Revealed: Global giant Caesarstone knew of silicosis threat to Gold Coast and Queensland stonemasons

There are terrifying numbers of young workers being put at risk - and the scary part is how much the industry knew. READ THE CHILLING REPORT

Gold Coast

Don't miss out on the headlines from Gold Coast. Followed categories will be added to My News.

AN international supplier of toxic engineered stone knew of the potential fatal risks it presented to stonecutters at least 17 years ago, but continued to sell it.

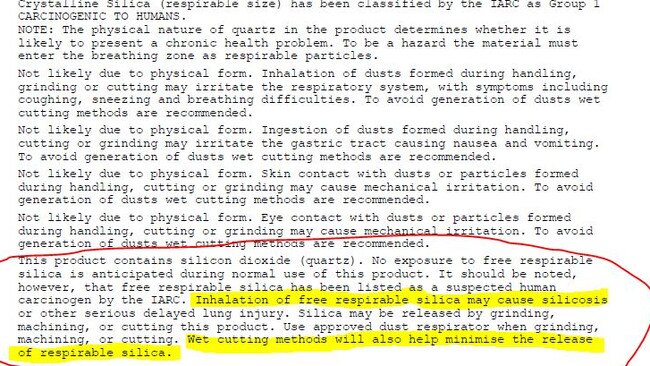

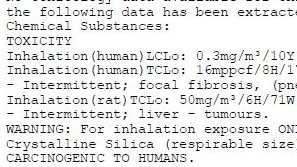

A 2003 material safety data sheet obtained by the Bulletin shows stone giant Caesarstone warned that stonemasons should never have been allowed to grind, machine or cut the stone using dry methods.

The toxicology report states that the respirable crystalline silica (RCS) contained in the product had been listed as a suspected human carcinogen by the International Agency for Research on Cancer.

“Inhalation of free respirable silica may cause silicosis or other serious delayed lung injury,” the data sheet reads. “Silica may be released by grinding, machining or cutting this product.”

PART ONE: GOLD COAST DYING OF SILICOSIS WANTS ENGINEERED STONE

It recommended using an approved dust respirator when cutting Caesarstone.

“Wet-cutting methods will also help minimise the release of respirable silica.”

Despite the written disclaimer nearly two decades ago, thousands of stonemasons across Queensland and Australia have been covered in silica dust like “snowmen” without any safety equipment.

A Bulletin investigation this month revealed 174 Queensland stonemasons have been diagnosed with silicosis in less than two years. Thirty-two are expected to die from progressive massive fibrosis.

A whistleblower told the Bulletin the stone industry was “aware of the problems of man-made imitations and had heated debates on it”.

“I worked in the stone industry for many years, marketing internationally and then I opened my own stone benchtop company using real granite,” he said.

PART 2: STONEMASONS WITH SILICOSIS THROWN TO SCRAP HEAP

“I hated the fake man-made stuff and was at continual loggerheads with them (importers of engineered stone).

“They kept telling the public they improved what God had made and took the imperfections out of real granite. They made billions of dollars out of it and should have to pay for their lies.

“It’s there as plain as day in the safety data sheet. It (engineered stone) is as bad as it gets.”

Caesarstone, whose total revenue in 2016 was US$538.54 million, has production facilities in Israel and the USA.

Caesarstone Australia told the Bulletin that it had and continued to “actively promote and educate on safe handling of our products by stonemasons to protect against the risks of silica dust exposure”.

“In the 12 years since Caesarstone Australia began direct operations in Australia, we have provided the independent stonemason industry information about the safety measures required to be implemented when working in a silica dust environment including,” the statement read.

PART THREE: INSPECTORS TO AUDIT A ‘SAMPLE’ OF 140 WORKPLACES

“Caesarstone supplies each individual slab to stonemasons with the relevant warnings, health and safety information prior to fabrication and installation.”

It said the surfaces were “completely safe in their manufactured state and when installed in any environment” but that it welcomed ongoing audits of stonemason workshops to ensure compliance to safety standards.

SILICOSIS SCANDAL SERIES

PART 1: Gold Coast dad dying of silicosis wants engineered stone banned in Australia

PART 2: Shocking reason Gold Coast stonemasons refuse health checks

“Caesarstone’s own recommended safety standards have long urged stonemasons to use wet-cutting and proper respiratory protection.”

In 2017-18, inspectors from Workplace Health and Safety Queensland audited the stone benchtop industry and initially found “widespread noncompliance with WHS laws within the industry”.

Both employers and workers had a poor understanding of the risks of respirable crystalline silica and uncontrolled dry-cutting was commonplace up until the past one-five years.

Recently, in response to questions filed by the Bulletin, the Office of Industrial Relations said a “sample” of 140 workplaces would be re-audited to see if they were complying with the code.

USEFUL FACT SHEET ABOUT SILICOSIS

But it’s too little too late for thousands of stonemasons such as Gold Coast father of six Adam Emery, who has the most aggressive form of silicosis. Before he dies he wants the importation of engineered stone banned in Australia.

Last year, Industrial Relations Minister Grace Grace requested that the Australian Competition and Consumer Commission investigate the matter of imported engineered stone and the related silicosis risks.

As a result the Federal Government set up the National Dust Disease Taskforce to investigate those at risk in the industry. The taskforce has flagged five interim recommendations and 17 findings, including examining if the importation of engineered stone products should be banned in Australia. A final report is due by mid-2021.

MORE NEWS

THE GOLD COAST PLAYGROUND COUNCIL SAYS IS SAFE BUT PARENTS DONT

KIWI JOINS POLITICAL PARTY TO FIGHT FOR A PATHWAY TO CITIZENSHIP

HOW THE STORY EVOLVED

INSPECTORS from Workplace Health and Safety Queensland are finally re-auditing the stone benchtop industry.

The Bulletin filed questions as part of its investigation after it learnt the Queensland Government presented a submission last November stating phase 3 of an Office of Industrial Relations (OIR) audit would happen in May.

In its response this month, the OIR said a “sample” of 140 workplaces would now be checked to ensure they were complying with the Code of Practice 2019.

Under the code, the workplace exposure standard for respirable crystalline silica that must not be exceeded is 0.05 mg/m3 (eight-hour time weighted average). Business owners are responsible for ensuring workers undergo the proper health checks.

But CFMEU boss Royce Kupsch fears that without a “strong cop on the beat”, Gold Coast stonemasons will continue to die from silicosis.

“If workplaces strictly adhere to this then workers won’t be exposed to dangerous levels of silica dust. But without a strong cop on the beat, I’ve got no confidence every workplace or business will adhere to it,” he said.

“Across Queensland there are nearly 150 workplaces that employ anywhere from five to 60 stonemasons and unless the Government puts more people on to check each and everyone, then there’s no way to ensure everyone is doing the right thing by their staff.”

WHY DUST DISEASE VICTIMS SHOULDN’T HAVE TO FIGHT FOR COMPO

A submission to the National Dust Disease Taskforce (NDDT) shows that between October 2017-July 2018 the OIR undertook phase 1 compliance audits on 10 stone benchtop fabrication businesses in southeast Queensland. It found “widespread noncompliance with WHS laws within the industry”.

Employers and workers had a “poor understanding of the risks of respirable crystalline silica” and that uncontrolled dry-cutting was commonplace up until the past one-five years.

Businesses were also making alternations during the installation of benchtops using dry-cutting methods, and there was a misconception among the majority of workers that respiratory protection and health monitoring wasn’t needed during wet processing of engineered stone.

GOLD COAST STONEMASON ANTHONY WHITE DIES FROM SILICOSIS AT 36

In September 2018, phase 2 audits were conducted at 138 workplaces, providing “stronger evidence of wide‐spread non‐compliance”. Dry-cutting was immediately banned in Queensland at this time and nearly 600 statutory notices were issued for respirable crystalline silica related contraventions. This included:

• 57 prohibition notices, including for uncontrolled dry-cutting of engineered stone and inadequate workplace cleaning practices; and

• 541 improvement notices for not providing health monitoring, inadequate dust

control, and issues with use and fit testing of respiratory protective equipment.

As at 22 October 2019, 17 infringement notices had been issued with fines totally $58,000.

Mr Kupsch said engineered stone accounted for up to 70 per cent of product manufactured on the Gold Coast, it was preferred by architects and that it was “cheap and available in any colour”.

He said suppliers of engineered stone were adamant the product did not pose any threat to workers if it was handled correctly and they adhered to strict safety protocols.

“The onus is on employers to take responsibility for the health of their workers but in some instances I know people will get the punt if they ask for a health screening for silicosis,” he said.

“I don’t think we’ve seen the true spike in people presenting with silicosis because they don’t want to make contact with their doctor for fear they’ll lose their jobs.”

WHAT IS THE QUEENSLAND GOVERNMENT DOING ABOUT THE SILICOSIS CRISIS?

According to spokesman from the Office of Industrial Relations (OIR), Queensland is leading the nation in its response to responding and addressing silicosis in the engineered stone industry.

In the absence of a co-ordinated national approach to occupational dust, the State Government agency says it is engaged with suppliers and importers of engineered stone products to ensure they understand the risks associated with respirable crystalline silica.

They also have to give details of information provided to every person they’ve supplied with engineered stone.

Last year, Industrial Relations Minister Grace Grace requested that the Australian Competition and Consumer Commission (ACCC) investigate the matter of imported engineered stone and the related silicosis risks. She also advocated for “national action in response to the threat posed by respirable crystalline silica, including the development of a national code of practice”.

But the State Government has fallen short of calling for a ban on the importation of engineered stone, saying “border control and the banning of imports is a matter for the Federal Government”.

The OIR spokesman said other actions taken by Queensland include:

• An industry-wide audit campaign of known stone benchtop fabrication businesses.

• Development of a nation-first code of practice.

• Implemented an agreed reduction to the national workplace exposure standard for RCS from 0.1 milligrams per cubic metre (mg/m3) to 0.05mg/m3 with the expectation of a further reduction.

• Free initial health screenings for current or former workers exposed to dust from engineered stone at workplaces.

• WorkCover assistance with the workers’ compensation process, medical treatment and rehabilitation.

• Removal of two-year time period from the definition of “terminal condition” in the Workers’ Compensation and Rehabilitation Act 2003 so workers given a life expectancy of greater than two years can get terminal benefits (lump sum of up to $714,455).

• Commissioning of an international research project to examining support for workers diagnosed with silicosis.

• Established Australia’s first Notifiable Dust Lung Disease Register.

• Created legislative reforms and standards relating to monitoring and control of RCS for mine workers.

• Set up the Mine Dust Health Support Service.

• Started work on new code of practice for the management of RCS in construction industry

WorkCover’s website has a range of resources for stonemasonry workers and employers or call 1300 362 128 to arrange a health screen or worker’s compensation claim.

MONDAY IS D-DAY FOR SECOND WAVE OF COVID-19

SILICOSIS FACTS

* Silicosis is an occupational lung disease caused by inhalation of crystalline silica dust and is marked by inflammation and scarring in the form of nodular lesions in the upper lobes of

the lungs.

* Silicosis cannot be cured or treated, and it’s often fatal with thousands of stonemasons thought to be at-risk of this deadly disease.

* As of July 31, 2020 WorkCover had completed health screening of 1052 stonemasons exposed to respirable crystalline silica from engineered stone.

* 217 were diagnosed with a work-related condition.

* Of these workers 174 have silicosis, 32 had progressive massive fibrosis (potentially fatal) and 13 have respiratory condition that is not silicosis.

Rock and rock products contain different amounts of silica

• Demolition Dust 3-4%

• Shale 22%

• Clay bricks 15–27%

• Aggregates in concrete 30%

• Fibre cement bricks 10–30%

• Granite 25-40%

• Natural sandstone 67%

• Engineered or manufactured stone 90-95%

What can silica dust do?

When silica dust lies within the lung tissues, chemical reactions can occur which result in tissue injury followed by the healing response of the lung. Dust lodged in the lungs can cause an inflammatory process, scarring in the lungs and reducing the body’s ability to breathe in oxygen and breathe out carbon dioxide. Damage in the lung tissue causes a small scar, in the form of a small nodule which can be seen on a chest x-ray. This type of lung damage is called silicosis.

Symptoms of simple silicosis

There may be no symptoms.

Shortness of breath.

Chest pain.

A cough.

Symptoms of complicated silicosis

Shortness of breath.

Chest pain.

Chronic cough.

Increased sputum.

Lung dysfunction.

Pulmonary hypertension.

Heart complications.

Visit here for useful information and resources on silicosis