How Aussie company MCi Carbon will help turn CO2 into house bricks to help reduce carbon emissions

In what could be a global game-changer, an Aussie tech company is one step closer to removing carbon dioxide from the atmosphere - and locking it away in housebricks.

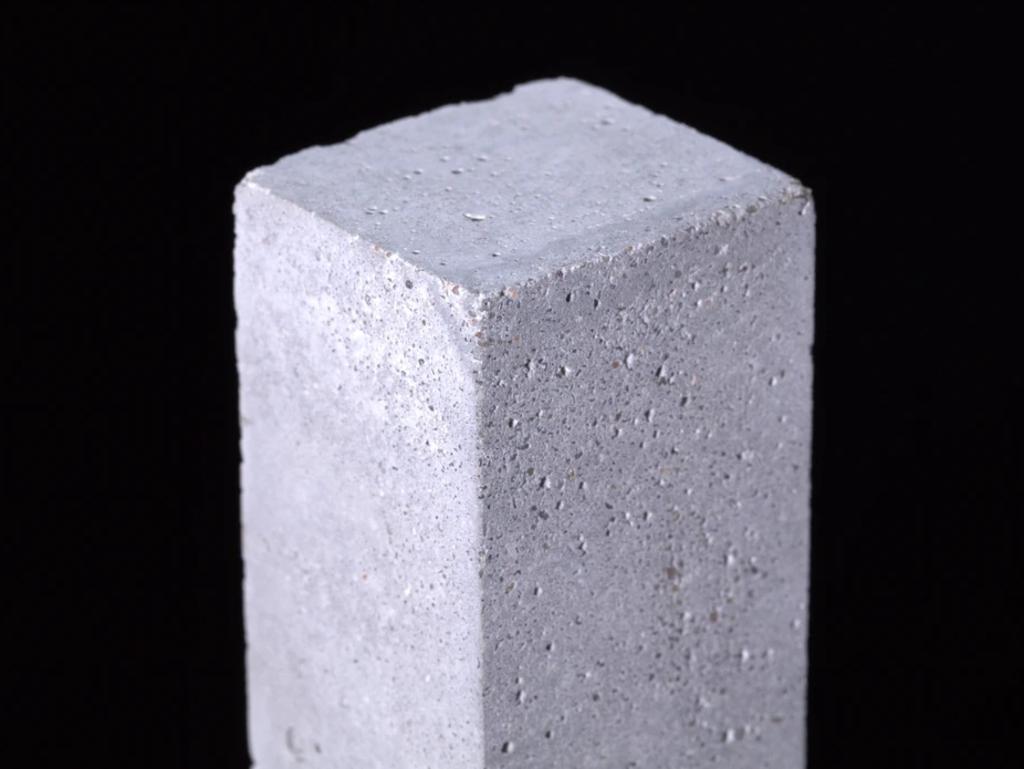

Very few things in life are as reliable as bricks. Solid, supporting and ultra-low-maintenance, they last pretty much forever, and behave in very predictable ways.

Humankind has been making them for thousands of years.

But now an Aussie company is seeking to remake the brick and other building materials as a handy receptacle for storing carbon dioxide, the invisible greenhouse gas piling up in the atmosphere at an ever-increasing volume, leading to runaway global warming.

MCi Carbon’s new facility at Orica’s Kooragang site in Newcastle will take trapped carbon dioxide (CO2) and turn it into raw carbonate materials, which will then in turn be used by other companies to create bricks, cement, plasterboard and related building products.

A foundation stone for the facility was laid on Wednesday, with Climate Change and Energy Minister Chris Bowen commending MCi for “reducing carbon emissions in our buildings, as well as storing carbon in ways that aren’t in our atmosphere”

The facility was an example of decarbonisation creating “good-paying, highly-skilled jobs,” Mr Bowen said.

The technology has already generated massive interest worldwide at events such as the COP26 conference in Glasgow, and the World Economic Forum in Davos, because of its breakthrough potential to bring down emissions in sectors where such solutions don’t currently exist, such as mining and heavy industry.

MCi Carbon chief operating officer Sophia Hamblin Wang said once the facility was fully operational (expected to be in early 2025), for every one ton of building material created, they would be stopping 300 kilograms of CO2 going into the atmosphere.

As a whole, the company is aiming to capture one billion tonnes of CO2 by 2040, using its carbonation processes to help create products for the built environment.

“The scaling up takes time. We’re running as fast as we can,” Ms Hamblin Wang said.

The Newcastle facility will be like a “Swiss army knife of mineral carbonation,” she said.

“We can take a variety of inputs and a variety of different flue gases and create a wide variety of output materials – or inputs into things like cements, plasterboards, drywall, paper, laundry detergents … you name it.”

The company’s chief executive officer Marcus Dawe said they would be using CO2 that Orica was already capturing while making ammonia.

He stressed the pilot nature of the project, saying the initial reduction in emissions for Orica would be “quite small” but the potential of the technology was massive. It could one day lock away more than 10 per cent of global CO2 emissions, he said.

“Every ton of CO2 is causing climate change. That was the IPCC’s [International Panel on Climate Change] first statement in their last big report,” Mr Dawe said.

Construction of the facility – named “Myrtle” as a nod to the fact that trees also store carbon dioxide – was enabled in part by $14.6m awarded by the former government in 2021 from its Carbon Capture, Utilisation and Storage Development Fund.

Carbon Capture and Storage (CCS) has long been questioned by critics, who say it is expensive and inefficient, with even the International Energy Agency cautioning against relying on it too heavily.

But Carbon Capture and Utilisation (CCU) – of which the Myrtle plant is an example – had “become a lot more prominent in the last couple of years,” Ms Hamblin Wang said.

More Coverage

Originally published as How Aussie company MCi Carbon will help turn CO2 into house bricks to help reduce carbon emissions