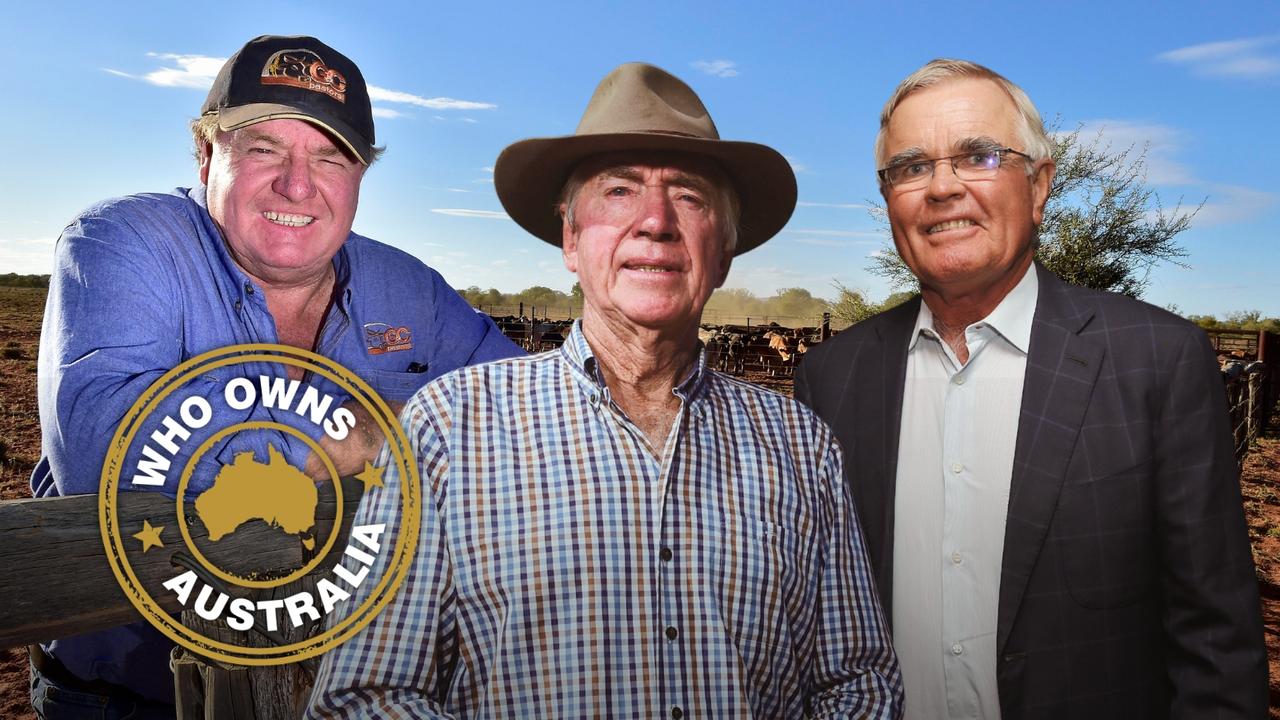

The Angus family opens Queensland’s new Signature Onfarm meatworks

The Angus family’s new on-farm abattoir completes their ambitious plan to breed, feed, muster, slaughter and deliver the perfect beef.

The orange sun is setting over the soft brigalow downs that stretch from the green lawns of the Angus family’s sprawling Queenslander homestead to the distant horizon, as seven glossy stock horses are saddled for a twilight muster.

The family that plays together stays together is a truism for the Angus family, as Blair and Josie Angus, their four adult children Lauren, Maddie, John and David, and niece Tess Camm, ride out on to the glowing plains of Kimberley Station to bring a mob of black and russet red cows and calves back to the home paddock.

Broad brimmed hats, blue jeans, big belts and RM Williams shirts are the unconscious uniform of the day, just as the riding and mustering are both effortless and graceful, and the horses – bred and trained as top campdrafting steeds – simply magnificent.

“I just love life,” says Blair Angus, highly respected central Queensland cattleman and a former chair of Beef Australia, the triennial annual expo and calendar highlight of the Australian beef cattle industry, as he slices a tray of massive roasted rib steaks for the family dinner.

“Why wouldn’t I; there’s not much that keeps me awake at night, not even what we are doing now.”

What the Angus family – all of them – is doing now, is building, owning and operating a massive new $37 million meatworks on neighbouring Sondella station, 150 kilometres north of Clermont and 60 kilometres northwest of coal mining town Moranbah, in central Queensland.

From a dream and an ambitious vision seven years ago, the state-of-the-art Signature Onfarm abattoir at Sondella processed its first cattle last November and is gradually cranking up to handle as many as 200 cattle a day.

It is a bold move by one of Australia’s best-known cattle families.

Signature Onfarm is the first new major meatworks opened in Queensland for three decades.

It is also one of the few family-opened meat processing operations anywhere in Australia, and among only a handful of commercial abattoirs located remotely. Even fewer are above the tropic of Capricorn in Northern Australia, in the underdeveloped and sparsely populated outback North.

“People like to say we have built a meatworks in the middle of nowhere,” laughs Josie Angus, who has been the driving force behind getting the abattoir financed, approved, built, staffed and open. “We just say that, to us, it’s the centre of everything.”

To outsiders, the decision by the Angus family to build a boutique meatworks on one of their central Queensland cattle stations, 250 kilometres inland from the coast and 450 kilometres from Rockhampton, might look a natural progression in their booming cattle and beef business.

For a start, the family on Blair’s side is descended from northern Scotland and Aberdeenshire, sharing their surname and place of origin with the popular Scottish cattle breed that has now spread around the world, renowned for its meat quality.

“What else could we have been but cattlemen?,” asks Blair Angus, 55, wryly.

The Angus Pastoral Company he heads already owns and runs 35,000 cattle, joining 12,000 breeding cows every year that Blair, and his father John before him, have carefully selected and bred over decades.

The result is a composite line that is an established cross between the black Aberdeen Angus and Belmont Reds, a breed that adds tick resistance and “do-ability” to the Angus breed’s renowned meat flavour and texture, and quiet temperament.

“It’s worked really well for us,” says Josie. “It’s a line of cattle that is well adapted to the North, has the right temperament and fertility, that produces excellent quality meat and can make you more money.

“We focus on selecting for a moderate frame, a not big-boned animal, but one that will give a good saleable meat yield. And then we look for fine hair.”

Josie Angus calls it her husband’s quirky “witchdoctor beliefs”, his magic theories, about cattle selection.

“Blair is certain the finest of hair (on the animal) has a direct correlation with the finest of meat texture, and that coarse hair indicates rough meat texture,” she explains, as the dying sun turns the finest of hair on the neck of one of the freshly-mustered cows into spun gold.

“He is full of these theories but they all come back to the eating quality of the meat. And from what all our customers say about our beef, he seems to be right.”

The family owns 160,000 hectares of cattle country and four properties, with prized 120,000-hectare Gulf cattle station, Carpentaria Downs, near Einasleigh – bought in 2005 from the Acton family, their close friends and another member of Queensland’s cattle royalty – the jewel in the Angus crown.

They have been branding and selling their own beef to markets around the world since 1999, when the Angus’s first and well-known Kimberley Red beef brand began, showcasing meat from the cattle raised on their home property but, back in those days, processed and packed for them in third-party meatworks.

Since then, three other beef brands have been added. There is the Angus Pastoral Company brand which is exported primarily to European markets, and their top tier, premium low-volume “Oino Gustus” brand (it is the Gaelic origin of the word Angus and also means ‘first choice’).

Most recently has been added the new Sondella label, used for meat from cattle bred by other local producers but killed at their new Signature Onfarm abattoir at Sondella station.

Until now, the Angus Pastoral Company business has been breeding cattle on Carpentaria Downs station, bringing the young eight-month-old weaned steers to the grassy paddocks of Kimberley, Sondella and neighbouring Chesterfield station – all owned by the Angus family – for backgrounding (growing out) for the next two years, and then transporting them to feedlots down on the Darling Downs for final fattening.

Their own grass-fed feedlot at Sondella, begun and expanded since 2006, can house 2000 cattle, with plans to grow their own hay and expand to 5000 head soon.

About 15,000 of their own cattle (350 a week) plus some bought from other breeders, are then processed once they reach prime weight for the family’s meat business, Signature Beef – run by 30-year-old general manager and niece Tess Camm – at the cooperative-owned and export-accredited Casino meatworks in northern NSW.

There the resulting beef, still all owned Signature Beef company, is classed and packaged into its three distinctive beef brands. About 40 per cent is exported to more than 30 countries and the rest sold domestically, much of it direct to restaurants.

“We are one of Casino’s biggest customers and it will stay that way; it is not like we are dropping them because we now have our own abattoir,” says Josie Angus.

“This (the Sondella meatworks) is more a growth step for our business; we will continue to send cattle to Casino but will also be processing up to 200 a day here for ourselves and other cattle businesses when we reach our full capacity.

“A lot of cattle from across the North will end up coming here; an option that wasn’t there before for producers and which saves on transport costs and time.”

As the refrigerated container truck pulls away from the shiny loading dock at the Signature Onfarm abattoir, Josie Angus breathes a sigh of relief.

It’s the third truck in the past week that has headed off down the sealed highway to Sydney with beef cuts all neatly packaged under the Sondella brand bound for three key customers.

All the distinctive yellow boxes are emblazoned with the family’s promise and Signature Beef credo, finished with the flourish of a signature from Blair and Josie Angus. “From our land to your home, we are proud to share this piece of our heritage with you.”

The truck’s departure is further evidence to all that the mammoth and expensive abattoir project, labelled a risk and a liability by many, is up and running, although not yet at full capacity. It’s been four years in the actual making. But it’s been even longer since the family – all squashed in a car on a road trip across the US in 2015 to visit twin daughter Lauren, now 26, who was studying for degree in meat science at Colorado University – jointly decide to take the plunge and build their own abattoir on their own land.

On their return, the initial Development Application for the Sondella meatworks was lodged with the local Isaac Regional council in September 2015. The Angus family had early hopes it would be up and running by 2019.

Josie Angus, who met Blair at a campdraft in the early 1990s and married him in 1994, laughs at all the memories.

“There was there was a long time when Blair swore he never wanted to own a truck or an abattoir, and here we are with both,” she grins.

Josie recalls the early days in 2013-14 when access to abattoirs was very tight for producers like the Angus Pastoral Company looking for meatworks to do contract or ‘service’ kills for them, where the farmer still owns the cattle and resulting meat rather than selling it to a big meat processing company such as Teys, JBS or Australian Country Choice at the meatworks gates.

At the same time there high herd numbers, drought and big export orders, so all the abattoir lines were full. Several councils then approached the Angus family to see if they would back – either financially or through cattle throughput pledges – some of the many proposals then being floated by councils to build new abattoirs in places like Richmond, Julia Creek, Cloncurry and Emerald.

“So we threw the idea around and even went looking at abattoir designs in the USA. And it was on that road trip we questioned as a family why we would go into a council proposal as a minority investor.

“The kids and us all decided we should instead put our own skin in the game and do it ourselves. Why not be hands-on and do it ourselves and on our own farm?”

It’s been a massive undertaking for the family – and a very fast learning curve – with Josie and Tess responsible for most of the detail of building the abattoir, getting it approved and up and running.

While the state and federal governments were supportive of the project – a $5 million Regional Jobs and Investment grant from the Federal Government in early 2018 speeded up initial planning – approvals and red tape hurdles at a local council level stalled construction for four years.

But the biggest leap forward came in 2019 with the announcement that the nascent Northern Australia Infrastructure Fund would loan $24 million to help build the central Queensland meatworks, one of the biggest financial decisions yet made by NAIF.

The then-federal Minister for Northern Australia Matt Canavan, who lives in nearby Rockhampton, said the loan would speed up construction of the 50,000 head-a-year processing facility and help finance its bespoke aged beef chillers, value-adding capability to prepared retail meat portions and ready-to-serve meals, waste water infrastructure, and access roads.

Blair Angus says the NAIF funding was a game-changer for the project. Combined with a $10 million loan from the ANZ Bank, the family-owned and operated bush meatworks was suddenly a reality.

The first sod was eventually turned in late 2020, construction at full tilt during 2021 and the first trial run of 10 cattle processed through the new plant late last year. The first commercial meat from the Signature Onfarm abattoir left Sondella in late January.

“This isn’t about visions of grandeur, nor is it all about us processing all our own cattle here,” says Blair Angus. “It’s about creating a blueprint, bringing meat processing back to where the cattle are, reducing the huge impact on our roads of transporting all the cattle to the cities where the abattoirs now are.

“Once you put beef in a box, you can get three times as many ‘cattle’ on a truck. It’s more efficient, much more sustainable, and more food secure to have many more and smaller abattoirs like ours spread across the regions, capturing more economic value in the regions and getting the settings right that encourage more development in Northern Australia, where we have lived all our lives.”

From the outside, the scale of the undertaking is obvious. A giant long processing plant – cattle yards at one end and truck loading facility at the other – sits almost incongruously amid the yellow grass plains. Cattle graze all around in the vast paddocks spotted with brigalow, belah and bauhinia trees.

The layout is all based on humane animal welfare principles, much of it on the advice of acclaimed animal behaviouralist Dr Temple Grandin, who was one of Lauren Angus’s lecturers at her American university.

Inside, with all its glistening machinery and stainless steel refrigerated rooms, the focus is on turning out high quality beef, much of it hung and aged for two days in special dry-aged chilling rooms.

There is an emphasis on yield too, an almost nose-to-tail approach to ensure as much of the animal carcass becomes edible and saleable produce as possible. This returns more profit to the producer and owners of the cattle but also delivers more product volume and range to Signature Beef to market and sell.

Blair Angus says the aim is not on fast processing and daily capacity throughput, but turning more than 56 per cent of the animal’s weight into meat yield through careful and deliberate processing choices, rather than the Australian industry’s average of just 52 per cent (see breakout).

He hopes to eventually achieve even better, perhaps even an 8-10 per cent yield boost, by more judicious trimming.

“That’s our main KPI (Key Performance Indicator), getting as much value creation as we can from each beast; that why how we do things here is a bit unique,” says Blair Angus. “Our other KPI is keeping all of our customers happy.”

Tess Camm calls it a “bespoke approach” to meat processing, meeting the specific needs of myriad customers. More than 1600 different cuts can be produced and packaged in the meatworks to meet specific orders, including many products that use offal.

Currently the meatworks is processing cattle two days a week as its gears up to full production, with 20 new employees learning the ropes from how to move stock and kill cattle, to how to use sharp knives in the boning room, what each cut and trim is and how to operate a forklift.

In early April when AgJournal visited the new abattoir, the 50-head cattle kill had just been completed and the team-in-training had moved into the boning room.

In line with the family’s philosophy that they must know how to do everything themselves before asking employees to do it, all four adult Angus offspring are hard at work.

High on raised platform, eldest son John Angus, 23, is brandishing a massive sharp knife as he slices full hung and aged carcasses into major parts. Below on the boning room table, youngest son David, 21, his white coat covered in dried blood, is dividing parts of the carcass into subprimal cuts including bowler blade, oyster blade and chuck tenders.

Daughter Lauren, 26, is in the offal room, trying to work out how to best pack oesophagus into a box, while her twin Maddy is assigned to the cryovac machine that delivers finished cuts into small packs ready for restaurant and hotel kitchen orders.

All around are other employees also learning the ropes. One is a young meat apprentice from nearby Moranbah, another a university graduate working as jackaroo – and now meat processor – for Angus Pastoral Company, and a third a Sudanese man who has joined the team after earlier experience in abattoirs near Brisbane.

“One of our fundamental goals is to introduce more people from the cattle industry to the beef industry; to learn more about meat processing post-farmgate, because that fundamental link between the farm and food has been lost in Australia,” says a passionate Josie Angus.

Back up the dirt drive is the $1.5 million new staff village where the 70 workers that the meatworks will need to man its one-shift-a day, five-days-a-week, operations, can permanently live in their own quarters, some with their families, if they need accommodation.

Meals are provided free in the communal kitchen and mess room, cooked by an on-staff chef. Above-award wages are on offer too, as keeping employees in such a remote location looks set to be a major challenge, especially with the nearby coal mines offering big shiny salaries.

Importing foreign labour is not the plan, instead the focus is on upskilling locals, training apprentices, providing more jobs locally, and keeping kids in the bush and the regions where they were born.

Back at the family’s home on Kimberley Station after the massive steaks have been eaten, the red wine is out and as green tree frogs hop intermittently across the veranda, Blair Angus talks confidently about the future.

He is optimistic the abattoir will be returning a profit in two years, enabling Signature Onfarm company to convert its NAIF loan to a lower interest commercial one. The immediate next step, hopefully by June, is seeing the meatworks granted export licence approval.

There are no plans to buy more cattle stations – certainly not to build a second abattoir – only dreams of maybe once in his lifetime breeding the “perfect beast”.

“I’m just still so excited about beef, what to look for in an animal that tells you it has tender meat, how to breed it and then how to prepare it and cook it; I love sharing my meal ideas with great chefs,” says Blair Angus, who travels widely and sells meat to chefs who cook for Shanghai billionaires and to butchers who supply the Queen.

“It all goes back to my dad. He taught me about cattle, but it was really when the beef slump hit in the early 70s and he bought a butcher’s ship in Bowen to get us through the tough times (Blair was just a child) that I learnt about boning out and meat cuts.

“That’s when I became fascinated by turning beef into food; that’s the excitement I want to pass on not just to my children, but to other regional kids, through this new venture.”

FULL DISCLOSURE CRUCIAL TO MEATWORKS SUCCESS

The big glass windows overlooking the boning room floor of the new Signature Onfarm meatworks trigger memories of the famous quote from former Beatle Sir Paul McCartney that quickly became a campaign slogan for the vegan movement.

“If slaughterhouses had glass walls, everyone would be a vegetarian …”

Young Signature Beef general manager Tess Camm, who has been a critical part of determining the design, meat flow and workings of the new abattoir, doesn’t see the windows between the retail area of the meatworks and its meat room as anything controversial.

“We are not ashamed of anything we do here; we are trying to be as transparent and open as possible,” says Camm, who on June 1 will be a key speaker at the 2022 Global Food Forum in Melbourne, sponsored by The Australian and Visy.

“So many cattle producers and locals want to come and have a look at what we have built and are curious about how an abattoir works; I’m surprised at how few have ever visited a meatworks when they are in the beef industry.

“But’s it’s good too; we want to break down that divide between the meat producing and processing sectors and show that working in an abattoir is a good and interesting job; maybe this is one way we can do that.”

Camm has been the problem solver for Josie and Blair Angus as their dream of building an abattoir turned into reality.

Besides her daily job supplying cattle to the Casino cooperative abattoir to satisfy the beef orders and requirements from Signature Beef’s regular overseas and Australian customers, Camm has been entrusted in finding both equipment and solutions to turn the new Sondella abattoir into a state-of-the-art bespoke beef processing plant.

“It’s been a hard journey, especially when sometimes there has been no one to turn to for advice or to answer a specific question because no other processor in Australia is doing yet; that’s when Google has been great,” she laughs.

But Camm is proud of what has been achieved at Sondella and its design and sustainability highlights. Animal welfare is paramount in the way the yards have been designed, and the cattle moved and killed.

Thanks to new technology, water use is very low for an abattoir of its size and scale, despite the need for top hygiene, floor washing and carcass cleaning using a lot of water.

Similarly increasing the dressed-out yields of the carcasses by minimal trimming and using almost every offal part – including bones sent to soup makers – has reduced waste. Any blood, waste and body parts that are leftover are slowly converted into compost and spread on the farm’s hay paddocks.

“And for the cattle, being able to process them here saves on the need for one extra day of transporting them 1350 kilometres south to Casino for us, and the same for other northern producers who will using the abattoir instead of sending them further south,” says Camm.

“Every day that cattle are outside your control affects the final meat quality just that little bit.

“Just imagine how well this meat will grade and taste when the animals are killed right next to the farm they were raised on and feedlot they were fattened in, in a custom designed abattoir built with the best animal welfare and stock movements in mind.”

For more information, program and tickets to the 2022 Global Food Forum, visit globalfoodforum.com.au