Silicosis epidemic Qld’s worst industrial health crisis since asbestos

The worst industrial health crisis since the deadly asbestos epidemic is taking hold in Queensland, with one in 10 workers in this sector being diagnosed with a fatal disease.

QLD News

Don't miss out on the headlines from QLD News. Followed categories will be added to My News.

THE worst industrial health crisis since the deadly asbestos epidemic is taking hold in Queensland, with one in 10 stonemasons being diagnosed with the fatal disease silicosis.

The rate of silicosis detections has escalated, alarming medical experts who say thousands of workers in the benchtop manufacturing industry are at risk nationwide.

Workers paying the ultimate price

Leading respiratory experts are calling for an urgent investigation into how engineered stone products — used in kitchens, laundries and bathrooms all around Australia — were allowed into the country without adequate protections for workers.

Nearly 700 Queensland stonemasons, who for decades have been cutting the products with little to no protection, have requested health screens, and by December 14 WorkCover was supporting 69 who had received a deadly silicosis diagnosis.

Many are aged in their 20s to 40s.

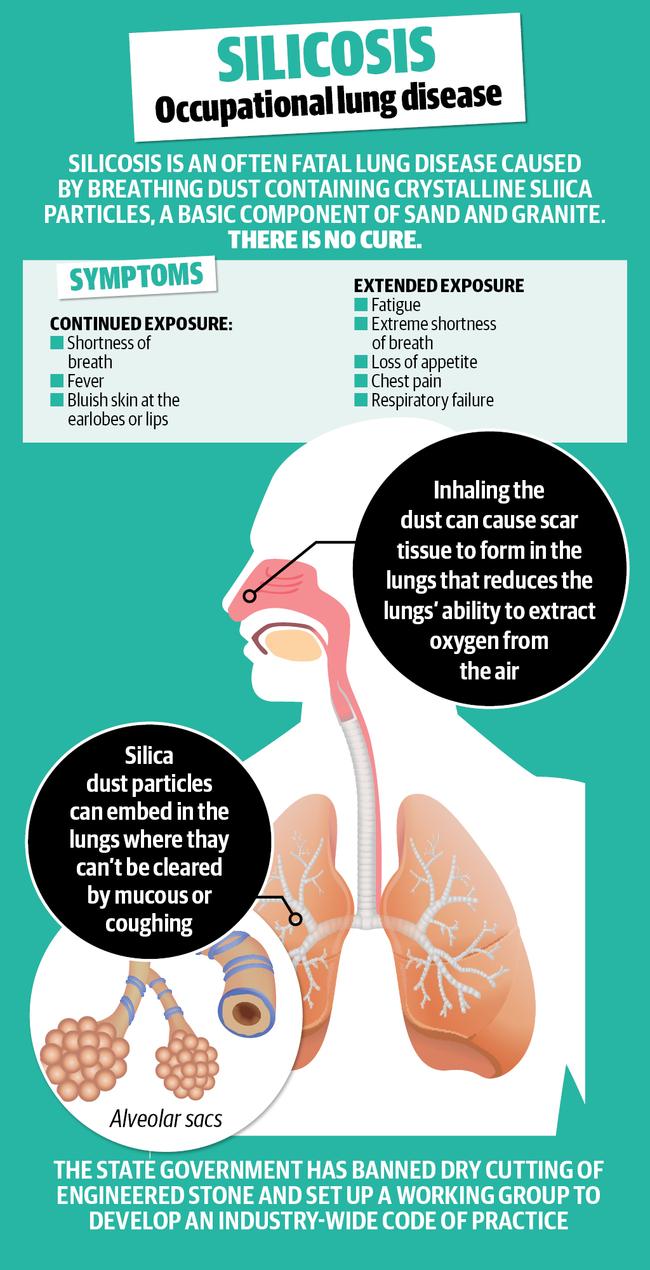

Silicosis — a disease once prevalent in the mining industry — returned to Australia from the early 2000s when stone benchtops became popular in many homes.

Engineered stone is made of processed quartz, which can contain up to 90 per silica.

When the product is cut, plumes of silica dust are released and if ingested can lead to silicosis, an irreversible scarring disease of the lungs, as well as lung cancer and kidney diseases.

Acute silicosis can develop within weeks of exposure to very high levels of silica dust.

The life expectancy for those with the most aggressive condition, progressive massive fibrosis, is as short as three years.

Queensland stonemasons were directed to get urgent check-ups in September after a silicosis cluster was discovered in the state — with 12 of 35 workers in just two businesses diagnosed — stunning the industry.

The rate of silicosis detections in Queensland has alarmed medical experts who are warning the results will likely be replicated around the country with thousands of stonemasons at risk.

Leading respiratory specialist Ryan Hoy from Melbourne’s Cabrini Medical Centre said the return of silicosis, a disease once prevalent in the mining industry, was Australia’s worst preventable occupational health issue in living memory.

“As a respiratory physician it is unthinkable that in modern Australia we are faced with re-emergence of silicosis as a major health problem,” he said.

“It clearly demonstrates that there have been major failings in the systems in place to protect workers heath.”

Dr Hoy said it remained unclear if there was a safe way to cut the products.

The Queensland and Federal governments are at odds over who would be responsible for banning the products.

The Sunday Mail has been told the issue is highly sensitive, with government and industry scrambling to understand the scale of the problem.

State Industrial Relations Minister Grace Grace issued an urgent safety alert in September when her department raised the alarm.

The Royal Australasian College of Physicians has estimated at least 1000 Queensland stonemasons are at risk of accelerated silicosis.

Ms Grace swiftly banned dangerous practices such as dry cutting, and instigated a working group to develop an industry code of practice.

She said the code was well advanced and would be finalised as soon as possible.

The Queensland response has been praised as the most proactive in Australia, and Ms Grace has been pushing her federal counterpart Kelly O’Dwyer towards a co-ordinated national response.

Ms Grace said she had asked Ms O’Dwyer to restrict or control imports of engineered stone but that had been rejected.

“I have again asked her to consider the measure,” she said.

It is understood a national import ban would only be implemented to support a domestic ban on the manufacture and use of engineered stone products, which would require the agreement of all states and territories.

Ms O’Dwyer said the Federal Government was deeply concerned about the re-emergence of silicosis and the deadly impacts of inhaling silica dust.

“This is a preventable disease, and Australian workers must be safe when working with these products,” she said.

“While this is primarily a matter for state and territory governments, the Government has been progressing urgent action to address these concerns.”

She said Safe Work Australia was working with the states and territories to develop initiatives to reduce exposure to respirable crystalline silica in the workplace.

COAG health ministers have committed to creating a national dust diseases register which would include silicosis.

Workplace Health and Safety Queensland officers have been urgently auditing about 150 stone benchtop manufacturers operating in the state.

About 130 audits have been completed since late September with authorities issuing 550 statutory notices for breaches such as uncontrolled dry cutting, health monitoring, provision of respiratory protective equipment, and inadequate dust control measures.

Shine Lawyers dust disease expert Roger Singh said urgent and co-ordinated action was required at ministerial level to eradicate dangerous work practices.

“We need to safeguard against another asbestos-type legacy looming over workers and their families in Australia,” he said.

He has called for all workshops to be licensed with operators required to install water injection systems to eradicate all airborne dust, exhaust ventilation systems and tailor made face masks that stop all dust inhalation.

WorkCover Queensland CEO Bruce Watson said the recent spike in silicosis claims had been significant, and was stressful on stonemasons and their families.

He said WorkCover was funding all costs associated with the immediate health screening of anyone who works or had worked in the industry.

He said the office was also studying the latest research into the most effective treatment and recovery options for silicosis.

“Supporting this research is important because we understand that many workers and their families still have unanswered questions about this terrible disease,” he said.

Trendy stone’s fatal attraction

GOLD Coast stonemason Scott Newall was overseas when he first saw a piece of engineered stone.

“I’d never seen anything like it. It was black and had all these mirrored shiny things through it and I was quite mesmerised by it,” the 45-year-old said.

By the time he returned to Australia in about 2001, the shiny new product was mesmerising an entire nation as hordes rushed to cover kitchen, bathroom and laundry benchtops with the designer slabs.

“Everyone went into engineered stone so quickly. Just bang, it exploded and the next minute that’s all you’re working with,” Mr Newall said.

About three months ago, Mr Newall, the father of three children under eight, was told his lungs were coated with toxic dust and had a maximum of five years left in them. He was ordered to stop work and was put on worker’s compensation.

The diagnosis came as a shock, although he had noticed his health had been failing for a while, especially when lugging heavy island benchtops up flights of stairs, a task he had once done withy ease.

“I was nearly having a heart attack every time and feeling like I was pretty much going to die,” he said.

“That made me feel like my time was coming but I’m sort of glad it’s out in the open.

“Otherwise I probably would have just kept plugging away with it undetected until I died.”

Since the diagnosis, his family has been under severe stress, with their future thrown into turmoil.

“It’s hard being the unknown, hard to set up for what you want to do with your kids; will you be able to afford karate in six months, will you be able to afford gymnastics in six months. You just don’t know,” he said.

Mr Newall is waiting to meet with a doctor about options for a lung transplant. And he still has little clarity on what will happen when his compensation payments stop after six months.

“I feel more sorry for my wife than I do for me,” he said.

“I’ve always done the right things with my houses so there’s not a big mortgage for her, but obviously I don’t want her to have any big bills when I’m not here.

“I want her to have a good life.”

Mr Newall said engineered stone products should be banned from Australia as they were too toxic to work with safely.

Danger lurks in workshop, not kitchen

THE health dangers of cutting engineered stone products were known from day one, with two of Australia’s largest suppliers saying they had warned stonemasons for almost two decades to protect themselves.

But a leading respiratory specialist said there was still insufficient evidence to prove that the products could be cut and used safely.

They do not pose any risk once installed in homes.

Dr Ryan Hoy, from the Cabrini Medical Centre in Melbourne, said authorities needed to launch a full investigation into the products to determine whether they could be used safely.

“The most effective approach to controlling the risk in this industry is to use one of the many alternative materials for benchtop fabrication that does not have a high silica content,” he said.

“If engineered stone is used, there needs to be extremely high-level, sophisticated dust control measures in place and frequent, objective monitoring of dust levels to demonstrate that they are continuously below the regulated standard.”

Quantum Quartz general manager Mark Norman said the company began selling engineered stone in 2000, and the health dangers were known from the start.

“The silica issue was well known throughout the industry,” he said.

Safe cutting methods outlined in product manuals given to stonemasons in 2000 remain virtually the same 18 years later.

Mr Norman said each slab of engineered quartz sold had silica warning labels attached and every invoice issued was stamped: “Silica Warning BEWARE.”

He said the material was completely safe when cut following guidelines, and he encouraged reviews of facilities and procedures.

Caesarstone Australia managing director David Cullen said the company had actively promoted and educated safe handling.

“Caesarstone quartz surfaces comply with the strictest local and international safety standards and are completely safe installed in any environment,” he said.