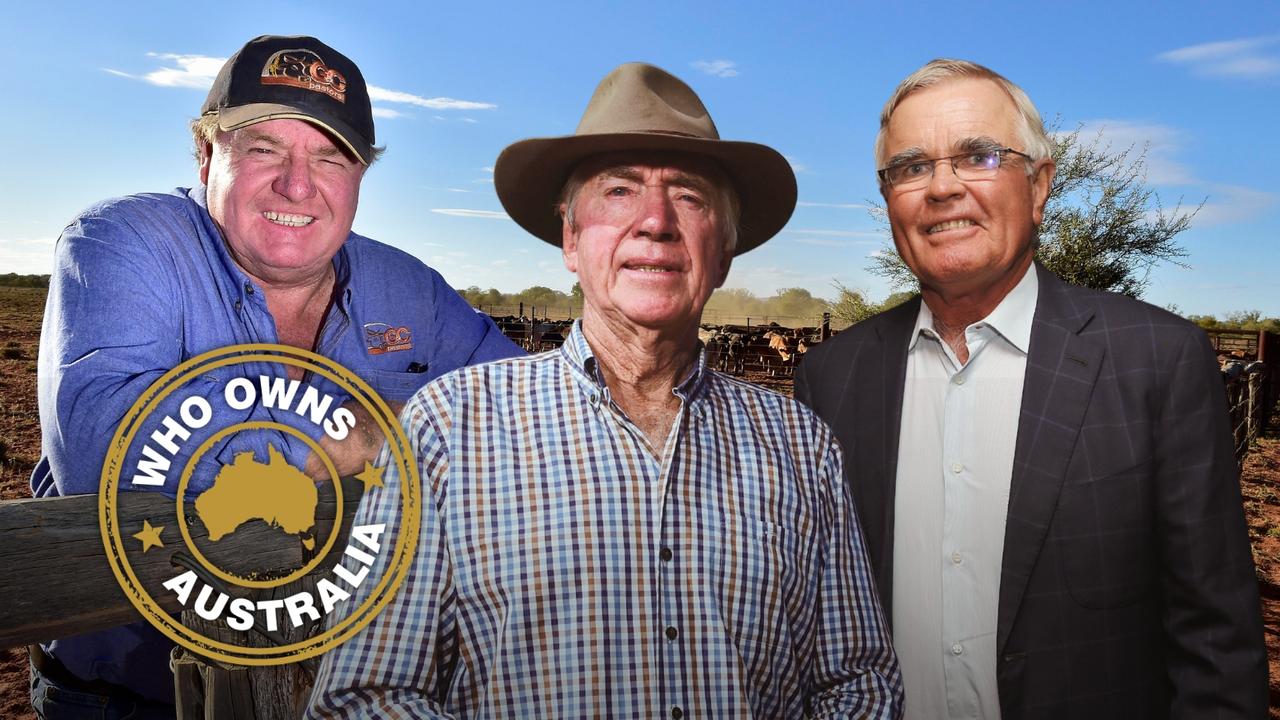

The Lee family of Australian Country Choice are the billionaires of beef

Discover how Anthony Lee and his brothers have pivoted Australia’s largest vertically integrated beef company running 300,000 cattle for the future.

Anthony Lee leans back in his chair in the boardroom of his family’s beef empire in Brisbane’s industrial suburbia, and grins.

“To be honest, mate, forever,” he says with a chuckle.

It’s a telling response from the grounded 44-year-old when asked precisely how long he’s been involved in the day-to-day operations of Australian Country Choice, the nation’s largest vertically integrated beef business valued at a whopping $1.8 billion.

And, while it’s an answer that probably doesn’t require much thought, it does provide Anthony with an opportunity for reflection.

“As a six, seven, eight or nine-year-old going over to Dad’s place would always involve sitting around the office (ACC’s headquarters and abattoir at Cannon Hill, 10km from the Brisbane CBD) for a couple of hours after school, eating the biscuits and getting into all sorts of strife,” he recalls fondly.

“At about 15 I started working part-time in the abattoir, we’re talking Friday nights, some weekends, school holidays. It was really bottom, bottom-of-the-barrel stuff – learning from the floor up, which was at the time difficult because, one, I was the boss’s son and, two, my mates weren’t doing anything remotely like this.

“There would also be trips out west with Dad. I remember he had a little 182 (Cessna four-seater aeroplane) that we would bounce around in going to a bull sale, or going to some of the properties and catching up with the managers.

“In hindsight it was the best, absolutely the best-possible way to learn the business.”

Dad is, of course, Trevor Lee, the now rich lister who founded ACC in 1968, eight years after his father, Norm, purchased the company’s foundation Brindley Park property near Roma.

The business now runs 300,000 cattle on 42 properties spanning 1.75 million hectares of Queensland, producing 75,000 tonnes of beef annually and employing 1500 workers.

Trevor remains on the board but has handed running of the day-to-day business to Anthony, as chief executive. Anthony’s 43-year-old brother, Michael, is also a director of the company and heads up the business development arm. A board that includes independent directors has ensured a relatively seamless transition from one generation to the next.

“Dad and I have differing views on things, as everyone does, but he is pretty good at letting me run my show as I see fit, as long as the performance is right,” Anthony says.

IN THE BLOOD

Growing up, Anthony wasn’t always destined to have a direct hands-on role in the ACC business, but that said he did align himself with the agriculture industry early on.

He studied Indonesian at school “because my dad would say, ‘There are 250 million people up there in that market, and that’s the future’.”

“So, I suppose there was always an expectation that I’d be part of it (in some form).”

After completing university, Anthony spent five years travelling overseas and working in different industries.

Still unsure what he wanted to do, his father approached him with his grand plans of increasing the ACC processing capabilities and invited him to become involved.

“He offered me a couple of years of training in another facility, and then I could run that part of the business. So, I came back to Australia, went down to Melbourne, and worked at different businesses to learn about further processing.”

Anthony has been full-time at ACC since 2006. He succeeded well-known beef industry identity David Foote as chief executive in late 2020.

When questioned on the side of the business he most aligns with, Anthony’s response is probably unsurprising for a kid who was born and bred in the city but always held a passion for people and the great outdoors.

“I really love the agri side, the rural operations,” he says in reference to ACC’s mammoth property portfolio which is equivalent to the size of Fiji and large enough to elevate the Lee family name to the list of Australia’s biggest landholders.

“The people who work on the stations – they live it. It’s their life, their passion, and their work. It’s very grounding. They’re just great people, and there’s a different energy in that part of the business,” he says.

“Processing is intense, full-on. There are a lot of challenges there, but when I’m out at events like a camp draft, I feel at my best. I enjoy spending time with the young ringers and hearing their stories.”

The ACC property portfolio comprises eight main aggregations including the 942,500-hectare Barkly Downs property west of Mt Isa in far northwest Queensland, acquired following a five-year joint venture with another famous Queensland beef family, the Actons.

There’s also the Wellclose Group of eight stations spanning 225,000 hectares at Adavale, near Charleville, and the Babbiloora Group spread across 144,000 hectares of country near Augathella.

A further 7700 hectares of farming country on the Western Downs is used to grow feed to supply the company’s three feedlots – Opal Creek at Dunmore, Brindley Park and Brisbane Valley at Esk – which have a combined capacity of 60,000 cattle.

HEDGING THEIR BETS

The ACC business is fairly evenly split between the pastoral and processing divisions, which Anthony describes as a deliberate strategy to enable the company to be hedged across the supply chain and best handle market fluctuations.

“When the cattle markets are down, the meat markets might be up, and vice versa,” Anthony says.

“This way, we’re winning and losing in different areas, but overall, the return balances out.”

While processing is more laborious because of its intensity, from a value perspective, the company has much more capital tied up in the rural assets.

The ACC vertically integrated system works almost on a north-south basis, beginning on the company’s vast northern breeding stations where cows calve on native grasses.

Once taken off their mothers they are transported to backgrounding properties further south that are better developed with pastures, and where animals are subject to more intense management with a focus on weight gain.

Once they hit a certain weight, they are moved on to one of the three feedlots, before ultimately ending up at Cannon Hill for processing and packaging.

For years, ACC was perhaps best-known for its longstanding contract with Coles, which saw it breed, feed and process more than half of the beef sold by the supermarket giant each year. The deal came to an end in 2019 following a high-profile contractual dispute that wound up in the courts before being settled.

Anthony describes the end of the Coles relationship as “massive” but something that provided a “healthy” turning point for the business.

“We had an exclusive deal with Coles for 20 years, we had supplied them for a lot longer, and had built our entire business around that model,” he says.

“Our people, assets, and even our biological assets were all tailored to that partnership. Then, when the partnership ended, we had three years to replace Coles with other customers. Imagine: we had 4.5 million acres of land, 300,000 cattle, three feedlots, and 6000-head-a-week meatworks to fill. And on top of that, we were dealing with a global pandemic.

“It was an intense process.”

LOOK OUTSIDE THE SQUARE

Anthony says the move forced ACC to tender for and win new business on merit and reassess the direction of the company.

“It made us look at the business from the ground up,” he says.

“We examined whether we as a business were right-sized, right-costed and right-valued.”

What followed was an overhaul of the way the business operated.

Previously, under the Coles agreement, “everything was done the same way” with the breeding, feeding, processing and packaging of initially a lower-cost Brahman animal and later a more “Queensland flatback” Angus-Brahman composite.

“You can imagine, pivoting away from that was not just a case of changing the lid on the box. We brought in Wagyu, long-fed Angus, organics and all these other styles of animals which have just completely different cut plans, completely different packaging requirements,” Anthony says.

“Just the learning for everyone (was incredible) and it wasn’t like we said ‘we’ve got six months, just take your time’ it was like ‘we need to go, we need to go, the next customer is coming in, get ready’.”

When ACC held the Coles contract, the business had a 70 per cent focus on the domestic market with export sales – made on behalf of Coles — accounting for the other 30 per cent. That ratio has now been flipped to 60:40 in favour of exports.

ACC’s domestic focus includes cattle fed and processed for major supermarket chains Woolworths and Aldi as well as Angus and Wagyu for high-end customers.

On the export front, ACC has also introduced its own brands into the mix which account for about 20 per cent of processing capacity but 40 per cent of meat sales.

Product is exported to about 40 countries, including Japan, Taiwan, Korea and the US, and Anthony expects that number to grow.

He describes the business as being well placed to capitalise on growing demand for high-quality protein, particularly in regions such as Asia, where population growth and rising incomes are fuelling orders.

FLATTENING THE CURVES

The volatile nature of the global beef industry is something that concerns Anthony.

In recent years, factors such as drought, fluctuating demand and government policy have resulted in beef prices soaring to record highs one minute, and devastating lows the next.

In January 2022, Australia’s benchmark Eastern Young Cattle Indicator reached a record 1191 cents a kilogram carcass weight but by late last year had fallen to less than 400 cents a kilogram, despite quite strong industry fundamentals.

It led to many producers blaming the price crash on bleak seasonal forecasts from the Bureau of Meteorology, prompting a flood of cattle on to the market, which were not realised in some major beef production regions.

At the start of October this year, the indicator was hovering around 630 cents a kilogram. Anthony reckons the volatility in the cattle market is the worst he has ever seen.

“The highs have been extreme, and then there are sharp drops,” he says.

“You’ve seen prices fall to as low as $2 a kilogram in some cases, which is just crazy. We don’t want that kind of volatility – it makes it really hard to plan and run a sustainable operation.

“A more stable price, even if it’s lower, would be far better for everyone involved. But with climate change, extreme weather events, and shifting global markets, it’s hard to see things getting less volatile anytime soon.”

To help counter the peaks and troughs, and with ACC nearing the end of its transition from one major customer to multiple, Anthony says the next step on the company’s growth trajectory is diversification.

“If something like foot-and-mouth or lumpy skin disease hit, it would be catastrophic for the industry. That’s why our diversification strategy is so important,” Anthony says.

“We’ve learned from the Coles transition – when the market shifts, you need to be nimble.”

DIVERSIFICATION STRATEGY

The business has turned its attention to potential new opportunities with plant-based proteins. Anthony says “we’re happy to produce what customers want, but personally, I don’t see plant-based meats taking over – it will find its level, just like organics did, but it won’t dominate”.

ACC has also invested in the industrial hemp sector through its part ownership of Hemp Farms Australia and is now investigating opportunities with small-stock livestock species.

Enter Michael Lee who, like his older brother, has been involved in the family business since his youth and has worked across every facet of the company “from the tripe room to three and a half years out west on a breeding property”.

Michael says, with large chunks of the expansive ACC property portfolio well suited for sheep production, the business explored the potential for sheepmeat production, before zeroing in on another protein: goatmeat.

Part of the reasoning behind this was to help counter vegetation regrowth on the ACC station country.

It also didn’t hurt that goatmeat prices had risen to $10.50 a kilogram carcass weight at the start of this decade “so when you ran the numbers from a commercial perspective, goats were more profitable than sheep or cattle”.

“Essentially, we saw that we could turn a liability into an asset,” Michael says.

“Goats could graze on hundreds of thousands of acres of land that couldn’t be used otherwise, allowing it to regenerate over a season or two.

“Our long-term plan is to set up a vertically integrated model, replicating what we do with beef. We’re working on creating a consistent, high-quality product with the right genetics, numbers, and supply chain.”

Michael estimates that in the early 2010s, the ACC properties were home to about 40,000 feral goats, which were sporadically mustered with the funds generated from their sale used to help educate the children of property managers.

“At that time goats were worth next to nothing and we didn’t consider them a commercially viable option,” he says.

“Now, looking back, that would have been a very cheap start to the business.”

GETTING INTO GOATS

The Lees considered the Wellclose properties near Charleville as ideal to put their goat theory into practice.

The business invested heavily, spending upwards of $5 million on water infrastructure and exclusion fencing on the property and bringing in 10,000 pure rangeland nannies.

ACC experimented with stocking numbers – “on one hand we wanted them to have an impact on regrowth … on the other hand we didn’t want to overstock” – and vermin control – “a two kilogram goat kid is ideal prey for dingoes, pigs and eagles” – before introducing Boer goats to kick off a breeding program.

The first cross instantly improved yields by 5-7 per cent. The company has also introduced more hybrid vigour into the herd – which now totals 30,000 head – to improve survivability.

After rapid expansion during 2021-22, the business is now focusing on production and breeding, improving yields, reducing mortality, and working on the establishment of feedlots and depots.

While it is trialling rations and stocking rates to create a proper supply chain, similar to beef, Michael says the goatmeat market dropping to $3 a kilogram makes expanding large-scale feedlots commercially unviable.

“However, we are preparing for when the market improves. With goats’ shorter gestation periods (five months compared to cattle’s nine) and high kidding percentages (of 120-150 per cent), numbers can increase quickly.”

Michael says one of the challenges with the Australian goatmeat industry is a lack of custom processing facilities. In Queensland there is only one large export meatworks – Western Meats at Charleville – licensed to process goats. Another, at Bourke, in western NSW came online recently.

“The industry needs more processors to grow and offer competition, allowing producers to retain their meat and build their brands,” he says.

SUSTAINABILITY FOCUS

Back at Cannon Hill, Anthony describes sustainability as being at the core of everything the business is doing.

He says businesses the size of ACC’s have to be leaders in this space because the pressure is coming from all sides, including governments, consumers and even retailers.

He acknowledges the focus on the agriculture industry, especially the livestock sector, in regards to meeting net-zero targets and reducing emissions, especially methane.

“For us, 85 per cent of our emissions come from methane, and that’s a big challenge,” Anthony says.

“We’re still in the process of understanding the true impact of methane and what the most effective solutions are. We’re committed to doing what’s right for the environment, but we also have to be realistic.

“There’s no silver bullet when it comes to reducing methane emissions, at least not yet, and we have to balance sustainability with the economics of the business.”

That said, ACC is investing in research and development to find solutions, whether it’s around feed supplements that reduce methane output or more efficient farming practices.

The company is also committed to exploring efficiencies on the genetics side – selecting cattle that are more efficient in terms of both feed conversion and emissions.

Anthony sees the social licence to operate as the biggest challenge to Australian agriculture.

He says, in many respects, the industry has lost touch with its city consumers who “don’t understand what we do”. He laments a lack of education about agriculture, and where food comes from, in Australian schools.

“People are finishing school not only without hearing about agriculture but hearing negatively about it,” Anthony says.

“So, the most important thing we can do is unite as an industry and get it taught at schools. It’s in the curriculum today – food and fibre – but it’s just not getting taught enough.

“We need to help people get a better understanding for two reasons: one, we want great people in our industry to do it more sustainably, to do it better, to do more with less; and two, for those not coming into it, to have an appreciation of what an essential service agriculture is.”

Not one to mince his words, longtime Lee lieutenant David Foote, who spent two decades at the coalface of ACC as managing director, says having the next-generation Lees at the top of the company is particularly important.

“I shouldn’t say it but there’s enough of us old, grey, bald-headed blokes around the table,” he says, in a self-mocking way given he remains on the ACC board.

“It’s really good to see the next generation come through.”