Australia can compete with Korean, Japanese batteries, says Sicona Battery Technologies CEO Christiaan Jordaan

Australia could produce cost effective batteries on par with Korea and Japan, even with higher labour rates, but there’s a huge problem, says Sicona Battery Technologies boss.

Australia could make lithium-ion batteries that are better and more cost effective than counterparts in Japan and Korea but local manufacturers are not ambitious enough, says Sicona Battery Technologies co- co-founder and boss.

Chief executive Christiaan Jordaan says local lithium-ion mining companies would rather leave advanced manufacturing to countries in Asia than do it themselves. And the idea that Australia should not try to advance its standing in the minerals and batteries space is “nonsense” and Australians should “dream a little bigger”.

Mr Jordaan spoke exclusively to The Australian after delivering a submission to the National Battery Strategy Issues Paper.

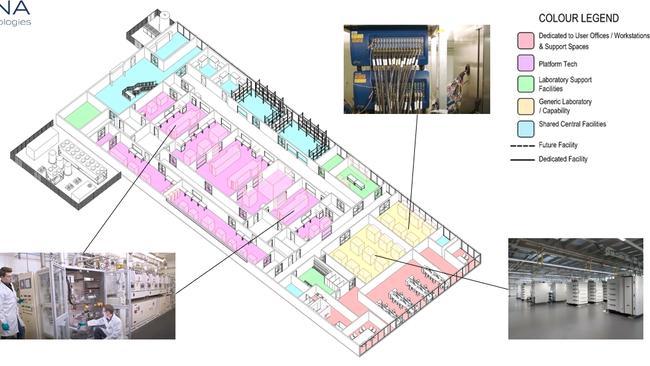

The comments arrive as Sicona Battery Technologies is looking to build two new major production facilities in NSW, with both plans expected to be put up just south of the start-up’s current headquarters in Wollongong.

In its submission, Sicona Battery Technologies has called for the nation to capitalise on the ability to produce refined chemicals such as lithium chemicals, cathode precursors and copper foils rather than export raw materials.

“If we vertically integrated all the critical minerals and materials we have in Australia through local cell manufacturing we could gain cost efficiencies above companies in Korea and Japan who are reliant on the imports of battery materials from Australia and China,” he said.

“If low-cost renewable energy then powered our facilities, even with potentially higher labour rates, I think overall we would end up with lower costs than other countries.”

Australia also needed to revolutionise its current university commercialisation models which “lack the capability and incentive to focus on spin out and start-up driven culture”.

Mr Jordaan said many Australian universities made it difficult for PHD students to turn their ideas and research into a business.

“Often universities push the person who came up with the idea into the corner with a very small equity stake while they bring in a CEO who has no skin in the game to run the business,” he said.

“Then they’ll partner with some vulture capital fund, they‘ll take a big chunk of equity and they’ll have the gall to describe that as being commercialisation success.”

Australian universities could learn from Silicon Valley-style commercialisation models seen at Stanford University which allow the inventor of the idea to take a larger stake. This would incentivise more people to take on research and produce healthier competition, Mr Jordaan said.

“Sicona was effectively birthed out of university-led research which we negotiated a transaction to acquire before the university took some equity in the company,” he said.

The submission also called on universities to develop a dedicated battery engineering and battery science degree.

“Battery engineering battery science needs to be taught at undergraduate level. Right now it’s a big challenge for companies like us to find the right talent,” he said.

“We need people with backgrounds in material science, chemistry and electrochemistry. And we’re going to need a big talent pool to fuel this drive for a more sustainable future.”

Sicona Battery Technologies has filed a grant application to the NSW government seeking funding to build a first-of-its-kind cell manufacturing plant in Shellharbour, NSW.

Mr Jordaan said this was the second time he had applied for the grant, with the last application becoming unsuccessful under the former government’s modern manufacturing initiative.

“We are more hopeful this time with the new Labor government and with the rights of the National Reconstruction Fund and the National battery strategy and a clearer understanding of the value that these type facilities create in Australia,” he said.

The start-up is also looking to build a battery materials processing plant near its current location in Wollongong, with its sights set on Port Kembla.

“The next stage for us would be to develop a small commercial scale manufacturing plant to produce the materials we need at scale,” he said.

The Port Kembla facility would have the capacity for a one gigawatt hour cell production plant.