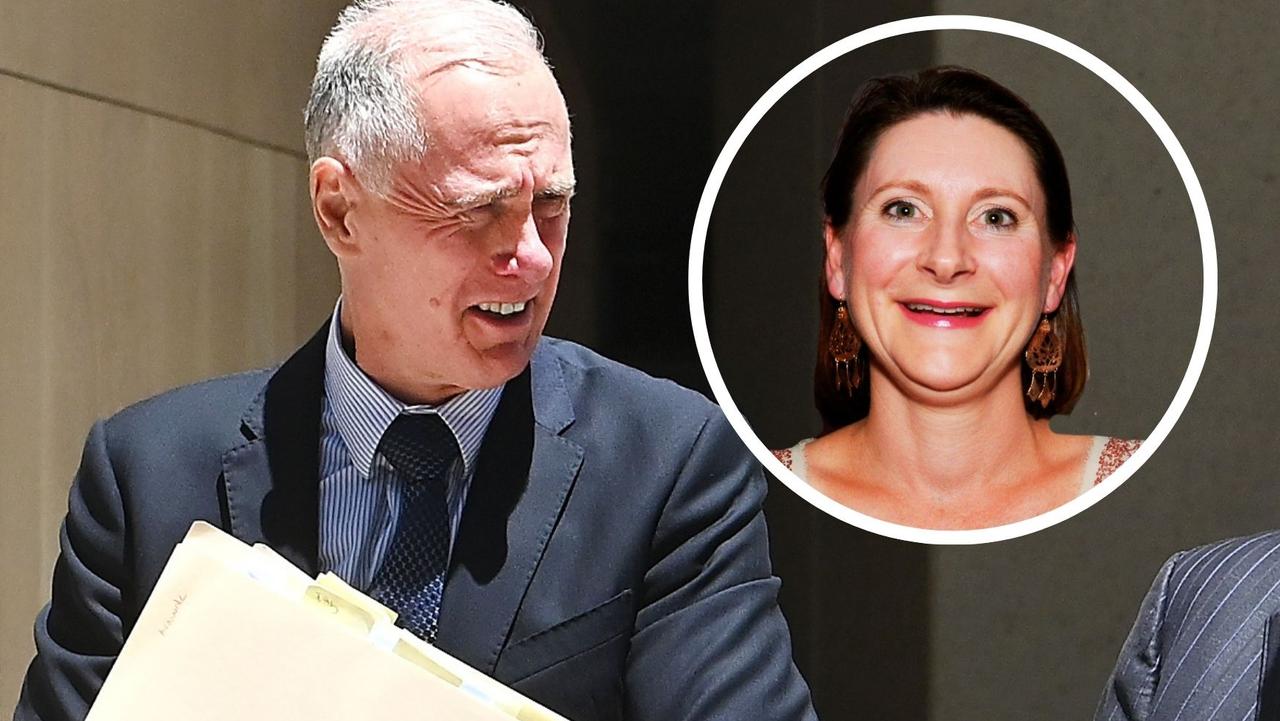

How Nev Power will use his Queensland farming background as the head of the PM’s National COVID-19 Coordination Commission

The man handpicked by the PM to head the National COVID-19 Coordination Commission is using his Queensland farming background to help get the country through this crisis.

QLD Business

Don't miss out on the headlines from QLD Business. Followed categories will be added to My News.

Nev Power was given early lessons in the vagaries of nature growing up on his family’s Queensland cattle station. Now the 61-year-old mining executive is using those lessons in the battle against coronavirus as head of the National COVID-19 Coordination Commission, given the task of ensuring Australia has enough resources to effectively fight the pandemic.

“Farming taught me that you have to be resourceful and always have to be looking at whether your business is as good as it possibly can be,” says Power of the cattle property south of Mt Isa that remains in family hands. “You are always battling things like the weather so it’s tough.”

Power attended Mt Isa High School and later became an apprentice fitter and turner at Mount Isa Mines (MIM). He went on to a 20-year career at MIM before joining Smorgon Steel in Melbourne.

Brisbane lured him back for a period when he took up a role working for Thiess, where he championed an indigenous employment program and rose to become CEO of the engineering firm’s Australian operations.

More recently he joined Andrew “Twiggy” Forrest’s Fortescue Metals where he was chief executive for seven years until 2018.

Power, who now lives in Western Australia where he chairs Perth Airport, remains a Queenslander at heart and returns to the family property several times a year to help with aerial mustering.

His resume obviously impressed Prime Minister Scott Morrison who said on his appointment last month that his corporate background meant “he knew how to solve problems, and big ones.”

The commission has already played a vital role in unblocking supply chains to ensure vital shipments of things like masks and medical equipment can reach Australia from overseas during the pandemic.

“The key has been to restore these fractured supply chains,” Power says. “There has been a focus on smoothing operations at ports.” Remote rural and Aboriginal settlements that often have to order food supplies in bulk also have been helped.

“There has been a huge effort by both the government and business in trying times,” says Power, adding he is particularly impressed by those manufacturers nimbly pivoting to make personal protection equipment (PPE) and other medical supplies that previously had to be imported.

Power says we are now living in a world where coronavirus, and its impacts, will linger for some time. That will mean changes in how we work and how companies operate.

“There will be high awareness of (hygiene) and the need to work on protocols as the economy comes back and international tourism gets moving again,” he says.

The commission is working on developing guidelines for businesses when they reopen including social distancing and other issues around stopping the spread of the virus.

“We need to create COVID-19 safe workplaces,” he says. “It could be things like reducing density at restaurants and at workplaces. You are already seeing it in the mining industry. They are separating people when they move them onto mine sites. It is also happening in the food processing sector.”

Power see an opportunity after the pandemic to restructure the Australian economy in vital sectors such as manufacturing so it is better placed to ride out future shocks. “Part of my role is to look at how we can emerge from the virus stronger and that may include restructuring our supply chains,” he says.

He says reliance on the country’s own internal resources for medical equipment and other health-related products rather than global supply chains could be a fillip for local manufacturing.

“The reason Australia imports so much product from overseas is that it is more efficient to do so,” he says. “We have not had a high level of investment in manufacturing and have seen a lot of our manufacturing capacity move overseas.”

Power says the high value of the Australian dollar, a small domestic market and high labour costs had been major reasons for that lack of competitiveness.

But with global supply lines seen as increasingly precarious that may be about to change. “With a lower Australian dollar and sustainably low energy costs we may be able to focus on products that we can make here,” he says. “We can invest in modern, efficient plant to build niche markets that don’t require huge quantities.” Power says examples would be fertilisers, agricultural chemicals and personal protection equipment (PPE).

Power adds that sustainable energy costs would be key to rebuilding the manufacturing sector. “There is no reason why Australia cannot have very reliable energy --- we have an abundance of most energy sources including coal, gas, solar and wind,” he says.