Andromeda Metals paves way for 4N HPA production with testing breakthrough

Andromeda Metals is starting a scoping study into producing high purity alumina after successful laboratory tests.

Stockhead

Don't miss out on the headlines from Stockhead. Followed categories will be added to My News.

Andromeda Metals’ laboratory-scale testing produces 4N HPA using refined kaolin sourced from its Great White Project

Result validates Andromeda’s novel flowsheet, which is expected to be more cost-effective and less carbon intensive than traditional HPA production methods

While the company remains focused on developing GWP, it will start scoping study into HPA production

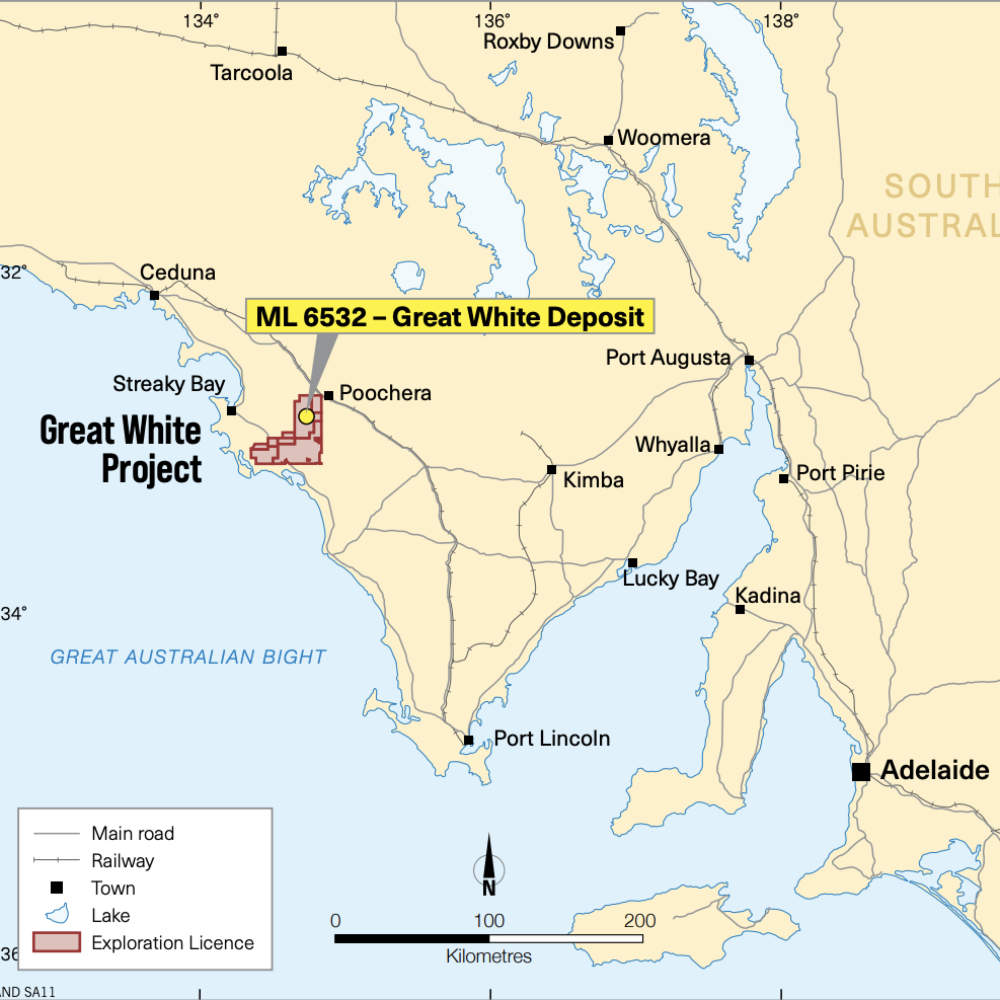

Special Report: Andromeda Metals has validated its novel flow sheet after laboratory-scale test work produced high purity alumina (HPA) using refined kaolin from its Great White Project (GWP) in South Australia.

Analysis of the produced HPA confirmed it has a purity of 99.9985%, well above the 99.99% purity required to be considered 4N HPA for use in lithium-ion batteries as a battery separator, as well as the production of synthetic sapphire glass and LEDs.

This validates Andromeda Metals’ (ASX:ADN) novel process flowsheet developed over seven years of investigation, research and metallurgical testing, and is expected to be significantly more cost-effective and less carbon intensive than other reported processes.

Being able to produce 4N HPA from kaolin is expected to provide significant cost and carbon emission advantages over the current dominant method of producing the critical mineral through synthesising aluminium alkoxide from high-cost aluminium metal.

The cost advantage also comes as demand for HPA is expected to outstrip global supply by 45% by 2028.

“Whilst Andromeda’s primary focus remains the development of the Great White Project, the production of HPA is a high-value and complementary opportunity,” ADN acting chief executive officer Sarah Clarke said.

"This latest test work validates our novel flowsheet, showing our Great White CRM product from the Great White Project can be used to produce HPA at an impressive 99.9985% purity.”

She said this demonstrated the potential to expand the company’s product portfolio in the future to include a value-added critical mineral while underpinning its confidence in progressing HPA production to the next stage of development.

“The promise of producing HPA – a high-value, in-demand product – at lower cost and reduced carbon intensity compared to established processes should be highly attractive to any manufacturers using HPA in their products,” Clarke added.

HPA production

ADN's novel flowsheet uses established metallurgical unit operations to refine the aluminium oxide from kaolin.

Importantly, it does not require hydrochloric acid crystallisation of aluminium chloride hexahydrate nor re-leaching using acid at high temperatures and pressures to achieve high purity levels.

Likewise, it does not need the product to be calcined at temperatures typically above 1250°C to remove chlorides.

Rather, the company’s process produces HPA that can be calcined starting at 700°C while providing a wide range of product forms, from amorphous to crystalline.

It is also flexible enough to produce HPA that’s tailor made to suit specific customer and application requirements.

Testing has indicated that each tonne of ADN 4N HPA can be produced with less than 4t of CO2 emitted, 68% lower than the 12.3t produced using the traditional aluminium alkoxide process.

This can be further reduced by leveraging South Australia’s leadership in generating more than 70% of its electricity from renewable sources.

With these results in hand, the company intends to complete a scoping study and engage with HPA customers to assist in developing the product form, morphology and crystalline structure to suit their specific use and applications.

It will also investigate government funding opportunities.

Great White Project

ADN's GWP is backed by 15.1Mt in high-grade ore reserves, enough to fuel a 28-year mine life.

A 2023 bankable feasibility study estimated capex at $194m for a three-stage development that could supply up to 330,000 wet metric tonnes of product per annum, generating an NPV and IRR of $763m and 43% respectively.

The company has already lined up customers for 100% of the capacity of the Stage 1A+ development, which will produce Great White CRM™ (a refined, dried and bagged product) and Great White KCM™90 (a semi-refined, high-quality kaolin concentrate).

All key approvals are in place and the company is in exclusive negotiations for a $75m debt facility that will underpin the stage 1A+ development, which is expected to cost about $84m.

This article was developed in collaboration with Andromeda Metals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Originally published as Andromeda Metals paves way for 4N HPA production with testing breakthrough