Plotlogic's tech taking stock of ore

The frustration caused by the pandemic is particularly acute for Andrew Job, CEO of mining tech start-up Plotlogic.

The coronavirus crisis has caused frustration for businesses across the country, but for Andrew Job, chief executive of start-up mining technology Plotlogic, the frustration is particularly acute.

After nailing down a $3.9m round of angel investment funding late last year, which introduced big-name venture capital companies such as Baidu Ventures, DCVC, 8VC and Grids Capital to its register, Plotlogic is on the edge of launching its first commercial deal with mining giant BHP and is only waiting for the West Australian border to open so it can put its unique technology offering into the field on a commercial basis for the first time.

The product of research that began at the University of Queensland’s Smart Machines Group and the Mineral Research Institute of Western Australia, Plotlogic’s technology uses LIDAR, hyperspectral scanning and machine learning to map the face of a mining wall as the diggers work and build an ongoing picture of where the best ore sits as work is done.

Job says the technology, which has already passed field trials at coal mines in Queensland and iron ore mines in WA, can give mining geologists a far more detailed picture of where the best ore is within an operating mine, and where waste rock or damaging impurities may lie. “Understanding the boundary between ore material and waste material, or high-grade ore and low-grade ore, is really hard to do with traditional methods,” he says.

“So this allows us to pinpoint precision and make sure that what is being moved to waste is really waste, and we can make sure that everything that goes into ore stockpiles and the processing plant is the right ore and we’re not having excess waste material being processed.”

Field trials in Queensland coal mines showed the technology can also save miners from costly mistakes, according to Job.

“One of the clients we worked with last year had an issue with a clay material called ‘swelling clay’ — it effectively binds moisture and causes the entire processing plant to stop if they don’t know it’s coming,” he says.

“And visually it was hard to see which were swelling clays and the non-swelling clays and identify which was which.

“But our technology was able to map exactly where the swelling clays are and which materials contain them, and stop the plant stoppages.”

Rio Tinto, BHP and most other mining majors have identified “precision mining” as one of the keys to unlocking the next wave of productivity in the sector, to avoid the unnecessary movement of waste rock and help improve the quality of the ore fed into processing plants.

Both mining majors have run in-house programs to develop similar technology, but Job told The Australian the big miners Plotlogic had worked with had been just as happy to take on an Australian start-up as a partner.

“What we’ve been able to do is be very flexible and adaptable in our approach, and that agility that comes from being in a small start-up company,” he says.

“Working in closely with those big companies has allowed us to develop much more quickly than could be done by a traditional development program.”

BHP acting chief technology officer Rag Udd says the mining giant ha high hopes for the next round of work with Plotlogic.

“We work with a range of technology specialists across our business to find smarter ways of working, and this is a good example of bringing in outside expertise and applying new technology to get more out of our ore bodies and improve performance,” he says.

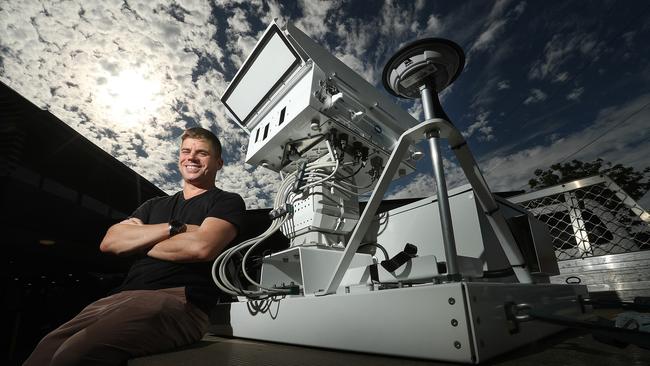

Plotlogic’s first trials used a portable scanning device on the back of a ute, or stood up looking across an open pit, but the ultimate goal, according to Job, is to produce a sensor that can be mounted on the top of every digger, drilling machine, truck or dragline to build up a working picture of any deposit as work continues.

Job, a 20-year industry veteran who left a job running one of Anglo American’s Queensland coal operations to found Plotlogic, says successful field trials with BHP’s iron ore and coal divisions, AngloGold Ashanti and Citic Pacific Mining over the past three years have helped refine the company’s technology.

Despite being still only on the edge of commercialising the technology, the company is now fielding inquiries from miners across the globe, he says.

Plotlogic’s first commercial deal with BHP is at its Yandi mine in the Pilbara, to see if its technology can be used to eke out the last remaining value from the mine in its last few years of operation, after nearly 30 years as one of BHP’s best Pilbara money spinners.

But for now the scanner destined for Yandi is stuck in the company’s Queensland workshop, waiting for the borders to open, much to Job’s annoyance.

“We expect the technology will be successful — we’ve bet the house on it.

“We just want to get over there and get it working,” he says.

To join the conversation, please log in. Don't have an account? Register

Join the conversation, you are commenting as Logout