Arizona Lithium picks Koch’s Li-Pro DLE tech for Prairie Phase 1 development

Arizona Lithium is using Koch’s Li-Pro direct lithium extraction tech at Prairie after testing returned 98% lithium retention and 99% impurity rejection.

Stockhead

Don't miss out on the headlines from Stockhead. Followed categories will be added to My News.

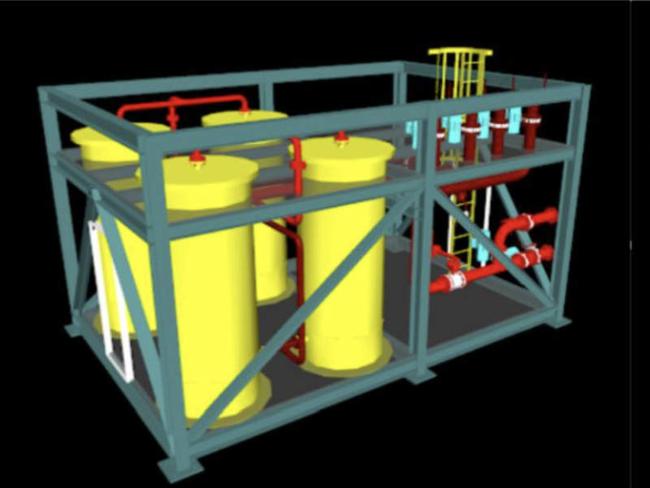

Special Report: Arizona Lithium has reached an agreement to deploy Koch Technology Solutions’ commercial-scale Li-Pro direct lithium extraction unit to enable production at its Prairie project Phase 1 development in Saskatchewan, Canada.

- Arizona Lithium deploying Koch Technology Solutions’ Li-Pro DLE tech at Prairie project

- Phase 1 development marks that largest DLE process ever deployed by Koch

- Li-Pro had achieved exceptional results with 98% lithium retention and 99% rejection of impurities

With the company’s Phase 1 plan targeting production of 150tpa lithium carbonate equivalent, this represents the largest DLE process ever deployed by Koch – a US-based leader in DLE innovation.

Arizona Lithium (ASX:AZL) had selected Koch’s Li-Pro technology after testing on Duperow brine sourced from Pad#1 returned exceptional results with about 98% lithium retention and average 99% rejection of impurities such as calcium, magnesium, sodium and potassium.

“We are extremely pleased to have signed an agreement to deploy Koch Technology Solutions Li-Pro DLE technology at our Prairie lithium project,” managing director Paul Lloyd said.

“This is another significant event in derisking the project. It is a pleasure to partner with a multinational corporation of such high quality as Koch Inc. and we look forward to the arrival of DLE facilities on site in Q2 this year.

“It has always been AZL’s intention to be a first mover and leader in oil field lithium brines and with the commitment of AZL to the Koch technology your company will be one of the first global companies to produce at commercial scale from an oil field brine project.”

Koch Technology Solutions director of strategic accounts Patrick O’Hern said the deployment of Li-Pro at Prairie is a major milestone for Koch.

“Continuing to de-risk the Li-Pro technology at scale highlights our ability to deliver on projects and lead the way in DLE technology,” he added.

Prairie development

Under AZL’s revised development plan, the company scaled-down its planned Phase 1 development from 6000tpa LCE to a commercial-scale, proof of concept facility at Pad#1 with initial production of 150tpa LCE.

This also reduced capex to first production from US$290m to a far more manageable US$22m.

Lithium produced under this stage will be used to de-risk end market opportunities where battery-grade samples are currently being tested by interested groups in Asia and North America.

Phase 1 will operate the Li-Pro commercial-scale “quad pot” DLE unit 24/7 at a rate of ~1000m3 of brine to de-risk its temperature, pressure and chemical constituents.

Should this prove successful, production can be quickly ramped up by installing additional Li-Pro units at Pad#1.

The completed facility could then be replicated at Pad#2 and Pad#3 and additional pad locations that are being investigated to further increase production.

This article was developed in collaboration with Arizona Lithium, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Originally published as Arizona Lithium picks Koch’s Li-Pro DLE tech for Prairie Phase 1 development