Teys' Lakes Ck expansion to trial beef boning bots

Cost of boning Australian beef among highest in the world: new research facility deliver $30 a head benefit

Rockhampton

Don't miss out on the headlines from Rockhampton. Followed categories will be added to My News.

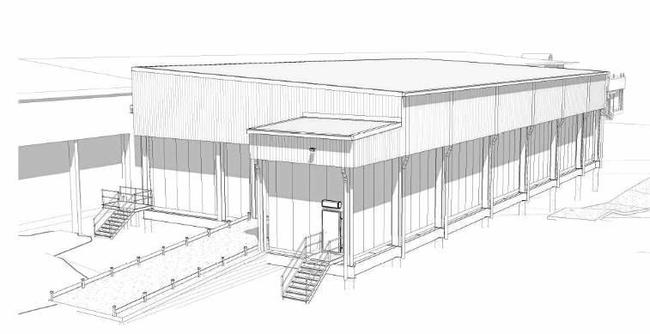

TEYS Australia's new Lakes Creek research and processing facility will house Australia's first automated beef boning technology.

The five-year expansion worth $32.4 million, will be co-funded through the MLA Donor Company by Teys Australia, the Federal government and the Australian Meat Processor Corporation.

The North Rockhampton site was chosen because it allows for building without disrupting normal processing, and because it has previously trialled the DEXA technology which was designed for use in lamb processing.

The facility's robots will make a series of cuts on each carcase, including both bone-sawing functions and muscle-cutting, in order to simplify and improve the manual processes which follow.

The placement of some of those cuts are considered critical in ensuring that maximum value is retained in each carcase. Similar trials on lamb carcases has proven that robots perform these functions more consistently than manual operators, and will perform the 'right' cut, time after time.

Current industry practice is to expose the striploin, after which grading can be performed whether manually or using a camera.

Through the application of scanning, robots may seek out "finer carcase characteristics” prior to cutting.

As the systems prove themselves off-line, they can then be taken into Lakes Creek's commercial production line for on-line trials.

MLA Managing Director Jason Strong said with Australia having one of the world's most expensive processing sectors, automating beef boning would reduce per head operating costs for the benefit of the entire Australian industry.

"Maximising the value of carcasses through accurate cutting along with the increase in productivity through continuous flow in the boning room is vital to the sustainability of the Australian red meat industry," Mr Strong said.

"Beyond movement in livestock prices, the single biggest impact on processing efficiency is the accurate segmentation and deboning of carcases into the highest primal value possible. It's where the most significant improvements in processing industry efficiency can be made.

"Beef boning automation has been estimated to deliver at least a $30 per head benefit, with an estimated 40% of this benefit to return to producers.

"The developments will also provide a platform for other value adding outcomes, such as increasing producer feedback through DEXA and CT installations.

"We are seeing the benefits of lamb boning automation in Australian processing plants, with carcase values increasing by more than $6/head. More than 40% of large processing throughput now uses the technology, and pending installations will raise this to 71% of throughput."

"MLA has conceptualised a revolutionary, global and scalable design for beef boning automation, and with industry partners, it will now make Leap4Beef a reality."

Mr Strong said MLA had undertaken industry consultation with more than 20 processors on beef boning automation, and will continue to work with other Australian processors and hold regular updates.

"The beef boning automation R&D room will be available for any solution provider to develop MLA/Teys approved initiatives and will be open for Australian processors to visit to see the developments and evolution of the technology," Mr Strong said.

Teys Chief Value Chain Officer, Tom Maguire said, "Beef processing is one of Australia's largest manufacturing industries employing thousands of Australians in rural and regional communities and this type of investment will help us secure its future for the long term."

"Around that world manufacturing has shown that it can maintain a competitive advantage provided it adopts the latest technologies and embraces the digital economy. There is no reason that the beef processing industry cannot be part of this," said Mr Maguire.

Mr Maguire said that Teys commitment to the project was because Australian cattle producers produce some of the best product in the world, and a modern, efficient and productive processing system can ensure we maintain this position in the future.

"Automation of critical beef cutting lines has the potential to greatly improve consistency and quality of product offered to customers whilst improving the working conditions in our plants," Mr Maguire explained.

"While we have much work to do to deliver an outcome, we are committed to getting the best and brightest minds to work with us on the project and getting the job done."

The Australian Meat Industry Council's Cost to Operate report last year showed Excluding livestock purchases, the average cost per head incurred in processing beef in Australia is 24 percent higher than that in in the US, 75pc more than Argentina and more than 100pc higher than in Brazil. The report suggested that cost reduction was the only way the industry can compete with other global beef exporters.

Teys plans to hold a series of open days and demonstrations at the site as major milestones are reached.

Originally published as Teys' Lakes Ck expansion to trial beef boning bots