University of Melbourne team invent world’s fastest 3D printer, that is set to save lives

The world’s fastest 3D printer has been invented in Melbourne, and it’s capable of replicating the complex structures found in human organs and tissues in seconds — making it a lifesaver.

Victoria

Don't miss out on the headlines from Victoria. Followed categories will be added to My News.

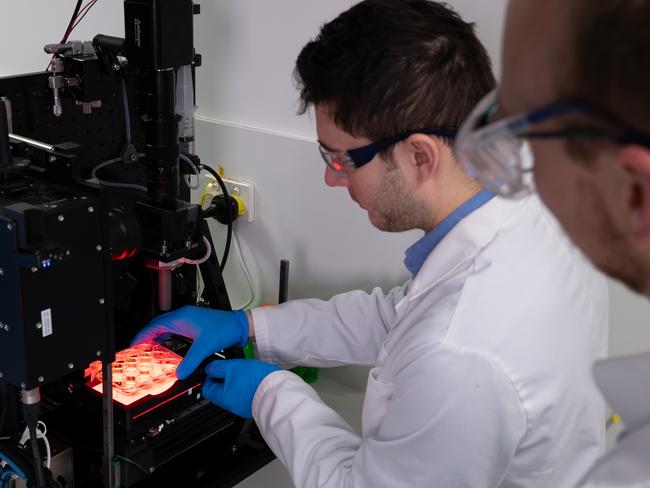

Melbourne researchers have invented the world’s fastest 3D printer that, for the first time, can replicate the complex structures found in human organs and tissues in just seconds.

The revolutionary technology, developed by University of Melbourne biomedical engineers, will save not only time and money, but also lives.

The researchers say their unique bioprinter will help fast-track drug trials, personalise cancer treatment and advance understanding of human biology and how diseases progress.

The team published their research on Thursday in the journal Nature.

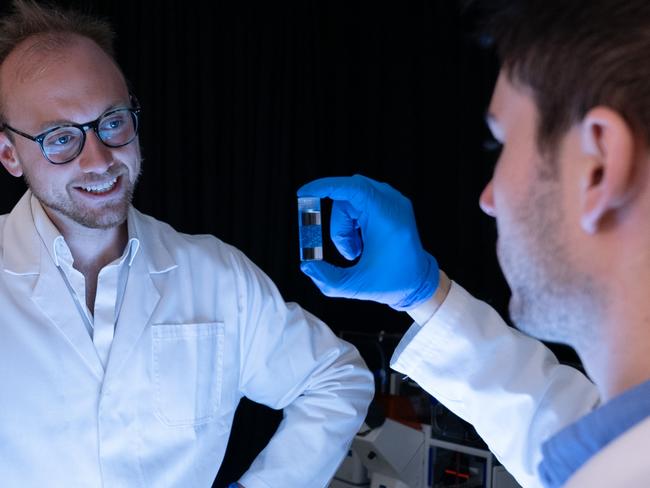

Lead author PhD student Callum Vidler said the team had created a new type of bio-fabrication technology that can accurately replicate the complex structures found in the tissues and organs throughout the body.

These will be used for research, not yet for human transplant, although that is a possibility down the track.

The bioprinter can also fabricate structures that closely mimic the wide range of tissues in the human body from brain, to cartilage and bone.

The groundbreaking technology also reduces the need for physical handling, uniquely ensuring the delicate structures remain intact and sterile throughout the process.

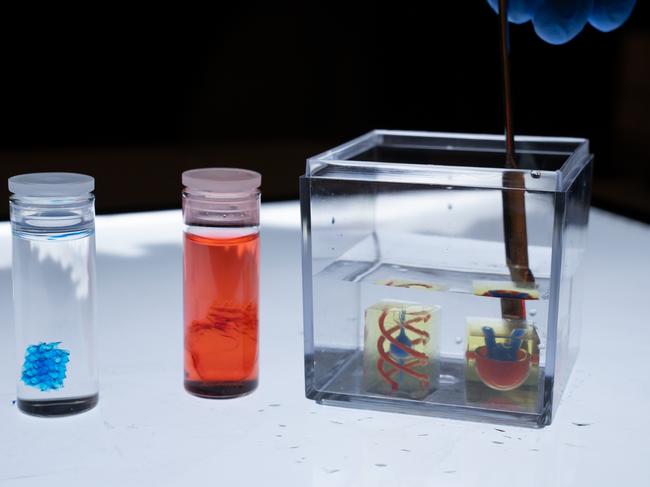

“A lot of 3D printing people are familiar with are using a hard plastic which flows when heated, just like a hot glue gun”,” Mr Vidler said. “The difference with our system is that we use a liquid which solidifies when exposed to light. It’s within this liquid material we suspend human cells, which are embedded when the structure forms.”

“We can create three-dimensional structures in tens of seconds, hundreds of times faster than other 3D printing approaches.”

He said the team envisioned a world where doctors could use the technology to tailor lifesaving treatments for patients.

“Instead of trying many different treatments, we could imagine a future where we could take a patient’s cells and using our system create hundreds of miniature models that mimic the patient’s disease, and then we can test all possible treatment combinations before ever touching the patient,” Mr Vidler said.

Senior author and head of the Collins BioMicrosystems Laboratory at the University of Melbourne David Collins said Mr Vidler had not just built the world’s fastest 3D printer. “He’s built the most suitable printer for 3D bioprinting applications that the world has seen,” he said.

Professor Collins said the new system used acoustic waves generated by a vibrating bubble to position cells within 3D printed structures.

“Our method provides the necessary head start for cells to develop into the complex tissues found in the human body,” Professor Collins said.

The next steps include investigating how the technology can be used for research applications, including collecting the data needed to apply for regulatory approval to use 3D printed tissues as the next generation of diagnostics.

“We are working with the Peter MacCallum Cancer Centre to see how this can be used as a point in the diagnostic pipeline,” Professor Collins said. “The hope would be determining which treatment is the best for a patient.”

He said creating organs for implantation was probably a long way away.

“That is as much to do with the regulatory hurdles as anything else,” he said.

Mr Vidler said what the team hoped for in the short term was to use the technology to advance the understanding of human disease.

“The hope is that we can now discover more effective therapies and new treatments to currently untreatable diseases,’ he said.

“The benefit is it allows us to advance or accelerate a lot of drug discovery, by offering a consistent, reproducible and scalable method to do so.

“Unfortunately, many of the medications and cosmetics we use still rely heavily on animal testing. We need to be looking at a way to change this. Not only will this result in huge savings for the medical sector by reducing the number of failed clinical trials, but we’ll be doing it in more sustainable and ethical way.”

Originally published as University of Melbourne team invent world’s fastest 3D printer, that is set to save lives