Gold Coast stone benchtop trainees based in Victoria allowed to dry cut at government learning facility, WorkSafe investigating

Gold Coast apprentices say they’ve been exposed to potentially deadly silica dust while dry cutting during training in Victoria.

Gold Coast

Don't miss out on the headlines from Gold Coast. Followed categories will be added to My News.

APPRENTICES in Victorian TAFE courses are being taught how to dry cut sandstone that contains high levels of potentially deadly silica dust. Some are allegedly not wearing masks.

La Rocca Marble & Granite’s regional manager Debbie Clark said she was disgusted to learn her Melbourne-based apprentices were being exposed to the killer chemicals at the government-backed training facility, Holmesglen.

She has written to the federal and state governments asking why one student was not wearing a mask and another’s mask was not P2 filtered.

WorkSafe Victoria said it was investigating.

“You could cut the air with a knife with the amount of dust in the room,” Ms Clark said. “We send our boys to learn at TAFE, to learn a trade and to hopefully show them the right way of learning without putting themselves at risk.

“I’m furious. We have a duty of care to ensure our boys’ safety at work and if they go to TAFE and breathe this silica in and get silicosis as a result then who is going to pay for them when they are diagnosed and or dying?”

Ms Clark said employers were obligated to pay for the air monitoring and health assessments for authorities and it was “double standards” that government-backed training centres did not.

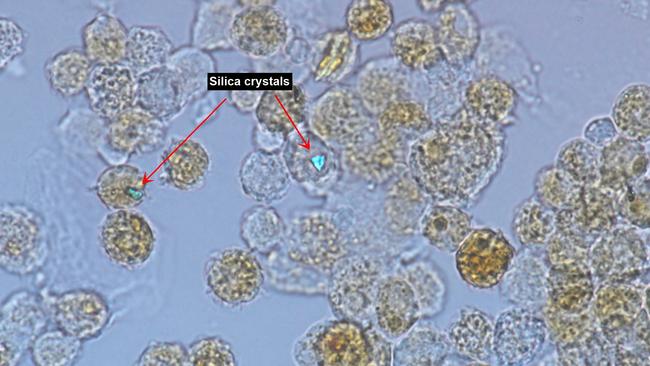

Silicosis is an incurable disease causing the scarring of the lungs and hampering the ability to breathe. It can be terminal. Queensland was the first state to ban the dry cutting of artificial engineered stone in 2018. Victoria followed in 2019 and New South Wales in 2020. Dry cutting on sandstone is not outlawed.

Engineered or man-made stone contains up to 90 per cent silica dust, and while sandstone is a natural product it contains up to 70 per cent of naturally occurring crystalline silica.

Associate dean of building construction and trades at Holmesglen, Elizabeth Jansz, said the health and safety of students and staff was the educator’s top priority.

“We take these incidents very seriously,” she said. “We are doubling down on our safe-work practices by providing more training, increasing supervision and installing more safety equipment.”

It is understood Holmesglen only dry cuts stone that requires ornate 3D carving for historical restorations and that apprentices are inducted and briefed on all safety equipment, including the requirement to wear fitted P2 or P3 masks at all times when cutting.

By mid-September it aims to buy vacuum-assisted power tools, provide more detailed training on the correct fitting of face masks and implement atmospheric monitoring.

So far this year, WorkSafe Victoria has conducted 368 workplace inspections relating to crystalline silica and issued 159 enforcement notices.

Ms Clark said La Rocca’s Melbourne branch was fully compliant with safety regulations for silica dust, with nil silica detected during its most recent air-monitoring compliance check.

Derick Brosnan has owned La Rocca Marble since 2011 and has spent more than $100,000 to ensure his Arundel workshop complied with all health and safety obligations as required by Workplace Health and Safety Queensland’s stone benchtop code of practice. The business also favours working with lithostone, a product that contains about 3 per cent silica dust.

“We also now have machinery that does the work of arising the edges of the stone which takes the hand polishing out of the equation, providing less exposure to the workers,” he said.

99 WARNINGS IN COAST STONE STING

August 11

ROGUE Gold Coast stone benchtop fabricators are still exposing workers to unacceptable levels of potentially deadly crystalline silica.

The state’s safety watchdog says it issued 99 enforcement actions to Gold Coast companies following a safety audit from August 2020 to May this year.

Workplace Health and Safety Queensland investigated 158 workplaces, including 45 on the Gold Coast, following widespread noncompliance of the stone benchtop code of practice that aims to protect workers from inhaling respirable crystalline silica found in engineered stone.

It comes as Queensland’s silicosis crisis deepens, with 198 stonemasons now battling the potentially deadly lung condition.

That represents an increase year-on-year of 24 cases.

According to WorkCover statistics, the government department has completed health screening of 1053 stonemasons exposed to crystalline silica dust from engineered stone. One is yet to complete the process.

Of these, 243 people were diagnosed with a work-related condition and all but 13 of them have been diagnosed with either silicosis or severe silicosis (progressive massive fibrosis).

The workers are being given help with their recovery and rehabilitation and provided compensation for their loss of wages.

Meanwhile, all 158 known stone benchtop fabrication workplaces across Queensland have finally be assessed by Workplace Health and Safety Queensland.

A spokeswoman said this resulted in 365 enforcement actions to stonemasons, 99 of which were given to Gold Coast businesses. This included three prohibition notices, seven infringement notices, 86 improvement notices and three immediate compliance notices.

Since the audit finished in May, WHSQ has undertaken 72 follow-up visits.

“The Queensland government is continuing its nation-leading response for workers with occupational dust lung disease, particularly those with coal workers’ pneumoconiosis (CWP) and silicosis, by offering a $5m medical research grant over four years from 2021 to 2023,” she said.

“A code of practice is also being developed for the management of silica in the construction industry.”

The Lung Foundation Australia has backed stronger regulation of the artificial stone benchtop industry and called for a total ban on high-silica materials within two years.