Far north canegrowers fighting to save their industry

A small Far North Queensland sugar town is fighting for its life, with fears its biggest employer will be shut down by year’s end.

As the winds of foreign ownership and global trade blow hard across its fertile cane fields, the far north Queensland sugar town of Mossman is fighting for its life.

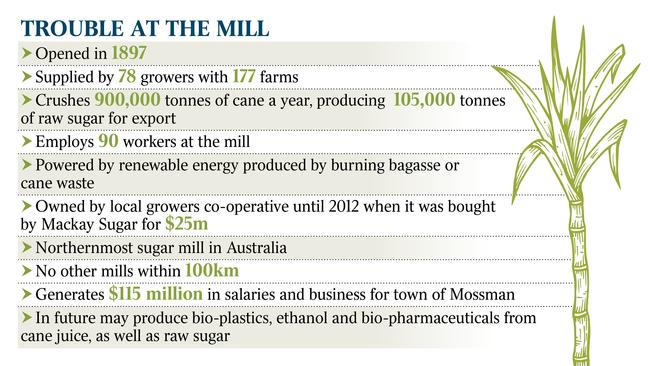

At stake is the future of its 120-year-old rusting sugar mill, the biggest employer in town and the heart of this thriving community nestled in a bowl of patchwork farms ringed by tropical rainforest, lush mountains and deep gorges 100km north of Cairns.

Mill owner Mackay Sugar, battling a huge debt load and likely to be soon swallowed by a Brazilian sugar corporation, has cast the ageing Mossman mill adrift to focus on its three struggling sugar mills near Mackay.

It has told the 80 farmers who supply the ageing Mossman mill with 900,000 tonnes of cane a year that unless the mill is sold before November, it will shut down at the year’s end.

Without a Mossman mill, which employs 90 people directly, supports more than 50 town businesses and adds $115 million to the local economy every year, it will no longer be viable to grow sugar cane in this most northern agricultural pocket. The closest other sugar processing plant is an uneconomical 100km away near Mareeba.

The mill’s closure would spell the end of the cane industry between Mossman and Cairns, with no alternative crop options.

But Mossman is not a community afraid of a challenge. Local canegrowers are moving to buy and run the mill themselves.

Mossman canegrower Liza Giudice says farmers are tired of the uncertainty about their farming future and prepared to commit more than $20m over the next 10 years to upgrade and reinvigorate the Mossman mill.

“We’ve all agreed to go for it; we want to take control of our own destiny and secure our future as canegrowers and the best way to do that is to go back to our roots and run the mill ourselves,” Ms Giudice said yesterday.

“A cane farmer needs a local mill and a mill needs farmers. If we don’t work together and help each other out there won’t be a cane or sugar industry around Mossman any more.”

Buying back the mill and returning it to grower ownership is contrary to recent tides in Australia’s $2.6 billion sugar industry that have seen 15 of Queensland’s 20 sugar mills fall into foreign hands in the past decade.

The big Tully sugar mill south of Cairns is owned by Chinese government food giant COFCO. Thailand’s giant Mitr Phol owns four MSF sugar mills clustered mainly between Cairns and Innisfail, while Asia’s biggest agribusiness Wilmar snapped up CSR and its dominant eight mills along the Queensland coast for $1.75bn eight years ago. Bundaberg Sugar’s two mills belong to Belgian Finasucre. Only the Isis mill at Childers, near Bundaberg, remains Australian and grower owned.

The big-picture Mossman plan, backed by the local council, is to modernise the mill so it can produce not just 100,000 tonnes of sugar a year and its own electricity from cane waste, but also clean, green, high-value biodegradable “bioplastics” and biopharmaceuticals from plant-based sugars in the crushed cane. But keeping the mill running as well as adding the “bio-pharma” precinct will cost between $40m and $50m over a decade.

While growers like Ms Giudice are prepared to contribute half the mill’s ongoing operating and conversion costs, $20m is desperately needed from the federal government in the next two months, before the growers’ purchase deal with Mackay Sugar expires and the mill shuts. The state government is being canvassed for $10m.

“We’ve done the research and we know we can make this mill work,’’ said Ms Giudice, a director of the new grower milling company. “We’re not looking for a handout — we are putting our hands in our own pockets to contribute nearly half of those funds — but the simple fact is that without the Mossman mill there would be no town, no jobs and no cane farming left around here.”

To join the conversation, please log in. Don't have an account? Register

Join the conversation, you are commenting as Logout