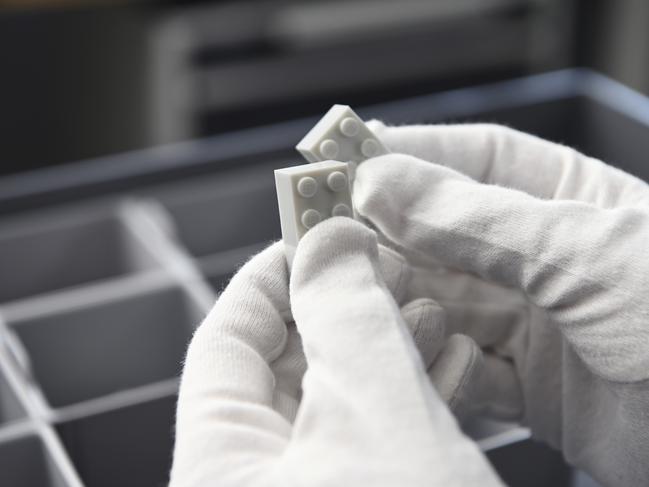

LEGO reveals prototype for brick made from recycled plastic bottles

Australian children could soon be playing with a very different kind of LEGO as the firm revolutionises its famous bricks.

Sustainability

Don't miss out on the headlines from Sustainability. Followed categories will be added to My News.

Exclusive: Australian children could soon be playing with LEGO made from recycled plastic as the toy giant expands its green credentials.

The new recycled prototype brick, which uses PET plastic from discarded bottles, is the company’s latest step in its journey to make LEGO products from sustainable materials.

It is the first brick made from a recycled material to meet the Danish-based toy giant’s strict quality and safety requirements, including “clutch power” – the classic LEGO tubes and studs design that allows the bricks to interlock.

A team of more than 150 engineers and scientists in Denmark have been working on the environmentally friendly brick for more than three years, testing over 250 variations of PET materials.

The new recycled bricks will “work perfectly” with existing LEGO bricks and should be on Australian shelves within 18 to 24 months, Tim Brooks, Vice President of Environmental Responsibility at the LEGO Group, told News Corp Australia.

The company prides itself on the way its bricks are handed down from generation to generation - bricks that were manufactured in the 1950s are still compatible with those produced today.

“We know kids care about the environment and want us to make our products more sustainable,” he said.

“Even though it will be a while before they will be able to play with bricks made from recycled plastic, we want to let kids know we’re working on it and bring them along on the journey with us.”

The discarded bottles are sourced in the US, with a one-litre plastic PET bottle providing enough raw material for ten 2 x 4 LEGO bricks.

The recycled brick is the latest move in LEGO’s vow to make its products more sustainable by 2030.

In 2020, the company announced it will begin removing single-use plastic from its boxes.

In 2018, it began producing elements from bio-polyethylene (bio-PE), made from sustainably sourced sugarcane.

Mr Brooks said LEGO was “committed to playing our part in building a sustainable future for generations of children”.

“We want our products to have a positive impact on the planet, not just with the play they

inspire, but also with the materials we use,” he said.

“We still have a long way to go on our journey but are pleased with the progress we’re making.”