Flinders University’s super sponge soaks up oil, diesel spills

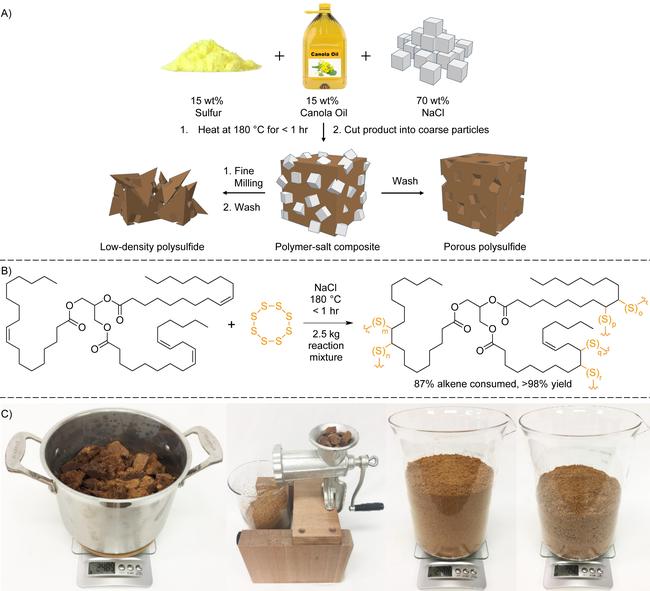

A FLINDERS University invention soaks up crude oil and diesel spills using an absorbent polymer made from waste cooking oil and sulphur, itself a byproduct of the petroleum industry.

SA News

Don't miss out on the headlines from SA News. Followed categories will be added to My News.

A MARVELLOUS mixture of industrial waste invented at Flinders University to mop up mercury also soaks up spills of oil and diesel, research shows.

Synthetic chemistry senior lecturer Dr Justin Chalker is leading the international team driving the research, which is published today in the journal Advanced Sustainable Systems.

“It’s pretty cool. It’s exactly the same material that we made for cleaning up mercury pollution,” he said.

“It turns out that that same substance is excellent for removing crude oil from water.”

The new type of rubber, made from waste sulphur, salt and plant oils, is cheap, elastic and porous just like a sponge.

Dr Chalker said he set out to find new uses for sulphur, a by-product of the petroleum industry that is stockpiled around the globe.

“So we are using waste from an industry that is linked to oil spill pollution in the first place,” he said.

“It’s an interesting idea about managing the life cycle of chemicals to help the environment.”

It works because the raw materials are “hydrophobic”, or water-hating.

“They don’t like to interact with water, they like to interact with oil,” Dr Chalker said.

“So the logical step was to see if you could use this material to remove crude oil from water, and it turns out that it works fantastically well.”

And it’s quick-acting, Dr Chalker said.

“The material works very rapidly too,” he said.

“As soon as you sprinkle the stuff directly on oil, it absorbs it and aggregates, which is very important for oil spill remediation.”

The absorbent polymer can be scooped up and squeezed out, to recover the oil and reuse the sponge-like material.

“We made this polymer into a porous material, so it looks and acts like a sponge,” Dr Chalker said.

“You can scoop out the oil polymer product because it forms a gel – you can actually scoop it out with a net from the water, so that’s pretty cool – but you can use it in a filter as well.

“Because it acts like a sponge, to get the oil back you can simply compress it and recover the oil and reuse the polymer.”

Dr Chalker is in the process of establishing a company to sell this material, driven by earlier successes in mercury remediation. Now there are two applications, maybe more.

He is named as an inventor on the patent and has field trials under way for mercury remediation, with the potential to pursue oil spill remediation trials as the opportunity arises.

The raw materials are produced in millions of tonnes each year, ready and waiting.