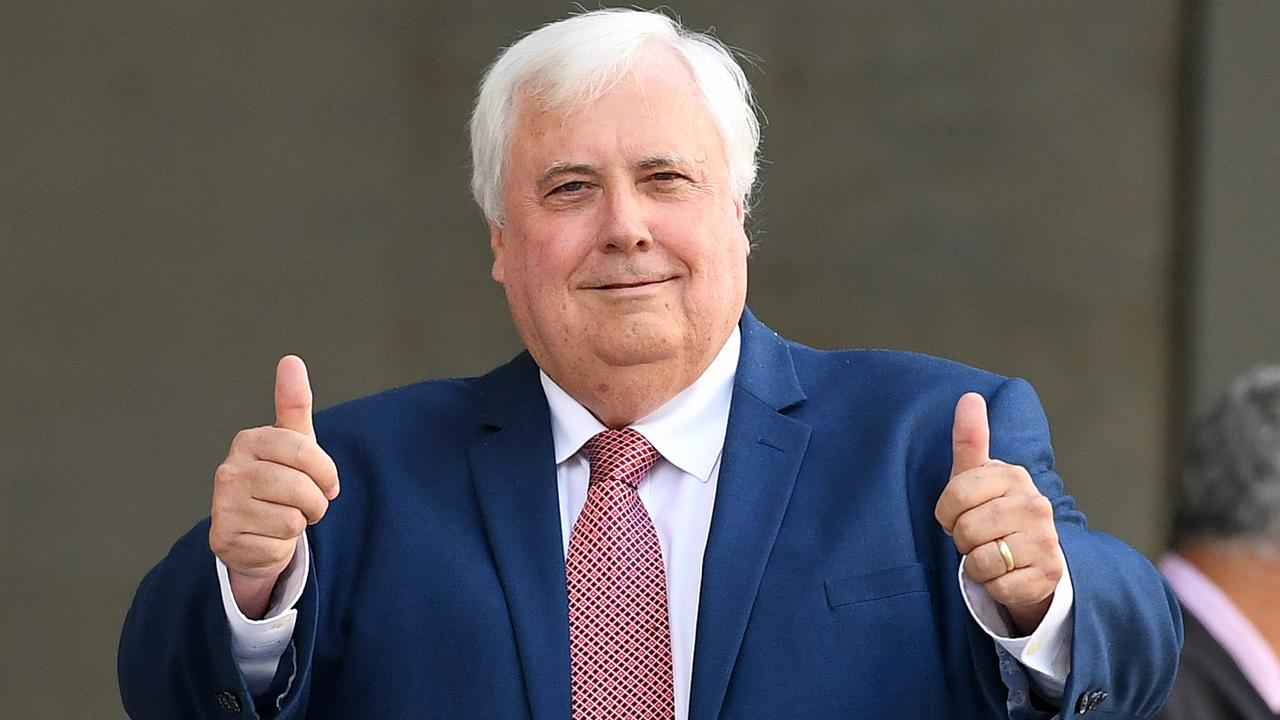

Explosion rocks nickel refinery as Palmer faces $30m repair bill

Clive Palmer’s Queensland Nickel is facing repair and maintenance costs of more than $30m.

Administrators at Clive Palmer’s Queensland Nickel are trawling through a daunting list of overdue maintenance requests engineers say could expose the company to costs of more than $30 million and ultimately decide the future of the troubled Yabulu refinery.

An explosion in one of the refinery’s 12 nickel roasters early yesterday has fuelled speculation that mass sackings had translated into a drop in safety standards.

While it soon became clear the minor explosion was the result of gas build up in a roaster that had been out of use for a number of weeks due to declining nickel production, leaked documents revealed the refinery remained exposed to potentially greater safety risks.

The documents, provided to administrators FTI Consulting and viewed by The Australian, outlined a number of outstanding workplace health and safety issues to be addressed with varying levels of urgency at an estimated starting price of $30m.

Top priorities included, but were not limited to, the removal of roof panels allegedly containing asbestos from the main workshop at the Yabulu refinery.

Information provided to the company said quotes to rectify the problem had come back at $130,000 and were not pursued.

It was also claimed that the fuel pipeline between the Townsville port and the refinery had not undergone a routine inspection — known as “pigging” and said to generate a “complete picture of the pipe” — since 2012.

A source told The Australian a leak had been found in a section of pipe within Townsville city a number of years before, but that requests for maintenance checks had been rejected.

The source said another leak could spell environmental disaster and inspections, to be taken in line with the licensing agreement the company holds with Queensland Rail, were critical.

The Australian can also reveal one of the lines, which provides much of the ammonia needed to remove the nickel from the ore, had been broken for more than a month, meaning up to five tonnes of the commodity was being “thrown away” at any given time, potentially costing the refinery about $20,000 a day.

The need for another cell wall lift on the refinery’s tailings dam, at a projected cost of $10m, was also flagged. The source said it would be up to FTI to understand the refinery’s “risk profile” and consider whether it was prepared to continue to operate on that basis.

It is believed immediate costs could reach about $30m, stretching to $100m within a year and up to $300m to safeguard the company’s future. A spokesman for FTI Consulting said the contents of the documents provided were not in dispute and, while there was “clearly work that needs to be done”, the company had been assured the refinery was currently operating safely and would continue to do so until a second creditors meeting was held.

They said a planned shut down for one week at the end of this month, due to declining nickel production, would provide an opportunity for urgent maintenance works to be carried out.