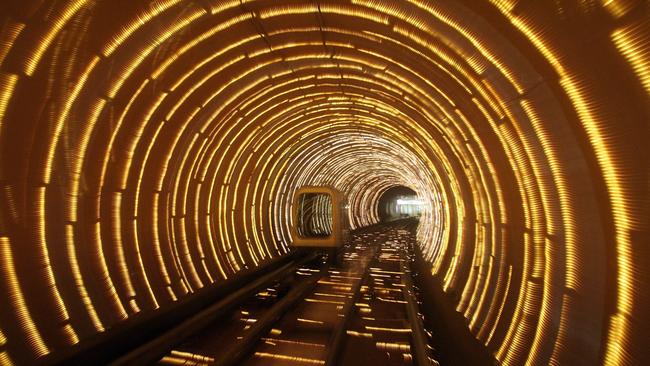

Shanghai Covid lockdown strains global supply chains

China’s exporters are bracing for delays as warehouse operations, transport and staffing are disrupted.

A lockdown in Shanghai marks another potential setback for China’s export machine, reigniting concerns over the risk of renewed disruption to global supply chains constrained by the pandemic and war in Ukraine.

Authorities imposed a two-stage lockdown on China’s most populous city on Monday, the latest reverberation from the country’s zero-tolerance Covid-19 strategy that is facing its toughest test yet from the highly contagious Omicron variant.

Tesla is suspending production at its car plant in Shanghai for four days, but chip maker Semiconductor Manufacturing International Corp, which has two fabrication plants in the city, is producing and operating as usual, a company representative said. Shanghai’s port remains open, but exporters are bracing for delays as the lockdowns hit warehouses, transport and staffing, a pattern experienced during similar targeted lockdowns such as the one in the southern city of Shenzhen.

Though China is getting better at keeping ports open and factories humming when restrictions tighten in response to rising caseloads, economists and executives say the repeated flare-ups and logistic headaches of navigating public health measures are weighing on industry, keeping up inflationary pressure on a world economy already struggling with surging prices.

“China is getting better at managing the shocks, but the shocks are getting bigger,” said Hui Shan, chief China economist at Goldman Sachs in Hong Kong.

A surge in coronavirus cases earlier this month prompted Chinese authorities to impose lockdowns and closures in chunks of the country, including manufacturing hubs such as Shenzhen and the city of Changchun in the northern province of Jilin.

Shanghai ordered citizens on the eastern side of the city to stay home on Monday and shut down public transport for four days while public health officials conduct a testing blitz. The lockdown is due to switch to the western half of the metropolis of about 25 million on April 1.

For now, the city’s port remains open as usual, according to operator Shanghai International Port Group. Essential workers and service providers such as medical staff, police and food delivery workers will still be allowed to move about provided they show a work pass.

Factories will be allowed to maintain operations under “closed-loop production”, authorities said, a system that involves staff working, living and staying within the factory campus.

But even with such measures, keeping the flow of goods moving from factory to port to customers overseas is tricky as the lockdown ensnares truckers, warehouses and other links in supply chains.

“Warehouses have shut down and transportation to and from the port has been disrupted,” said Zou Xiaodong, vice general manager at Shanghai Gangxian International Freight Forwarding.

Truck drivers are required to show a negative result from a coronavirus test taken within 48 hours if they want to enter the city. Some drivers are avoiding Shanghai altogether, fearful of ending up in quarantine.

“Many drivers worry that they can transport the goods to the port, but cannot return from the port because of the stringent pandemic restrictions,” said Mr Zou.

Even if factories can continue producing, with no one to pick up what they have manufactured “there is only so much that can be done before production slows down due to warehouses filling up”, said Cameron Johnson, head of APAC strategy at FAO Global, a strategic advisory firm.

To minimise delays, Kuehne+Nagel International, a global logistics operator based in Switzerland, has diverted some ships bound for Shanghai to the port at Ningbo, about 160km away, and airfreight to Zhengzhou, about 800km away, said Siew Loong Wong, president of Asia Pacific. He expected a challenging week or so as the lockdown plays out but that he was confident the disruption would be short term.

In imposing a limited lockdown while trying to keep the fallout for manufacturing and exporting to a minimum, Shanghai is following a playbook refined in Shenzhen, a southern technology hub that eased containment measures after a week of restrictions and mass testing.

A full lockdown to contain a Covid-19 outbreak in June last year shut Shenzhen port’s Yantian terminal for a month, causing a huge backlog of containers that snarled up ocean traffic and sent freight costs soaring.

This time around, the port stayed open and some employers instituted closed-loop systems to keep workers at or near the factory to keep production running.

Those moving goods across provincial boundaries must contend with a patchwork of health regulations. Truckers making a long journey often need to show test results more than once. Failure to have the right digital code for the right province leads to delays. Disinfecting trucks and cargo add hours to journey times.

The concern is the pressure on global supply chains won’t ease while Omicron outbreaks keep popping up. The disruption so far to the flow of goods isn’t huge. but “it slows it down when already there are quite a few bottlenecks to worry about”, said Craig Botham, chief China economist at Pantheon Macroeconomics.

The Wall Street Journal