Fortescue is guiding a modest uplift in shipments as energy arm books large loss

Fortescue says the market for green products generally is ‘much, much larger’ than it previously believed, as the company looks to sink $1.8bn into its energy division this year.

Business

Don't miss out on the headlines from Business. Followed categories will be added to My News.

Fortescue is “doubling down’’ on green iron, and says the market for green products generally is “much, much larger” than it previously believed, as the company looks to sink $US1.2bn ($1.8bn) into its energy division this year.

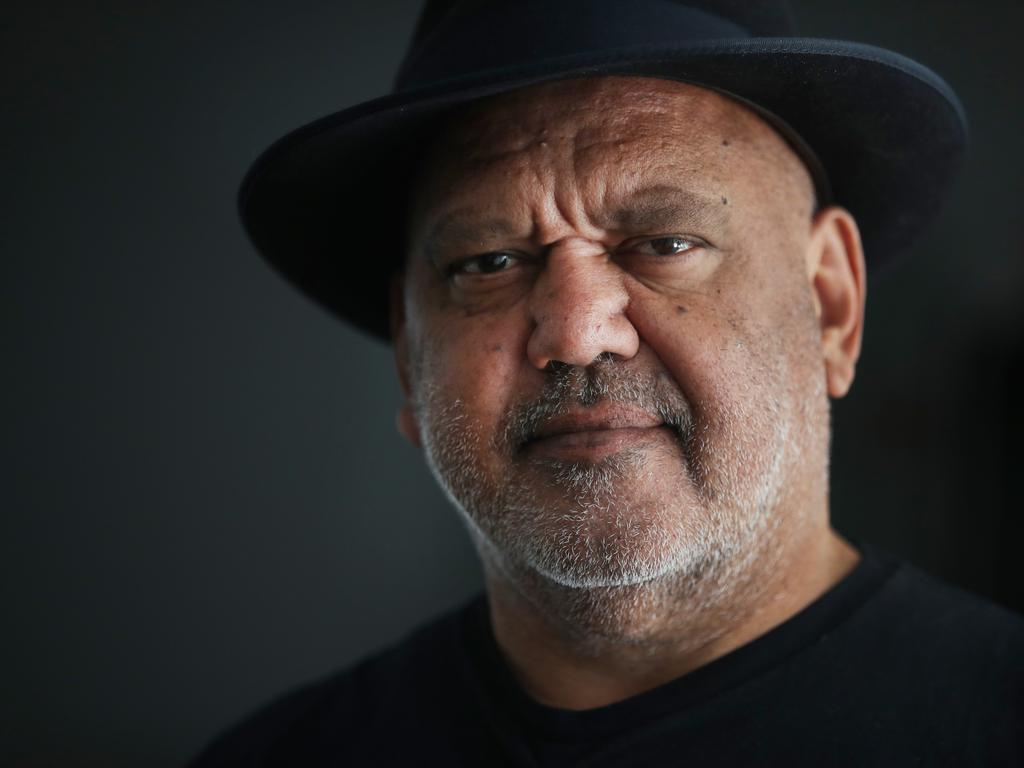

But the company’s co-chief executive, Dino Otranto, told The Australian a massive investment into new renewables and associated energy infrastructure was needed if Australia was going the grasp the opportunity to capitalise on a generational shift in the commodities market.

This opportunity encompassed both green iron – with Fortescue, chaired by billionaire founder Andrew Forrest, aiming to produce its first green metal from Pilbara ores within a year from its $US50m Christmas Creek pilot plant – and ammonia, which Fortescue said China had indicated would be an important feedstock for its power plants.

The iron ore miner and energy developer reported on Wednesday that its Fortescue Energy division lost $US659m in the 2024 financial year, which the company capped off with an announcement in July that it would cut 700 jobs across the broader business and scale back its green hydrogen ambitions.

But Mr Otranto said on Wednesday that Fortescue was still firmly committed to the green opportunity, and Australia had the chance to position itself to benefit from the next commodities boom, which would be focused on products such as green iron and ammonia.

“We will show the world that it is possible to make green iron metal – 95 per cent-plus pig iron that is in granules out of Pilbara-based iron ore with hydrogen as a reducing agent, derived from the sun and, in the future, the wind,’’ Mr Otranto said.

“So within a year, you’ll see us making further announcements around what the next stage of green iron development in Australia or around the world will look like.’’

Mr Otranto said the company was focused initially on proving up its green iron technology at the Christmas Creek plant, and would then scope sites around the world with abundant renewable energy sources.

“Our first step is proving the technology with the lower to mid-grade hematite out of the Pilbara, because that is the step that really hasn’t been done yet,’’ he said.

“Right now, the green iron projects around the world utilise a very high-grade feed, and there’s not many places around the world that actually produce that.

“So if you wind the clock forward and the trend of decarbonising our steel industry, there will be a real challenge for high-grade iron ore. “So the world needs to solve low to mid-grade iron ore and for Australia, where we hold a pre-eminent position in this space, we see endless opportunities to develop a green iron metal industry here in Australia.’’

Fortescue Energy co-chief executive Mark Hutchinson told The Australian on Wednesday that green iron plants would gravitate to areas with abundant and cheap renewable energy, which Australia currently lacked at the necessary scale.

Mr Hutchinson said the Pilbara was blessed with good sun and wind resources, but more investment was needed.

“The bit that we lack right now is the capital investment and getting the cost down,’’ he said.

“The most important thing for Australia is to get the power price down.

“And it’s not an equipment issue, it’s an installation issue, an operational issue, and that’s really the big thing we’ve got to solve as a country, because we have the resources, it’s just too expensive.’’

Mr Otranto added that power “unlocks everything’’, pointing to the historic establishment of the Whyalla and Newcastle steel operations on the back of coal supplies. He said the company was “doubling down on green iron’’, with a recent visit to China demonstrating to the company’s management that the green shift was going to present a huge opportunity, which was “much, much higher than we expected’’.

“When I was there a few weeks ago, the Chinese government made an announcement that 10 per cent of all coal-fired boiler feedstock will be ammonia,’’ he said. “And if you do the numbers, China burns two billion tonnes of thermal coal a year, 10 per cent of that by mass is 300,000 tons of ammonia.

“That’s nearly 50 million tonnes of hydrogen to get to that ammonia amount. So you just have to look at the actual investment in transforming a huge industry like that, and the train has definitely left the station.’’

Fortescue Energy this year is focused on four main projects: its 80MW Arizona hydrogen project on which it is expected to start construction this calendar year with production set for 2026; its 300MW Holmaneset green ammonia project in Norway targeted to start construction in 2025; its Pecem green hydrogen project in Brazil for which the design process has started, and; the Gladstone PEM50 project, which is a two-stage 50MW green hydrogen project that will operate alongside the company’s Gladstone electrolyser manufacturing plant.

Mr Hutchinson said the company would look to sell down stakes in those projects as they progressed. Fortescue Energy is expected to spend about $US700m on operations and $US500m on capital expenditure in the current financial year.

Earnings

On the earnings front, Mr Otranto said Fortescue delivered its third-best result to date, with underlying profit after tax of $US5.7bn, up 3 per cent.

Revenue rose 8 per cent to $US18.2bn, with the company receiving $US103 a tonne for its ore, also up 8 per cent.

The result was a miss on consensus profit estimates of $US6.12bn, while revenue was up 8 per cent at $US18.2bn, in line with market expectations.

Iron ore guidance for the current year is for shipments of 190-200 million tonnes, compared with 191.6 million tonnes in the 2024 financial year.

The company is expecting its cost for hematite production to come in at $US18.50-$US19.75 a tonne, up from $US18.24 for 2024.

Mr Otranto said it was another year of “outstanding” performance.

“We celebrated a number of significant milestones including first ore from the Flying Fish and Hall Hub deposits as well as the commissioning of our gaseous and liquid hydrogen plant which is the largest of its kind on a mine site in Australia,” he said.

Hydrogen from that plant will be used in the Christmas Creek green metals plant.

Fortescue said it had net debt of $US500m at the end of the financial year, with capital expenditure at Fortescue Metals expected to be $US3.2bn-$US3.8bn.

Dividends

Fortescue will pay a dividend of 89c a share on September 27, down from $1 for the same period last year. Total dividends for the full year were $1.97, up 13 per cent.

Andrew and Nicola Forrest, whose Tattarang investment vehicle owns 36.7 per cent of Fortescue, will be paid a touch over $1bn in final dividends, taking their haul for the year to $2.2bn.

The company’s financial reports also showed former chief executive Fiona Hick, who resigned about this time last year after just six months with the company, received a $2.1m golden handshake, which fell to $1.83m after adjustments in incentive payments.

Dr Forrest’s remuneration came in at zero, but he did receive $9035 in non-monetary benefits. Mr Otranto and Mr Hutchinson were paid $4.1m and $5m respectively for the year.

UBS said the earnings result was “a solid finish to FY24, despite key earnings metrics falling slightly short of expectations’’.

More Coverage

Originally published as Fortescue is guiding a modest uplift in shipments as energy arm books large loss