Alkane Resources in $1bn pitch for aerospace funding

Miner Alkane Resources has a rare-earth material that can heat-proof jet engine turbines.

Mining outfit Alkane Resources is in talks with some of the world’s largest aerospace companies to help finance a $1 billion production facility to extract a rare-earth material that could greatly improve the heat resistance of jet engines.

Perth-based Alkane Resources, a gold producer generating cashflow of $25 million a year, is ready to chase $1bn in funding to make its Dubbo zirconia and rare-earths project the world’s largest producer of hafnium, a rare-earth mineral that can be used to boost the heat resistance of super alloys used in jet engine turbines.

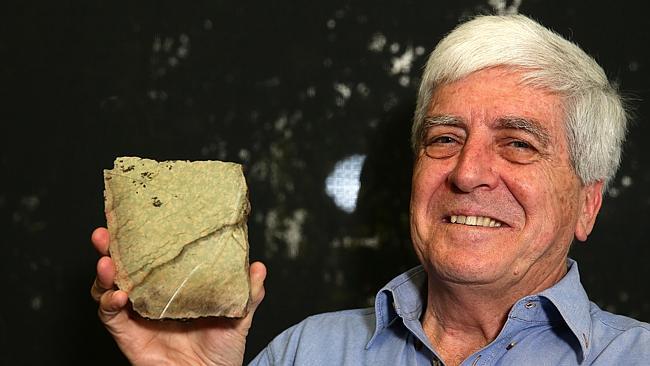

“We are certainly talking to aerospace companies about coming on as strategic partners and investors because these are the guys who have long-term requirement for our products,” Ian Chalmers, an Alkane director since 1986 and its managing director since 2006, told The Australian. “There is potential for these strategic guys to come in on the funding side. We are having those discussions right now.”

Mr Chalmers said Alkane had been talking with the world’s leading aerospace companies including Pratt & Whitney, Lockheed Martin, Honeywell, Rolls-Royce, Airbus and Boeing since last year about taking a strategic position in the company and is prepared to sell two or three large stakes to get funding.

“We have a major deposit here that can produce for the next 80 to 100 years in a relatively stable country. We tick all those boxes for a strategic stake from an aerospace company,” he said.

“We’ve spoken to virtually every aerospace company and you can understand their concerns that we are not in production yet.

“We’re still two years out from production but when we do come on stream, we will be a big player in the hafnium market and an important partner to these aerospace companies.”

Hafnium is increasingly being sought by the aerospace industry for its use in super alloys, which are used to increase the heat resistance of jet engines, allowing them to run from 1400C to 2000C without loss of structural integrity.

Ability to sustain high heat is important for jet engines, particularly as advances in technology increase their thrust and heat output.

“That means better fuel efficiency, more energy output and less emissions,’’ Mr Chalmers said.

The Dubbo facility, in central NSW, will also produce other rare-earth elements such as niobium, tantalum and zirconium, in which hafnium is found.

“Almost all hafnium production comes as a byproduct from producing pure zirconium and that’s because the two materials occur in nature together at about a 50:1 ratio,” Mr Chalmers said.

The rare material has been in use since the 1960s, when it made its most famous appearance on the main engines of the Apollo lunar modules, which were composed of 89 per cent niobium, 10 per cent hafnium and 1 per cent titanium.

Mr Chalmers said that once the Dubbo operation was at full production (expected to be in the second half of 2018) it would be able to make about 200 tonnes of hafnium a year.

The going rate of hafnium fluctuates between $US1000 and $US1200 a kilogram. Using a $US500 benchmark assumed in its feasibility study revenues for Alkane could earn $US100m a year by 2020.

Located 25km south of Dubbo at Toongi, Alkane’s Dubbo Zirconia Project has been a long time in the making.

If funding can be secured, Mr Chalmers expects the mine to more than double the world’s supply of hafnium.

“Because of increasing demand in aerospace applications, particularly in jet engine production, demand is outstripping supply of hafnium that we can produce,’’ he said.

“But when this is up and running at full production we will more than double the world’s supply of hafnium and we will be able to produce without too much difficulty about 200 tonnes a year.”

To join the conversation, please log in. Don't have an account? Register

Join the conversation, you are commenting as Logout