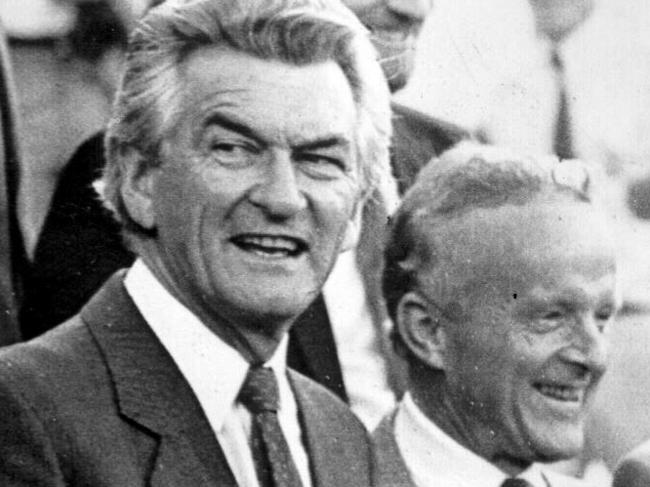

Treasurer Jim Chalmers should follow Bob Hawke lead on Made in Australia

Industry policy and priorities are shaped by the circumstances of the time, but some lessons and challenges are timeless.

It came as no surprise that polling showed support for the Future Made in Australia project. How could you not support the sentiment? The challenge is to translate it into realisable goals, against a backdrop of manufacturing in decline and a cost-of-living crisis.

It was a mistake to launch Made in Australia with the commitment to manufacture solar panels. It raised immediate concerns. So, too, the revelations this week about the processes leading to the funding of US-based PsiQuantum.

Jim Chalmers should use the budget to clarify the project’s purpose, goals, framework and funding guidelines.

Anthony Albanese assures us it’s not about protectionism but “supporting industries which will be able to stand on their own two feet”. Who could disagree? If that’s the bottom line, what’s the defence of the $1bn to manufacture solar panels?

It certainly couldn’t meet the Treasurer’s test of being competitive and productive. A global glut of stockpiled Chinese panels, at rock-bottom prices, has led to plant closures and job losses across Europe and Britain. Alternative supply chains can be created with India and the US. The market will decide the success of any new domestic company wanting to assemble modules using imported components.

Labor’s vision of being a renewable energy superpower isn’t widely accepted. That’s understandable given the government can’t guarantee power for industry all day, every day, or assure households of its availability at the flick of a switch. Lesson No.1 is that manufacturing’s success will always be inextricably linked to reliable and affordable baseload power. Renewables won’t suffice.

Future challenges can’t be underestimated. Recently, Qenos, a key plastics manufacturing company, collapsed. Tritium, an advanced manufacturing company, folded too. It had been a showcase for the renewables transition. Politicians were regular visitors, promoting its fast chargers for electric vehicles

The fate of manufacturing has been a perennial issue for Labor. A recent analysis, based on census data, shows an accelerating decline in recent times.

Back in the Hawke-Keating era, manufacturing accounted for about 18 per cent of the workforce. Between 2006 and 2021, it declined from 10.7 per cent of the workforce to 6.2 per cent. This fall was greater than for any other industry. In that 15 years, one in four manufacturing jobs disappeared, resulting in a total loss of around 250,000 jobs.

Industry policy and priorities are shaped by the circumstances of the time, but some lessons and challenges are timeless.

As soon as it was elected in 1983, the Hawke government faced the urgent problem of averting the looming collapse of the steel industry. The first of minister John Button’s industry plans ensured its survival. Strict conditions were imposed in return for government support.

Targeted and temporary support, with clear objectives, has always been warranted.

Four decades later, steelmaking faces a new set of challenges. As a trade-exposed industry, now carrying a carbon impost, it competes in a challenging global environment. Reducing emissions in blast furnace production is a huge hurdle for a strategic and essential industry. It also employs thousands of workers and provides a substantial multiplier effect in the wider community.

A collaboration between BlueScope at Port Kembla and two of our largest iron ore producers, Rio Tinto and BHP, is attempting to find a possible pathway to low-carbon steel. It’s in line with the Treasurer’s objective of an orderly and sustainable path to net zero. As a first step, the pilot will explore the development of an iron-making electric smelting furnace. It will specifically use Pilbara’s iron ore as a feedstock.

If the trials are successful, it eventually could pave the way for a commercially viable alternative to blast furnace steelmaking. The benefits would be inestimable, as furnaces are used by 70 per cent of global steelmakers. This has never been understood by the virtue signallers. Their demands for “green” steel are totally divorced from the realities of integrated steelmaking.

The pioneering research of the Grattan Institute’s Start with Steel report, back in 2020, and the Clean and Mean publication by the John Curtin Research Centre along with the Australian Workers Union, provided early and valuable insights. Paying heed to solutions offered by those with first-hand experience avoids later regrets, as we found in the failure to reserve domestic gas.

If successful, this pilot will give impetus to emissions abatement in steelmaking and open opportunities for the iron ore industry to add value. This example shows the importance of securing the viability of existing industries, such as steel and aluminium, while exploring future possibilities.

The use of substantial funds from the public purse should be open to scrutiny and not hidden away in contracts deemed “commercial in confidence”.

The public’s right to know is a basic principle. Labor’s promise of accountability and transparency in government should mean rigorous and open processes from the start.

Jennie George is a former president of the ACTU and the former Labor member for Throsby.

To join the conversation, please log in. Don't have an account? Register

Join the conversation, you are commenting as Logout