Sydney start-up Paco Industries has developed a process to infinitely recycle PET plastics

It could be the holy grail of plastic recycling; a Sydney start-up has found a way to ‘infinitely’ recycle plastic used for our food containers.

Business

Don't miss out on the headlines from Business. Followed categories will be added to My News.

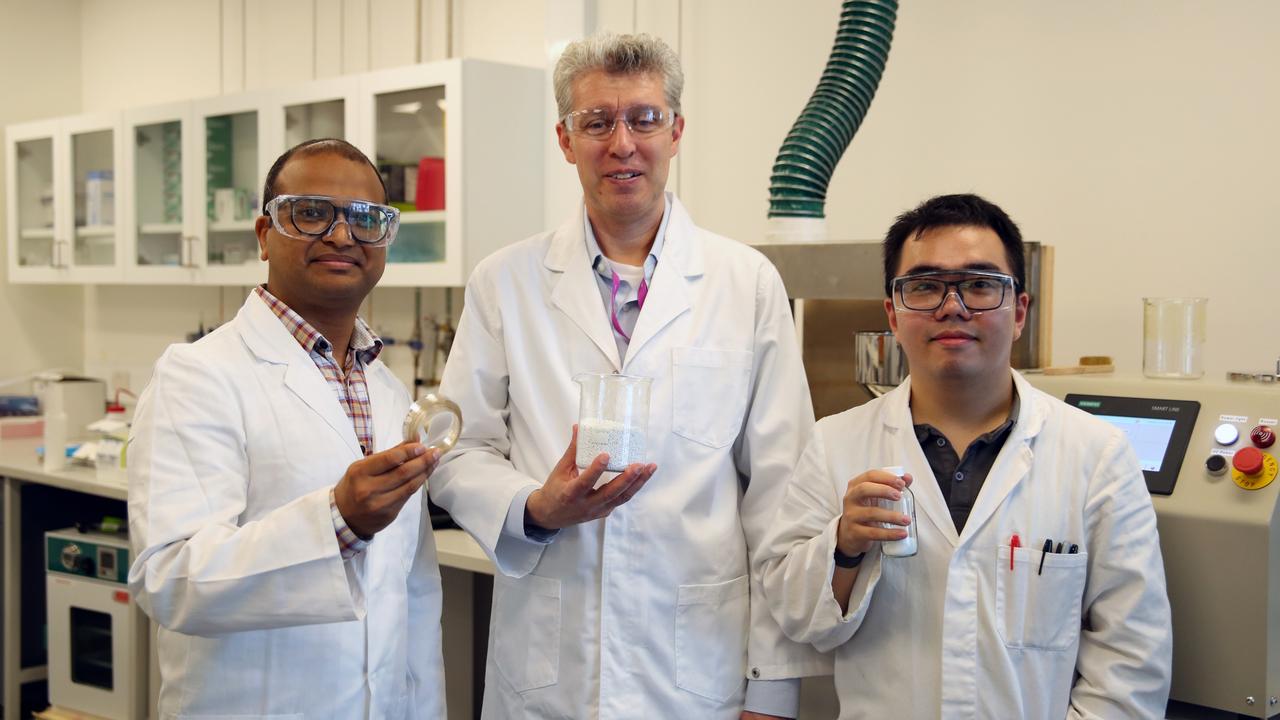

An Australian start-up claims to have cracked the code to infinite recycling after it developed a solvent that allows contaminated plastic to be used repeatedly – a move that could potentially boost its revenue by $100m a year.

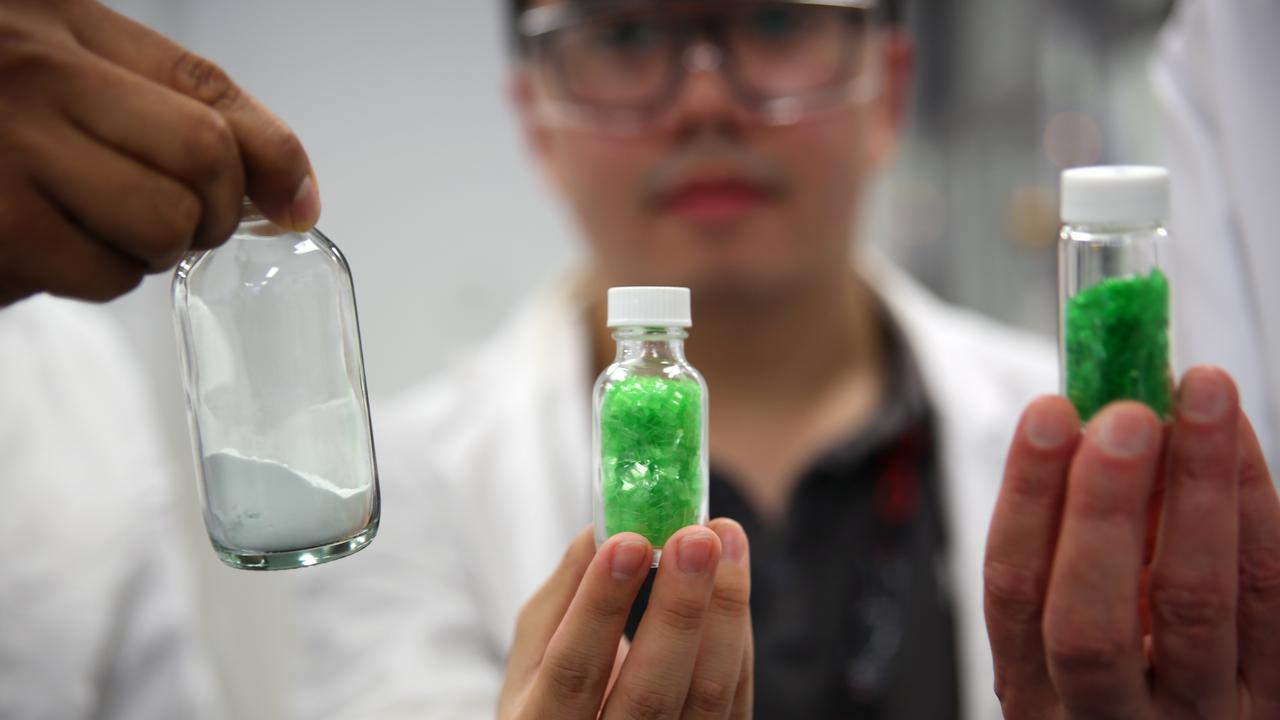

Paco Industries’ discovery has overcome one of the biggest barriers to the repeated recycling of polyethylene terephthalate plastic (PET), which degrades each time it is reprocessed.

It has caught the attention of food giant Arnott’s and speciality coffee roaster Pablo & Rusty’s, which have agreed to use Paco’s technology if it can be delivered at scale.

Paco Industries has the capacity to produce 1000 tonnes of plastic per year at its base at the University of New South Wales, but the start-up is seeking a larger facility and aims to reach between 20,000 and 30,000 tonnes.

That figure would be the equivalent of 5 per cent of the Australia’s plastic production market, and equate to about $100m in revenue. This compares with Paco Industries’ current market value of $23m.

The company’s head of commercial, Steven Commerford, said most plastics end up in landfill despite the City of Sydney claiming 84 to 96 per cent of items put in recycle bins were reprocessed.

“Most of the waste PET that goes into our yellow bins unfortunately finds its way to landfill and the main reason for that is it is contaminated with organic or inorganic material,” he said.

Mr Commerford said Paco’s solvent removes scraps from PET without it degrading.

“While no one has lived for an infinite number of years, what we’ve done is found a way that we can recycle PET without disrupting the form of chain,” he said.

“Typically plastic is a downward spiral, much like paper recycling, so the fibres or the chains become shorter and shorter over time.

“(With our solvent) we’re able to recycle at the same level and it means that we’re able to essentially take food-grade PET plastic and make it into food-grade PET plastic again.”

Paco Industries is the commercialisation arm of FP Paradigm – an impact investment fund.

It was set up just six months ago under a partnership with the Future Food Systems CRC and with UNSW, where Paco Industries operates and has access to food and plastic scientists.

Arnott’s has signed a memorandum of understanding to support Paco Industries’ further research and development. Coffee giant Pablo & Rusty has signed a similar MOU, and its chief executive, Abdullah Ramay, said it was logical for coffee companies to want to invest in the recycling space.

“Working with Paco Industries and UNSW over the last six months to address some of the packaging issues in not just coffee but the broader food and beverage market has led to some already promising developments,” he said. “It makes sense for us to be looking at new technologies as P & R has always been at the forefront of sustainability.”

Both the companies have signed with the intention of potentially using the plastic Paco Industries is able to create, if it reaches a viable commercial scale.

Australia’s recycling industry is a $19bn sector supplying more than 94,000 jobs, according to the Australian Council of Recycling.

Despite circular initiatives, the World Wildlife Fund Australia says plastic consumption has grown from 123kg per person in 2010 to 147kg per person in 2021. Of, that just 14 per cent is recycled. About 145,000 tonnes of plastic is not disposed of correctly and makes its way into the environment each year, according to WWF.

Paco Industries was not just developing a solution for contaminated plastic but it was also developing food waste sensors, which would help provide a solution for food close to expiry, Mr Commerford said.

“If you look at food waste in isolation, it’s probably the biggest contributor to CO2 emissions so we’re looking at how we can potentially re-purpose a used-by date system by using colour coding for consumers,” he said.

But much of the start-up’s focus for now would be on developing its solvent and its ability to ramp up production

Aside from finding a new facility to set up in, the start-up was also seeking ways to reduce the cost of recycling plastic.

“Unfortunately, right now recycled material is more expensive than virgin material, and that’s the major problem with our recycling system,” Mr Commerford said.

“The point of this is to close the loop completely for PET plastic and the reason you can now do that is because you can make a like for like product (by using this solvent). However it will come at a cost and whether consumers or brands take on that costs is another question.”

More Coverage

Originally published as Sydney start-up Paco Industries has developed a process to infinitely recycle PET plastics