Cracking “silicon code” was first step and Altech has now improved it

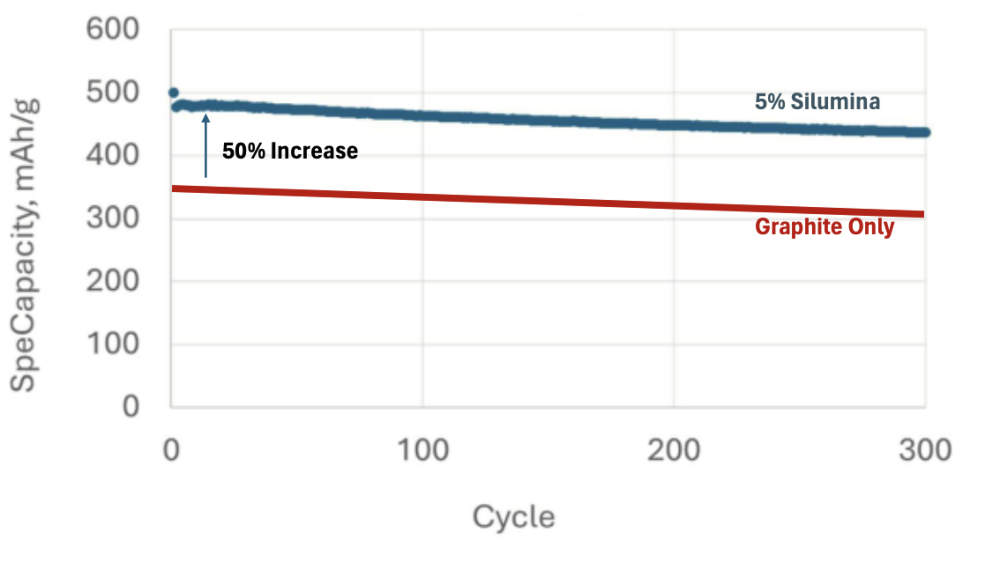

Altech’s latest Silumina Anode technological breakthrough has delivered a 50% capacity improvement in battery applications.

Stockhead

Don't miss out on the headlines from Stockhead. Followed categories will be added to My News.

Altech Batteries’ further development of its Silumina Anodes technology increases lithium-ion battery capacity and lifespan

Development involves spherisation of coated silicon particles that are distributed to reduce impact of swelling

Optimised silicon content increased to 5%, delivering 50% capacity performance improvement in battery applications

Special Report: Altech Batteries has unveiled a potentially game-changing technological development under its Silumina Anodes project that increases lithium-ion battery capacity and lifespan.

The development involves the spherisation of alumina coated silicon particles, applying additional coatings to the spherical structures and distributing the particles within the voids of graphite to further reduce the impact of swelling.

This has allowed Altech Batteries (ASX:ATC) to increase the optimised silicon content to 5%, delivering a 50% capacity performance improvement in battery applications.

It builds on the company’s initial success in addressing the issues faced in using silicon in lithium-ion batteries such as particle swelling, first-cycle capacity loss of up to 50% and rapid battery degradation, which far outstripped the benefits such as potentially increasing energy capacity as silicon can hold up to 10 times more lithium ions than graphite.

ATC’s successful initial approach involved coating individual silicon particles with a nanolayer of alumina to reduce expansion and mitigate first-cycle loss.

“The next generation of our development, leveraging spherisation technology, has successfully addressed the long-standing challenges of silicon—namely swelling and rapid degradation,” managing director Iggy Tan said.

“We've achieved a battery with 50% higher energy density and enhanced cycle life, all with a modest addition of silicon. Our proprietary alumina-coated, spherical silicon particles represent a breakthrough in battery anode materials.”

Pilot plant operating

Adding further to the new development, the company has also successfully produced coating silicon products at its pilot plant at Dock 3 in Saxony, Germany.

The commissioning process had presented a number of technical hurdles relating to equipment delivery delays, material supply, poor flowability and handling difficulties of the ultra-fine silicon powders used in the process.

These powders had tended to cause hang-ups and blockages within the system, complicating consistent material movement and process stability.

However, ATC was able to solve these issues through a combination of engineering adjustments and process optimisations.

Its pilot plant is now operational and has produced high-quality coated silicon particles for evaluation and testing by potential customers.

“Production at our pilot plant in Saxony marks a significant milestone, and we are actively engaging with potential customers for evaluation,” Tan added.

“This progress places Altech at the forefront of next-generation battery technology as we move toward commercialisation.”

This article was developed in collaboration with Altech Batteries, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Originally published as Cracking “silicon code” was first step and Altech has now improved it