Navy in world first Darwin 3D tech trial

Revolutionary technology developed at Charles Darwin University will be used by the Royal Australian Navy in a world-first trial that will streamline the maintenance of the nation’s patrol vessels.

Business

Don't miss out on the headlines from Business. Followed categories will be added to My News.

Revolutionary technology developed at Charles Darwin University will be used by the Royal Australian Navy in a world-first trial that will streamline the maintenance of the nation’s patrol vessels.

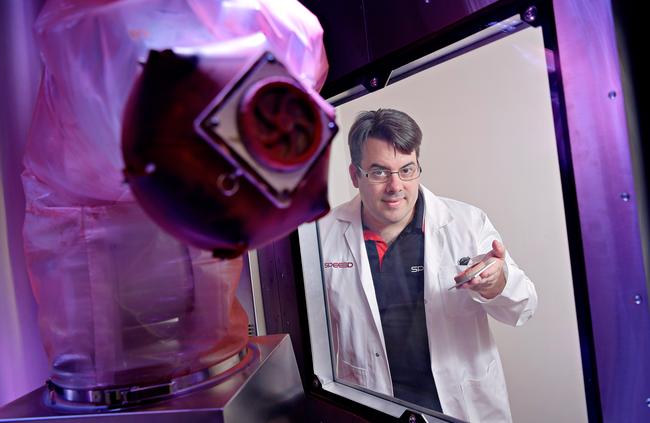

The Morrison Government will announce a $1.5 million deal today that will thrust the CDU’s LightSPEE3D printer technology to the forefront of the world Defence maintenance sector.

The $1.5 million investment will see a two-year Supersonic Deposition 3D printer pilot in Darwin that will lead to a significant increase in the availability of parts, outpacing regular supply chains.

Federal Defence Minister Minister Melissa Price has flown into Darwin today to confirm the $1.5m world trial today.

She said the Charles Darwin University’s Advanced Manufacturing Alliance (AMA) and industry partner SPEE3D technology has a uniquely Australian capability.

She said it is prime example of Australian innovation at its best.

“This hi-tech machinery enables cold metal components to be produced quickly

and efficiently, meaning our ships can get back on the water without delay,” Minister

Price said.

“Benefiting both the Australian Navy and industry, the knowledge transfer gained using this

capability also positions the Advanced Manufacturing Alliance to pursue further

opportunities.

“This capability supports the Government’s unprecedented shipbuilding and sustainment plans.”

Director of the CDU-based AMA, Dr Rebecca Murray describes the SPEE3D manufacturing technology as a great fit with Defence.

“Often parts are needed quickly to meet operational demands, new designs need to be manufactured for testing and a supply of legacy parts is often still needed,” she says.

“The strength of the manufacturing process with this new technology is that it can be operated nearly anywhere, can shorten design cycles and produce parts quickly as one-offs or small batches for testing. The traditional casting manufacturing systems can’t offer these attributes.”

Minister Price will also inspect work underway as part of the $1.1 billion defence infrastructure upgrades in the Top End.

Lendlease Building, the managing contractor for the $1.1 billion works, is asking Territory contractors, subcontractors and suppliers to attend key information nights for RAAF base Tindal stage 6 redevelopment and RAAF base Tindal US Force Posture Initiatives airfield work.

The Darwin session will be November 27 at the DoubleTree by Hilton Esplanade from 4pm and the Katherine session will be at the Katherine Town Council on November 28 from 4pm.

At the sessions, Lendlease will present an overview of the project scope and outline the procurement processes.