Family-owned engineering firm Birdon gambles on army vessel prototype to plug capability gap

In an Australian first, a family-owned business is building a fully operational prototype army assault vessel before any tender is awarded. See why.

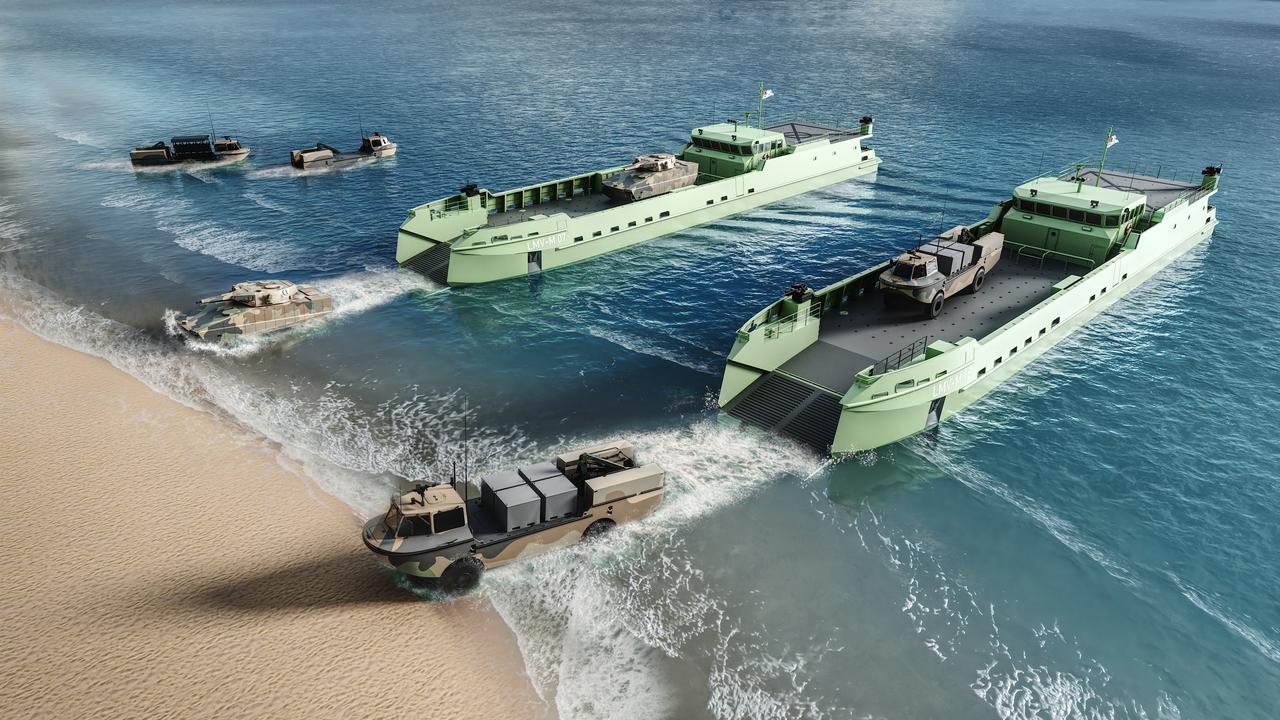

Exclusive: A full-scale 50-metre long amphibious army vessel for rapid deployment of tanks and troops is being quietly built in an ambitious multimillion-dollar proof-of-concept gamble.

The new capability is designed to transform how the Australian Army can operate long-range around Northern Australia and the Pacific region, whether for humanitarian assistance or in a high-threat scenario.

As proposed under Defence’s Force Structure Plan, the $800 million acquisition of 18 new bigger, faster and more versatile landing craft was deemed urgent in order to replace the 1970s Vietnam War-era fleet currently in service.

But in what is believed to be an Australian first for a military procurement of its type, family-owned maritime engineering and defence contractor Birdon is building a full-scale prototype before the contract is awarded to any bidder.

There are believed to be four consortium industry groups pitching for the contract.

The self-funded initiative for the new class of medium-sized Littoral Manoeuvre Vessel (LMV-M) is planning to lay the keel of the craft early next month, before the successful tender is expected to be announced.

The Birdon LMV-M has been jointly designed with award-winning naval architects Incat Crowther and has been under construction since late last year at Henderson in WA.

Birdon General Manager – Defence, Joe Smith, said having a life-size operational proof of concept for testing and evaluation would bring forward aspects of the LMV-M project by up to two years, particularly with current global supply chain challenges.

“It is a significant investment by Birdon, an investment that wouldn’t necessarily be made by other organisations, but is reflective of our commitment to the project,” Mr Smith said.

“There is obviously some financial risk in developing a prototype but more so it takes risk out of the overall project because we will learn a lot through the process in terms of performance of the vessel and also in terms of integration and working practices with our partners.”

“We are confident that we have a compelling proposition both domestically and internationally, hence our willingness to embark on this type of initiative.”

This week the Federal Government received the Defence Strategic Review (DSR) into new hardware required to meet Australia’s national security needs, with an emphasis on a rapid procurement and preferably sovereign made capability for Pacific operations.

Having a proof of concept in the water creates a unique opportunity for Birdon to support that acceleration. The need for such a vessel has long been identified by Defence as a critical capability gap for regional operations.

“Championing the crucial role of small to medium enterprises in Australian manufacturing and supply chains is core to our offering … made with Australian steel and at Birdon’s own cost and risk,” Mr Smith said.

Under Defence’s request for tender the new vessel had to be able to carry a range of ADF vehicles including the huge Abrams M1A2 Main Battle Tank and the new Infantry Fighting Vehicle, service a minimum 10-person crew, through 4m swells for more than 500 nautical miles of open ocean without fuel resupply and be armed with two remote weapon stations and two .50 calibre machine guns.

Last year the Port Macquarie-based Birdon was awarded a whopping US$1.187 billion US Coast Guard contract to design and build 27 craft to protect their waterways.

Originally published as Family-owned engineering firm Birdon gambles on army vessel prototype to plug capability gap