Bush-washing: The erosion of Australian manufacturing

Many Aussie brands boast locally made heritage. But a closer look at where their items are produced tells a different story.

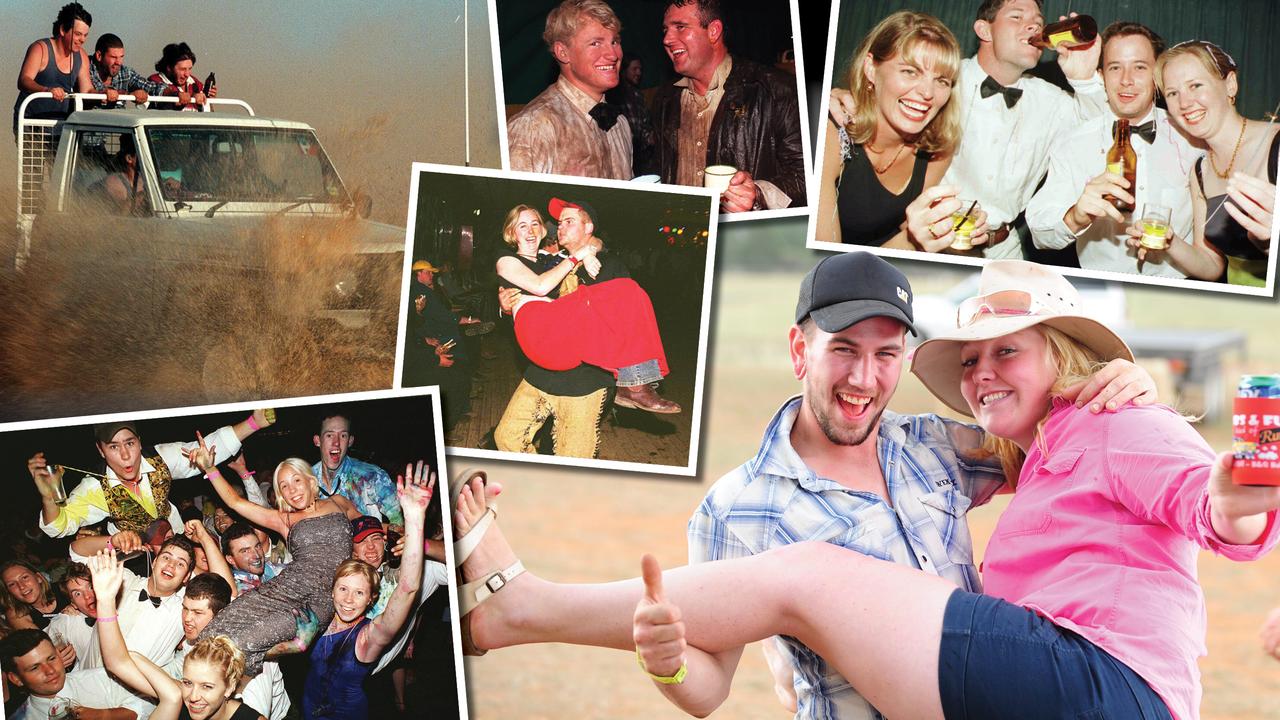

The image of the countryman or woman bedecked in a stockman’s hat, gleaming leather boots and a pair of moleskin trousers has been evocative of life in the Australian bush for more than a century.

But a closer look at the clothing tags tells a different story. While many iconic brands boast Australian-made credentials, manufacturing of a number of their goods takes place overseas.

After acquiring R.M.Williams in 2020, Aussie businessman Andrew ‘Twiggy’ Forrest said he wanted to bring the business back to being a wholly Australian label.

“We’re taking this show to only Australian made, which we understand is going to be difficult but I think has got to happen,” Mr Forrest told the Nine Network in 2021.

“It is easy course to make a pair of jeans five or 10 times less in Bangladesh in a sweat shop wherever else. That is what big brands do. We will not do that. We cop it five or 10 times more but we will bring the skills here.

“Every Australian will know they are Australian-made jeans and not made by kids in sweat shops.”

Three years on, and a quick search of the brand’s online shop reveals Twiggy’s promise to bring manufacturing back onshore was indeed much easier said than done.

Many of the brand’s clothing items are still produced using imported fibres or manufactured overseas, and it’s not the only country outfitter that relies on offshore production.

The Weekly Times asked rural clothing brands R.M.Williams, Driza-Bone, Rossi and RB Sellars what percentage of their stock was made in Australia, and all declined to provide figures.

R.M. Williams chief sustainability officer Angela Wilkie said 100 per cent of the brand’s boots and belts were made in its Adelaide workshop, “and the business is working to not only safeguard that capability but expand it”.

Working to expand their domestic production, Ms Wilkie said the company has brought back the Certificate III in Leather Craftsmanship to South Australia.

But the company still faced “many challenges” as it works to increase high-volume manufacturing in Australia.

Ms Wilkie and representatives of other brands explained ramping up domestic production was a difficult, slow process. Limitations included physical capacity of manufacturing plants, availability of trained workers and consumer price expectations were all barriers to growth.

“ … the entire infrastructure has been eroded, from machine builders, to laundries, to skilled workforce, to raw material suppliers, and the reality that manufacturing in Australia has an inherently higher cost,” Ms Wilkie said.

“Scaling Australian manufacturing of clothing requires a staged approach to build the skills of onshore workers, increase our capacity and increase onshore production partners.”

CHECK THE LABEL

To measure how well rural clothing brands live up to their true-blue Aussie images, The Weekly Times selected a shopping basket of products from each company’s website.

Of 11 R.M.Williams products selected across categories, seven were produced in Australia while four were imported.

The Aussie-made buys included the $649 R.M. Williams Comfort Craftsman boot, the Ramco rigid jeans and women’s Kilda crew sweater. But R.M.’s $179 Patterson Creek jacket was imported.

Of 10 Driza-Bone items randomly selected, six were made in Australia while four were described as “designed in Australia”.

Driza-Bone chief executive Caroline Elliott said the company’s onshore production capacity was at its maximum, and required additional manufacturing to be done overseas.

“The Australian factory is at full capacity manufacturing Driza-Bone’s iconic Heritage range of oilskin products, so the seasonal range is manufactured offshore to meet demand for our products,” Ms Elliott said.

A survey of RB Sellars clothing range selected 20 items at random. All 20 items of male and female clothing were made abroad, predominantly in mainland China.

Established in regional Victoria in the mid-1990s, the company is owned by the Propel Group, which also owns Driza-Bone and Rossi Boots.

RB Sellars general manager Adam Wilkinson said the company focuses on using Australian fibres such as cotton and Merino wool, but production is sent offshore in a bid to keep prices down for consumers.

Blundstone – a “100 per cent Tasmanian privately owned” company according to its website – manufactures its gumboots in Tasmania, but “to continue to supply the quality boots you know and love … we work closely with five key manufacturing partners around the globe to produce our leather products in Vietnam, India, China, Mexico and Thailand” the website says.

Even Akubra, which lives up to its Australian-made mantra with most of its hats, sells some straw versions that come from Ecuador and are just partially manufactured in Australia.

STITCHED UP

Construction Forestry, Maritime, Mining and Energy Union national secretary of manufacturing Jenny Kruschel said while there was great potential for regional communities to benefit from Australian manufacturing, more investment in the sector was needed.

“We want government to support Australian textile clothing footwear products … it may be the carpet that goes in social housing, or garments worn in defence … they could buy more Australian content in their tenders,” Ms Kruschel said.

A report published by The Australian Fashion Council in 2021 showed more than 489,000 people worked across the industry, contributing about $27.2 billion to the economy in 2021. However, of that figure, manufacturing accounted for just $1.5 billion.

Ms Kruschel said more commitment to training workers was also critical to shore up a solid workforce to bolster the domestic manufacturing industry.

“If you look at what’s happening overseas, they say (manufacturing) is cheaper, but there’s a reason for that,” she said. “People are getting exploited overseas … they don’t have the same environmental laws overseas, or the same workers’ rights.”

Ms Kruschel said consumers who were seeking out locally made clothing were paying more attention to brand credentials, and companies that were transparent stood to gain.

“There’s already a trend that consumers are starting to buy more Australian-made,” Ms Kruschel said. “There’s a need to really start letting people know that Australian-made is there, and there is variety.”