How sugarcane at Mackay’s Biocommodities Pilot Plant will tap into $700 billion industry

Hungry little yeasts and sugar will play a key role in a synthetic biology industry tipped to be worth $700b by 2040. Find out how Mackay will ‘take advantage’.

Mackay

Don't miss out on the headlines from Mackay. Followed categories will be added to My News.

Like the king’s daughter wove straw into gold for Rumpelstiltskin, Mackay sugar will transform into alternative proteins as part of a lucrative global industry tipped to reach $700 billion by 2040.

In a modern take on the aged-old process behind making bread and yoghurt, sugar will be fed to microorganisms — in this case fungus or yeasts — in a fermentation process that then produces alternative proteins.

GW3 CEO Kylie Porter said the “precision fermentation” at the Mackay Racecourse’s Renewable Commodities Pilot Plant fed into an insatiable, worldwide demand for synthetic protein for the manufacture of various foods.

“As the global population continues to increase, we literally do not have enough animal-based protein,” Ms Porter said.

“So we’re going to have to look at alternatives.

“It’s not about saying there isn’t a future for traditional sources of beef, it’s actually saying there’s room to grow complementary industries.”

Ms Porter said alternative, or synthetically-produced proteins, may sound “new age” but it was already big business, such as with Hungry Jack’s Rebel Whoppers, the burgers’ meatless patties ordered from plant-based company V2food.

CSIRO’s synthetic biology road map states the synthetic biology industry could be a “$700 billion global opportunity by 2040”, with $27 billion in annual revenue and 44,000 new jobs for Australia.

“Our region is ideally suited to take advantage of this,” Ms Porter said, adding the US was similarly turning biomass into value-added products with its corn industry.

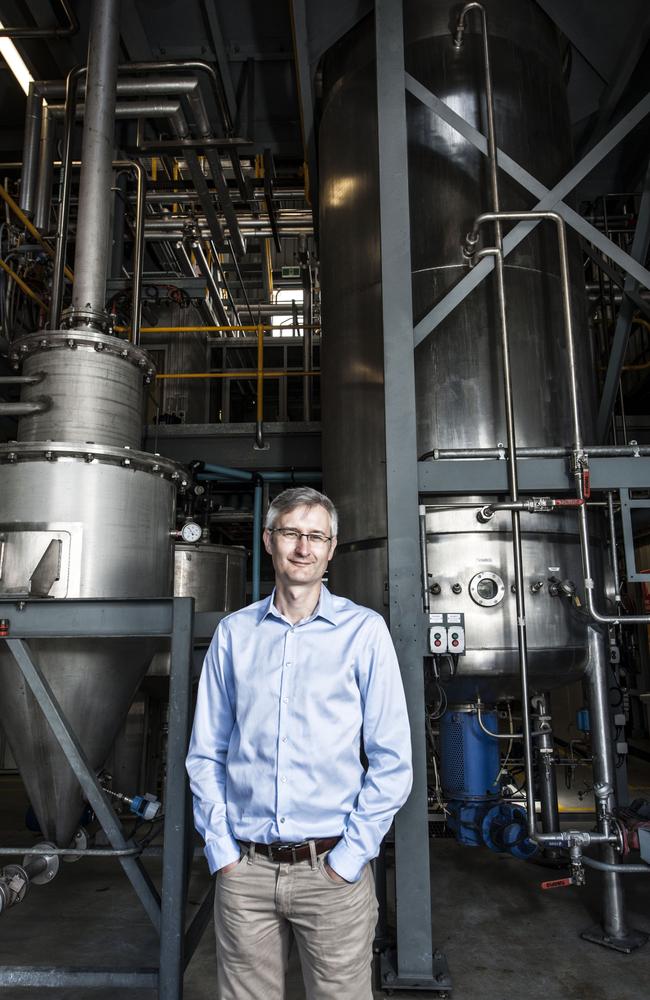

Queensland University of Technology’s Professor Robert Speight said thanks to a $5.2 million upgrade, hopefully completed in early 2022, the pilot plant could potentially create a “whole range of different products”.

“The world is your oyster, think of pretty much any product and you can either have an organism or engineer an organism to make that,” the microbial technology professor said.

Professor Speight said they would engage with the Mackay community and industries to choose what alternative proteins to manufacture with upgraded equipment giving more precision, higher yields and “stringent containment” to avoid unintentionally releasing organisms into the environment.

He said the plant was already working with new Canberra-based business Nourish Ingredients to have fungi make microbial oils giving its products healthy fats and the “sensory aspect”.

He said microbial oils could also produce biodiesel with US-based Mercurius Biorefining having partnered with the plant, QUT and the Queensland Government over the past decade to launch a biofuels operation.

And there is potential to create ingestible microorganisms for humans with the plant having successfully used sugarcane bagasse to produce livestock feeds and probiotics.

“We do a 1000L fermentation fed with sugar and grow up these bacteria that then becomes the probiotic,” Professor Speight said.

“The possibilities, especially with engineering biology, are almost endless.”

“The biofutures strategy has been attractive and is why a lot of international companies have looked at Queensland,” Professor Speight said.

CSIRO Professor future protein mission lead Michelle Colgrave said the bioindustry sphere was about creating circular economies by elevating the efficiency of existing food systems.

Professor Colgrave said most people thought about proteins as coming from animals but by feeding sugar to yeasts, they were engineering the “building blocks of life” via what is termed protein expression.

“Depending on the method of production, most companies will aim to make (a protein) that is identical to one you’d find in nature,” she said.

“We’ve been using the power of yeasts for tens of thousands of years and we’ve been kind of manipulating yeast to deliver specific proteins for the past 50 (years) or so.

“It’s been quite a commonplace activity in the pharmaceutical world,” she said adding some antibody therapies and vaccines were delivered via protein expression.

Professor Colgrave said being apply to use the science in agriculture depended on finding a scale of production that could provide a worthy return on investment.

It is hoped the Mackay Biocommodities Plant will do just that with Professor Speight estimating the upgrade would grow their team from about five people to up to 20 and in the future, support a hub and co-located bioindustry focused facilities.

“The logistics is an important aspect of it,” he said, adding opening up international export via Mackay was a “key component”.

“QUT is also developing new programs for training future employees for this industry.

“We can potentially be doing the teaching, training and learning in Mackay as well, or doing it remotely so (via) online learning.

“Watch this space.”