Future frigates yard in Australia aims for global ranking in defence and shipbuilding

Future frigates builder ASC Shipbuilding says it can have one of the most efficient shipyards in the world, in Adelaide.

Other naval shipbuilding activities have engendered their share of early controversy, but the $35bn program to construct nine Hunter-class frigates for the Royal Australian Navy has got away to a remarkably smooth start.

Fifteen months after the selection of an Australianised version of the BAE Systems (BAES) Type 26 Global Combat Ship to replace the RAN’s eight Anzac-class frigates under Project Sea 5000, a head contract has been signed, the first major design review has been successfully completed, prototyping preparations are under way, and construction of a purpose-built shipyard is proceeding apace.

The head contract incorporates allowable profit margins, other terms and conditions, the acquisition of long lead material, and the detailed scope for design and engineering work necessary to allow prototyping to begin in 2020 and to ensure steel is cut on the first ship in 2022.

Separately, the peppercorn sale of commonwealth-owned ASC Shipbuilding (ASCS) to BAES Australia for at least the duration of the Hunter-class build has made that company fully accountable for the ships’ delivery from the new $530m Osborne South facility.

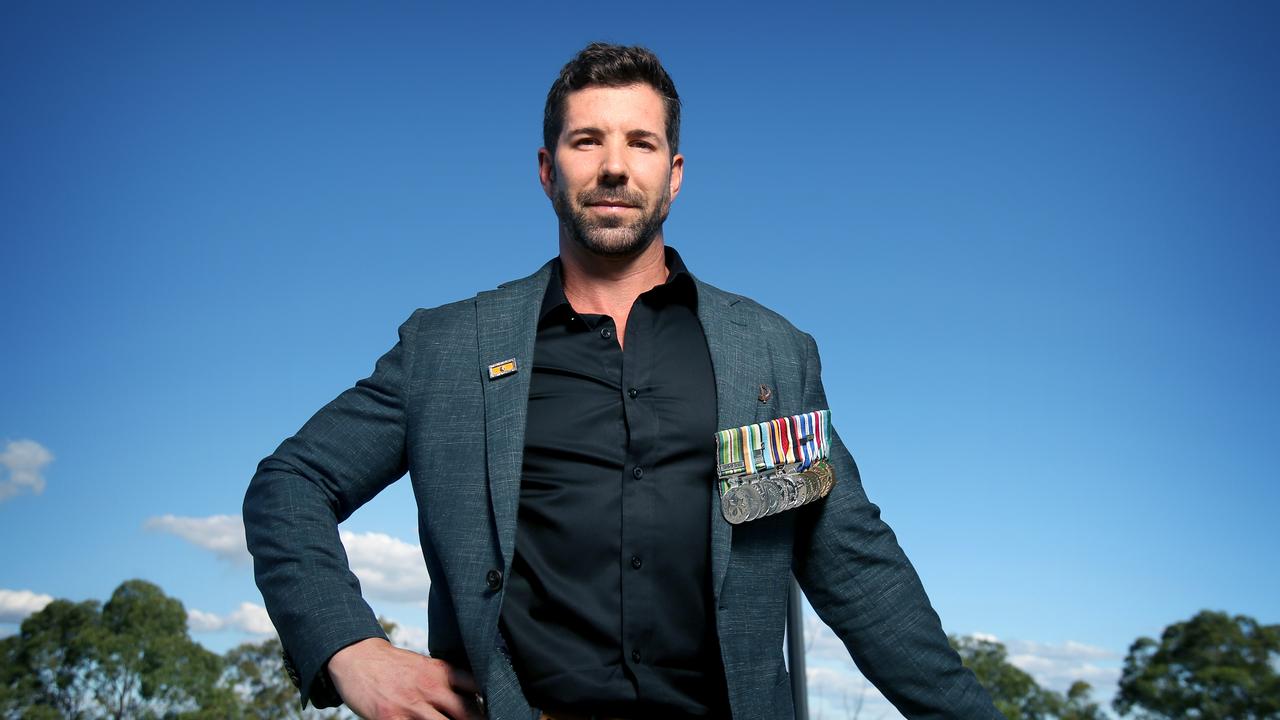

“In late August we came out of the systems readiness requirement, our first big design review, with 42 recommendations,” ASCS managing director Craig Lockhart says. “The good news is there were no surprises,’’ he says. “All of those recommendations were closed by late September, and they were all based on things on which we and the commonwealth had already been working,” Lockhart says.

“Our next big review is the systems definition review in November 2020, and that looks to a mature understanding of the combat-management system with respect to its integration with the platform.”

Of the 12 zones into which the Type 26 reference ship under construction in Scotland is divided for design purposes, several of the nine which are now mature for British requirements involve ‘‘fight and flight’’ activities requiring complex design changes to accommodate Australian-specific systems. These changes are being progressed in Adelaide.

“There’s a new hangar structure for the MH-60R naval combat helicopter at the stern and changes further forward regarding the Harpoon anti-ship missile arrangements. The ships are fitted ‘for and not with’ because Harpoon is becoming an obsolete system and we’ve got design work around how we do that,” Lockhart says.

“And the Ceafar2 active phased array radar, which is the visible difference between the Australian and UK ships, is a big, heavy, powerful piece of kit requiring a new mast,’’ he says.

“We’ve got to make sure the mast structure doesn’t add to stability issues. Ceafar2 is also much more power-demanding than its UK equivalent and we have to ensure that when it’s operating at peak power and peak capability, the rest of the ship can not only cope with it but can also manage the power distribution such that all systems work at 100 per cent capability 100 per cent of the time.”

Other Australian-specific equipment includes the Aegis combat management system, Standard SM-2 Block 111A/B and Evolved SeaSparrow anti-air missiles, a new tactical interface, and the Nulka anti-missile decoy.

The new shipyard, designed by Danish specialists Odense Maritime Technology and leased to ASCS by commonwealth-owned Australian Naval Infrastructure, comprises a 50m-high block outfitting and ship erection hall, a 28m-high block assembly hall, and a steel fabrication and unit workshop together with a blast and paint facility. Concrete floors are layered up to 1.5m thick.

The unit-fabrication workshop and block assembly hall are close to completion, while the roof structure for the main assembly hall should be in place before the end of this year.

Although ACSC will not move into the South Osborne facility until July 2020, later this year it will begin releasing expression-of-interest requests to industry to prepare its supply chain for the start of prototyping in December 2020.

This will involve the construction of five prototype hull blocks of increasing complexity to test shipyard skills, processes and equipment, before work on the initial production block for the Hunter-class first-of-type begins in December 2022. Man-hour and other build-performance targets per ship have been replaced by a focus on shipyard efficiency from end to end, Lockhart says.

“I would hope there will be no cost premium for construction in Australia. Our intention is to set up this shipyard and this company as one of the most efficient and effective shipyards in the world.

“Part of my job is to make sure we have that sovereign capability to design and build and bid for other classes of ship somewhere in the future, and in order to do that we’ve got to be competitive.”

The first of the Hunter class should be launched in 2027-28 and enter service inside 2029-31. The ships are initially planned to be built on a two-year interval, meaning the ninth and last ship would not enter service until 2044-46, but this drumbeat could be accelerated depending on skills, capability and budget, Lockhart says.

ASCS’ current resources are being used by Luerssen Shipbuilders to produce the first two of 12 Arafura-class offshore patrol vessels for the RAN, and Lockhart confirms that work is “exactly where we said we’re going to be”.