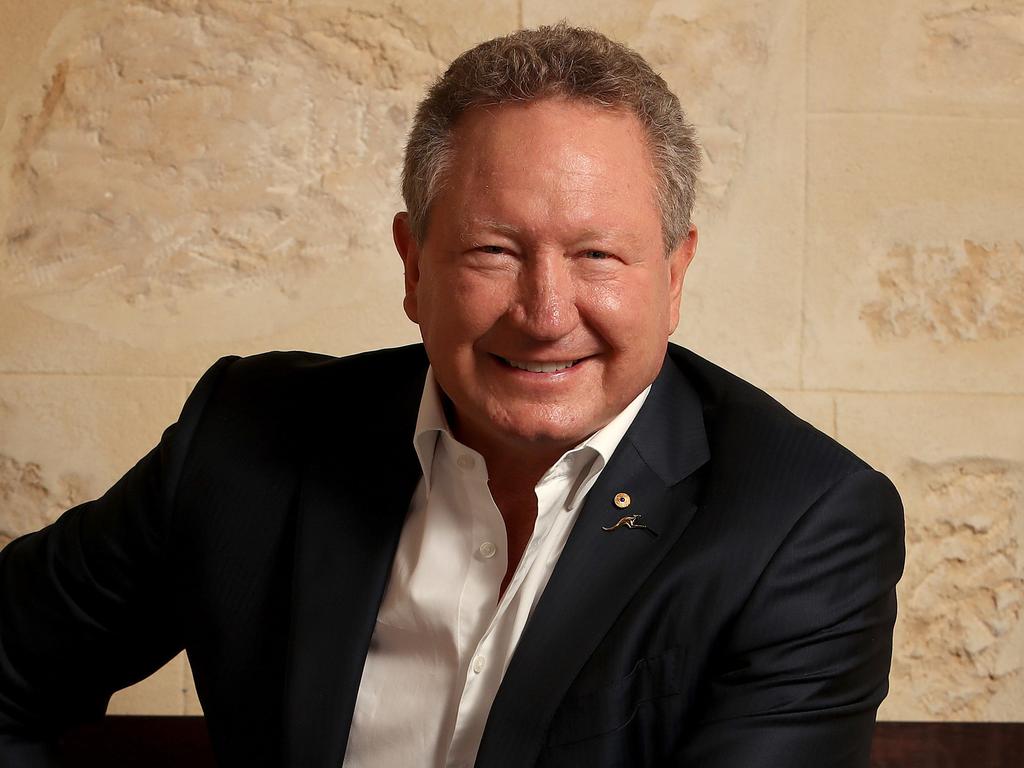

It could also eventually provide a feed for the “green steel” plan unveiled for Fortescue by chairman Andrew Forrest in January, with the company planning to build a pilot plant in WA by the end of 2021, and a commercial plant within a few years.

When launching the project Fortescue said it expected Iron Bridge to grade 67 per cent iron, with lower impurities than ore produced from mines in Brazil and Australia, and sell for a premium to benchmark prices.

It tipped the mine would have production costs of about $US45-$US55 per tonne, with capital of $US4-$US6 per tonne, and costs for royalties, administration and shipping.

Taiwan’s Formosa Plastics owns a 31 per cent stake in Iron Bridge, and the Fortescue subsidiary that controls the project is 12 per cent-owned by China’s Baowu.

To join the conversation, please log in. Don't have an account? Register

Join the conversation, you are commenting as Logout