Glaciem ships southern hemisphere’s largest capacity heat pump to Melbourne

The southern hemisphere’s largest capacity heat pump will be shipped from Adelaide to a Melbourne fruit processing facility next week, and installed as part of a new integrated cooling and heating system designed to cut energy costs and reduce greenhouse gas emissions.

SA Business

Don't miss out on the headlines from SA Business. Followed categories will be added to My News.

- Glaciem Cooling Technologies wins $2m in federal funding

- How to get the most out of your Advertiser subscription

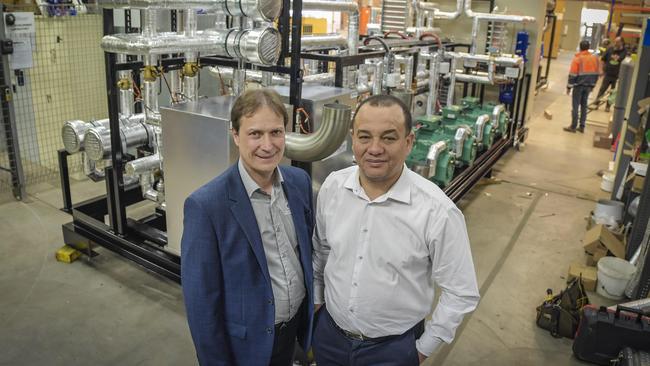

Adelaide company Glaciem Cooling Technologies has shipped the southern hemisphere’s largest capacity heat pump from its manufacturing facility at Mawson Lakes.

The CO2 heat pump will make its way to south-east Melbourne next week, where it will be installed at a new fruit processing facility operated by Montague - the country’s largest fruit storage, packing, and distribution company.

Glaciem’s cooling technology will be used for cold storage at the site while energy produced through the cooling process will be captured and used to generate hot water needed to clean apples at the site.

The heat pump has 726kW capacity for cooling and 1.1MW for heating - making it the largest capacity heat pump ever manufactured and shipped in the southern hemisphere.

It has enough power to deliver heating and cooling for a ten-storey building or supermarket.

Developed in collaboration with the University of South Australia, Glaciem’s technology is leading a shift away from HFC (hydrofluorocarbons) refrigerants to CO2.

Their system, which integrates thermal energy storage with renewable energy, is aimed at significantly reducing energy costs and lowering greenhouse gas emissions produced by the world’s heating and cooling industry.

Glaciem managing director Julian Hudson said unlike traditional refrigeration systems, CO2, when used at very high pressures, can transfer significant levels of energy using a very small amount of refrigerant.

He said the shipping of the heat pump was a major milestone in the commercialisation of the “world-first” technology.

“After passing proof of concept, it has been hugely exciting to see our technology deliver commercially,” he said.

“The heat pump being installed at Montague’s new facility will deliver immediate energy cost savings, but it will also make it one of the most sustainable.”

Glaciem tested its thermal energy storage solution with organisations including Pernod Ricard and Ceravolo Orchards after winning $2m in funding from the Federal Government’s Australian Renewable Energy Agency’s (ARENA) Advancing Renewables program last year.

The heat pump at Montague’s facility will be connected to a 4MWh thermal energy storage system, which will store the energy created by the heat pump and release it in the cooling process when needed.

It will form part of a smart system managed by Glaciem’s Advanced Control and Forecasting Algorithm (ACFA) software.

“As well as predicting and managing process demands and efficiency, the ACFA system will also enable Montague to predict available solar power and national electricity market power pricing in order to optimize energy use at the lowest cost and highest efficiency,” Mr Hudson said.

“In addition to the installation at Montague, we’re currently completing several other orders from major clients within the wine and beverage, entertainment and dairy industries.”

Lead researcher for the project, UniSA Professor Frank Bruno, said the project partners had been “guided by what industry needs” to deliver the low-cost, energy saving technology.

Montague managing director Scott Montague said Glaciem’s technology would meet the high temperature and demand requirements at the new processing facility.

“The design process will provide the most cost efficient and effective refrigeration system and hot water demand system known to exist in this type of production facility.”