Engineering work begins for Project Ulysses at Cleveland Bay Industrial Park

A Townsville project looking to transform bioethanol into jet fuel and diesel has entered the next phase, but it needs 1100 workers to become reality. Get the latest update.

News

Don't miss out on the headlines from News. Followed categories will be added to My News.

An Australian-first alcohol to jet fuel production plant planned for Townsville is a step closer to reality, but a challenge looms in finding the thousand construction workers to build it, given the region’s workforce shortage and $36 billion pipeline of major projects.

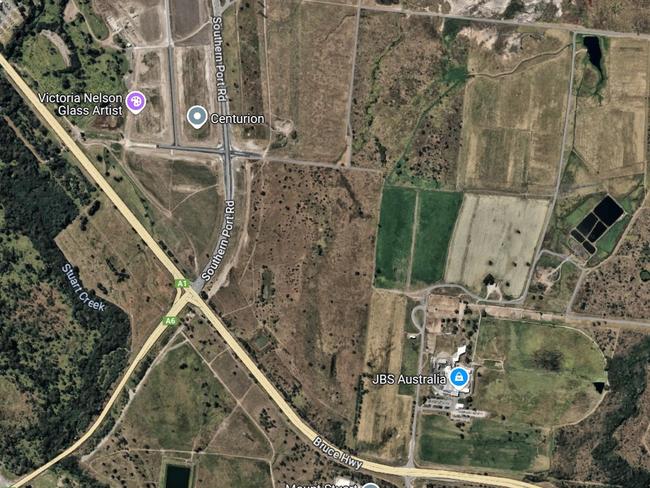

Jet Zero Australia’s proposed $600 million Project Ulysses biofuel refinery is planned to be built on a 20ha site in the Cleveland Bay Industrial Park on Colinta Rd, near the JBS meatworks.

It would use renewable power from Copperstring 2.0 and bioethanol created from wheat starch, shipped from New South Wales into the Port of Townsville.

Harnessing Alcohol to Jet (ATJ) technology developed by sustainable fuels technology company LanzaJet, the facility will produce 102 million litres of kerosene (Sustainable Aviation Fuel – SAF) and 11 million litres of renewable diesel annually.

In addition to the 1000 construction jobs, Project Ulysses could deliver over 100 direct skilled operational jobs, while contributing to Australia’s energy security by bolstering domestic jet fuel production while decarbonising the aviation sector.

Based on LanzaJet’s world-first facility at Soperton, Georgia, the refinery project has the backing of industry partners including Airbus, Qantas and Idemitsu as well as the federal government via the Australian Renewable Energy Agency as part of the Advancing Renewables Program and the state government through the Queensland New-Industry Development Strategy.

Townsville-based Jet Zero Australia industrial manager Adam Douglas revealed that engineering firm Technip Energies had been appointed to carry out the engineering design in preparation for a final investment decision in December 2025.

If given the green light, construction would begin immediately, with first fuel by late 2027.

He said Technip would look at a range of aspects, including how the plant was designed, constructed, maintained, operated, and what technology it would use.

“Some projects don’t spend much upfront (on engineering work), and then they get surprises. We don’t want to have any surprises,” Mr Douglas said.

“We’ve got a factory in America to model off, and we want to do all of the engineering work, right down to how we’re going to manage the waste streams … how we’re going to get the product in and out of the process, loading facilities, unloading facilities, and logistic plans. “There’s a lot of work to be done to get to a point where you say, ‘we’re ready to start construction’.”

While they were looking to construct much of the facility using fully-built modules that would be joined together on-site, Mr Douglas said “there’s a lot of equipment that’s got to be built locally” including the tank farm, boilers, air compressors, and hydrogen plants.

With years of experience working in NQ sugar mills, Mr Douglas could see the potential for harnessing the region’s sugar cane industry in the future.

“We’ve chosen the Townsville location because … it’s close to the port. Secondly, it’s the theoretical biomass centre of the sugar cane industry,” he said.

“But the demand for SAF is so strong that we’re going to need ethanol in the future for future projects. Qantas has got a 10 per cent self imposed mandate, and that’s about 600ML of fuel.

“We’re building 100ML of fuel in this facility so it’s 2 per cent. It’s really a drop in the ocean of what Qantas needs … (so) to meet their needs, we’re going to need significant quantities of ethanol and the Australian sugar industry is potentially one of those avenues.”

LanzaJet chief executive Jimmy Samartzis said Australia’s efforts to build a domestic SAF industry would help improve energy security and create jobs, setting a powerful example across the world.

“We’re grateful to be working alongside capable and innovative companies like Jet Zero Australia and Technip Energies to continue to progress the country’s first SAF project, proving the industry can scale beyond borders and lead the transportation sector’s ability to decarbonise,” Mr Samartzis said.

For more information, visit: jetzero.com.au.

More Coverage

Originally published as Engineering work begins for Project Ulysses at Cleveland Bay Industrial Park